Preparation method of high-purity aluminum metaphosphate powder

A high-purity aluminum metaphosphate technology, applied in the field of preparation of high-purity aluminum metaphosphate powder, can solve the problems of difficult separation, complicated operation, and easy pollution of aluminum metaphosphate, and achieve the effect of small equipment investment and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

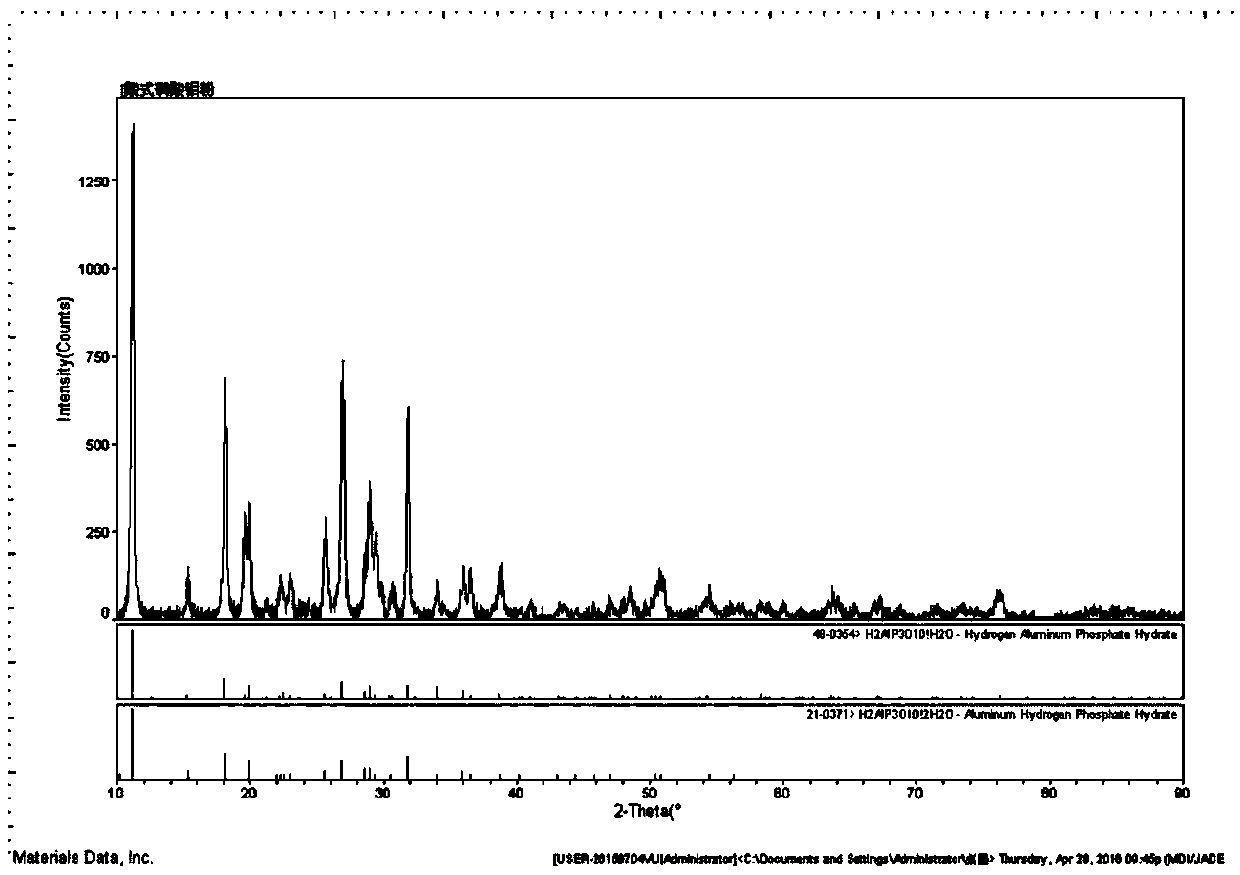

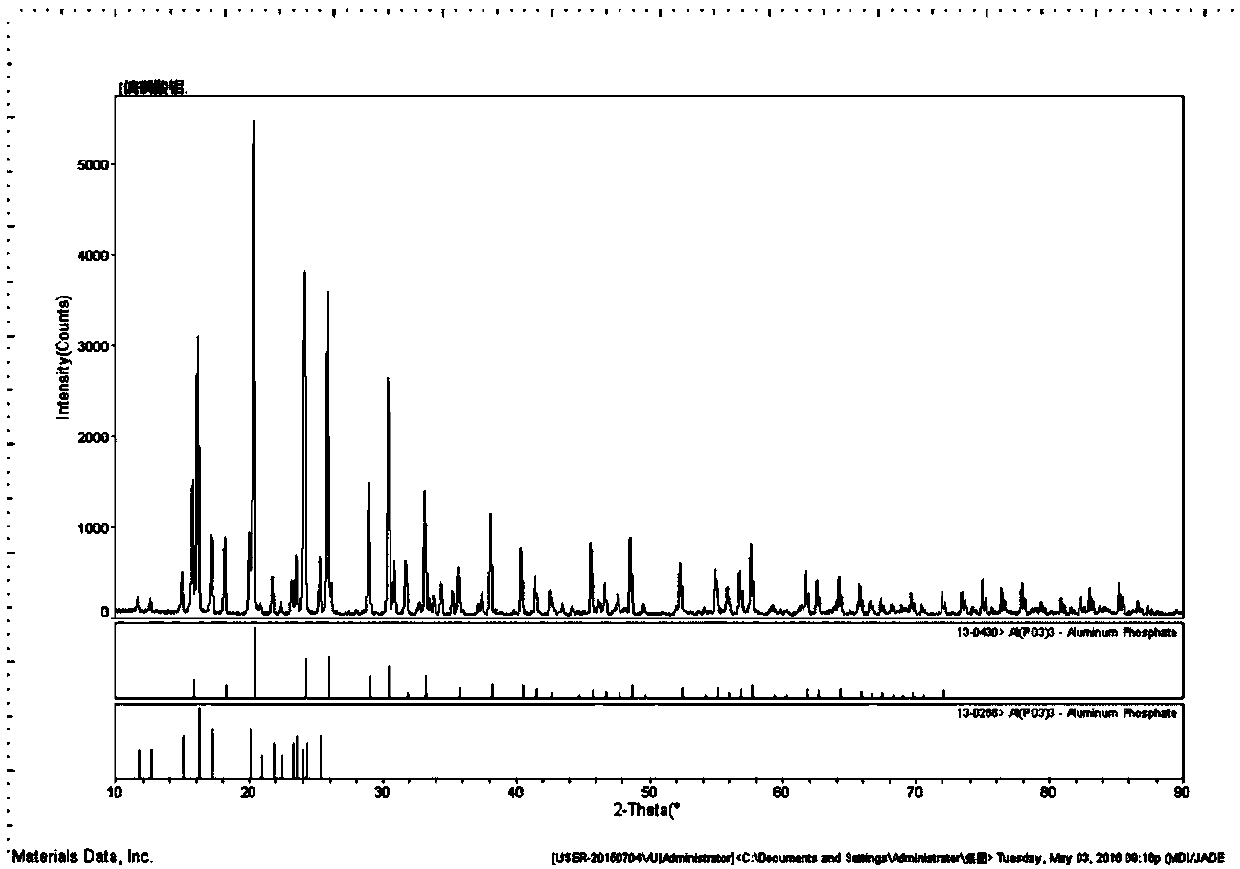

[0029] Add 100kg of electronic-grade phosphoric acid (concentration: 76%) into the reaction kettle, add 20kg of purified water, stir and raise the solution temperature to 50°C, add 26.1kg of high-purity aluminum hydroxide (solid content: 80%), and react for 1 hour to obtain phosphoric acid. Aluminum dihydrogen phosphate solution; place the aluminum dihydrogen phosphate solution in a sintered container lined with polytetrafluoroethylene, heat it to 230°C for dehydration for 6 hours, and convert it into acid aluminum phosphate monohydrate; place the acid aluminum phosphate monohydrate solid in a humidified In the device, hot air at 70°C with a relative humidity of 60% was introduced, weathered for 5 hours, and acid aluminum phosphate monohydrate was converted into powdered aluminum acid phosphate by utilizing the characteristics of water absorption and weathering of acid aluminum phosphate monohydrate; The acid aluminum phosphate powder is roasted at 750°C for 7 hours in a heatin...

Embodiment 2

[0031] Add 100kg of electronic-grade phosphoric acid (concentration 76%) into the reaction kettle, add 40kg of purified water, stir and raise the solution temperature to 100°C, add 24.4kg of high-purity aluminum hydroxide (solid content 80%), and react for 1.2h after