An anti-scaling electroosmosis electrode plate device

An electro-osmosis, electrode plate technology, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve problems such as cathode plate scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, the present invention is further described:

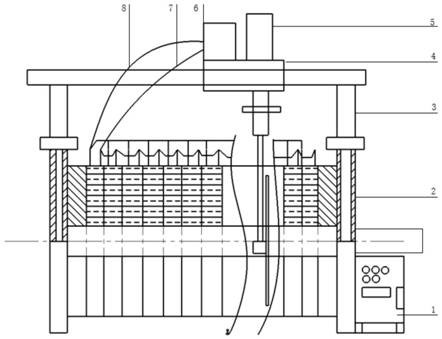

[0014] figure 1 A schematic diagram of an anti-scaling electroosmotic electrode plate device is shown, as shown in the figure, the device includes: control cabinet 1, plate and frame filter press 2, walking frame 3, guide rail 4, friction vibration system 5, power supply 6. Anode plate 7, cathode plate 8. Wherein the friction vibration system 5 is composed of a motor 501 , a transmission shaft 502 , an autorotation head 503 , a friction disc 504 and a folding structure 505 .

[0015] The specific implementation steps are as follows:

[0016] The present invention utilizes the friction between the friction vibration system and the friction vibration of the cathode plate to remove the scale on the cathode plate, that is, as figure 1 During the working process of the electroosmotic plate and frame filter press shown, after each plate is opened and deslimed, the scale of the cat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com