Preparation method of black tea

A technology for black tea and tea leaves, which is applied in the field of black tea preparation, can solve problems such as inability to meet the needs of beverages, and achieve the effects of mellow taste, improved taste, and increased concentration of tea soup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

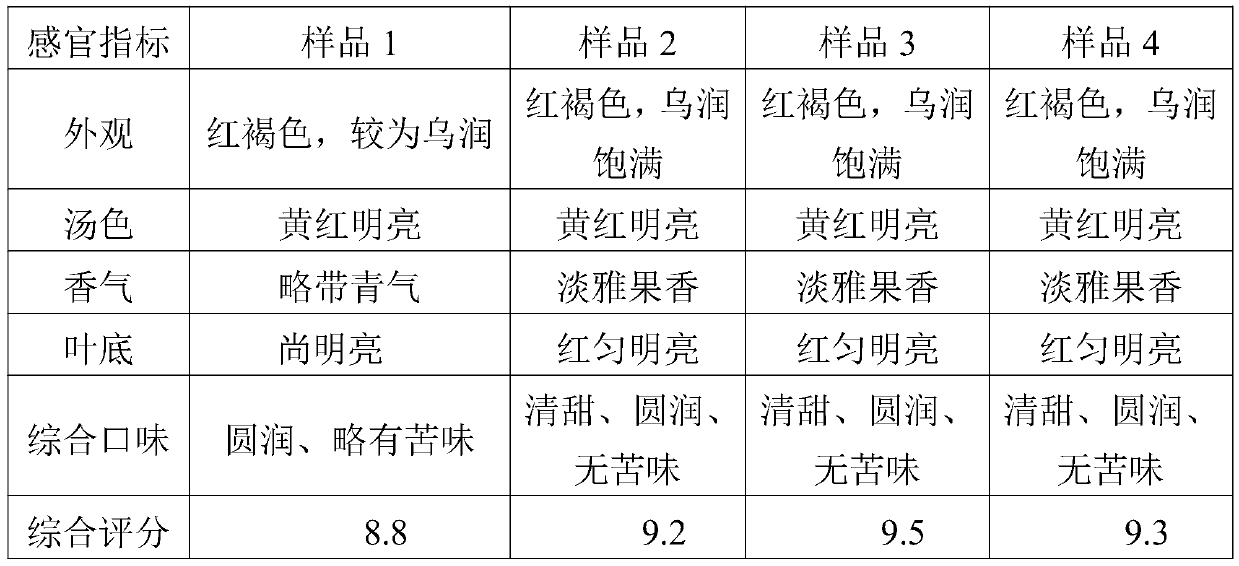

Examples

Embodiment 1

[0019] Put 10 kilograms of tea tree fresh leaves into the withering tank to wither, blow hot air into the withering tank, control the temperature of the withering tank at 35°C, and complete withering in 12 hours. Put the withered tea leaves into the kneading machine, mix them evenly and knead them into strips, take out the kneaded tea leaves from the kneading machine, put them into bamboo rafts, spread them to a thickness of 8cm, cover them with a damp cloth and put them in the fermentation room to keep Temperature 24 ℃, air humidity 92%, ferment for 5 hours. After the tea leaves are fermented, use a tea dryer to dry the tea leaves at a temperature of 85° C. for 20 minutes. The dried tea leaves have a sweet and mellow tea fragrance and can be packaged.

Embodiment 2

[0021] Put 10 kilograms of tea tree fresh leaves into the withering tank to wither, blow hot air into the withering tank, control the temperature of the withering tank at 35°C, and complete withering in 12 hours. Put the withered tea into the kneading machine, mix them evenly and knead them into strips, take out the kneaded tea leaves from the kneading machine, add 1 kg of rambutan enzymatic extract and 0.5 kg of cranberry enzymatic extract The rambutan enzymatic hydrolysis extract is a product obtained by enzymatic hydrolysis of rambutan pulp, and the cranberry enzymatic hydrolysis extract is a product obtained by enzymatic hydrolysis of cranberry pulp. The specific preparation method of Dan enzymolysis extract is: take 1 kilogram of rambutan pulp and add 1 times the weight of water to make a pulp, add cellulase and pectinase, a total of two enzymes, the total amount of the above two enzymes is 0.03 kg , enzymatically hydrolyzed at 60°C for 3 hours to obtain the product; the ...

Embodiment 3

[0023] Put 10 kilograms of tea tree fresh leaves into the withering tank to wither, blow hot air into the withering tank, control the temperature of the withering tank at 36°C, and complete withering in 10 hours. Put the withered tea into the kneading machine, mix them evenly and knead them into strips, take out the kneaded tea leaves from the kneading machine, add 1.5 kg of rambutan enzymatic extract and 1 kg of cranberry enzymatic extract The rambutan enzymatic hydrolysis extract is a product obtained by enzymatic hydrolysis of rambutan pulp, and the cranberry enzymatic hydrolysis extract is a product obtained by enzymatic hydrolysis of cranberry pulp. The specific preparation method of Dan enzymolysis extract is: take 1 kilogram of rambutan pulp and add 1 times the weight of water to make a pulp, add cellulase and pectinase, a total of two enzymes, the total amount of the above two enzymes is 0.04 kg , enzymatically hydrolyzed at 60°C for 3 hours to obtain the product; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com