the solution is clarified to obtain Aluminum dihydrogen phosphate solution; put the aluminum dihydrogen phosphate solution in a sintered container lined with polytetrafluoroethylene, heat to 240°C for dehydration for 4 hours, and convert it into acid aluminum phosphate monohydrate; put the solid acid aluminum phosphate monohydrate in In the humidifying device, and feed hot air with a relative humidity of 65% at 90°C for weathering for 4 hours, using the characteristics of water absorption and weathering of acid aluminum phosphate monohydrate to convert acid aluminum phosphate monohydrate into acid aluminum phosphate powder; The acid aluminum phosphate powder is roasted at 900°C for 3 hours in a heating furnace to c...

Embodiment 3

[0033] Add 100kg of electronic-grade phosphoric acid (concentration 76%) to the reaction kettle, add 60kg of purified water, stir and raise the solution temperature to 60°C, add 25.2kg of high-purity aluminum hydroxide (solid content 80%), and react for 1.5h after the solution is clarified to obtain Aluminum dihydrogen phosphate solution; put the aluminum dihydrogen phosphate solution in a sintered container lined with polytetrafluoroethylene, heat it to 235 ° C for 2 hours to convert it into acid aluminum phosphate monohydrate; put the solid acid aluminum phosphate monohydrate in In the humidification device, the hot air at 75°C with a relative humidity of 70% is introduced, and weathered for 2 hours. Using the characteristics of water absorption and weathering of acid aluminum phosphate monohydrate, acid aluminum phosphate monohydrate is converted into acid aluminum phosphate powder; The acid aluminum phosphate powder is roasted at 850°C for 5 hours in a heating furnace to co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com