A kind of composite cathode material that reduces self-discharge degree and its preparation method and application

A technology of composite positive electrode material and active positive electrode material, which is applied in the field of composite positive electrode material and preparation, can solve problems such as no improvement, and achieve the effects of reducing generation rate, high consistency, and reducing positive electrode polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

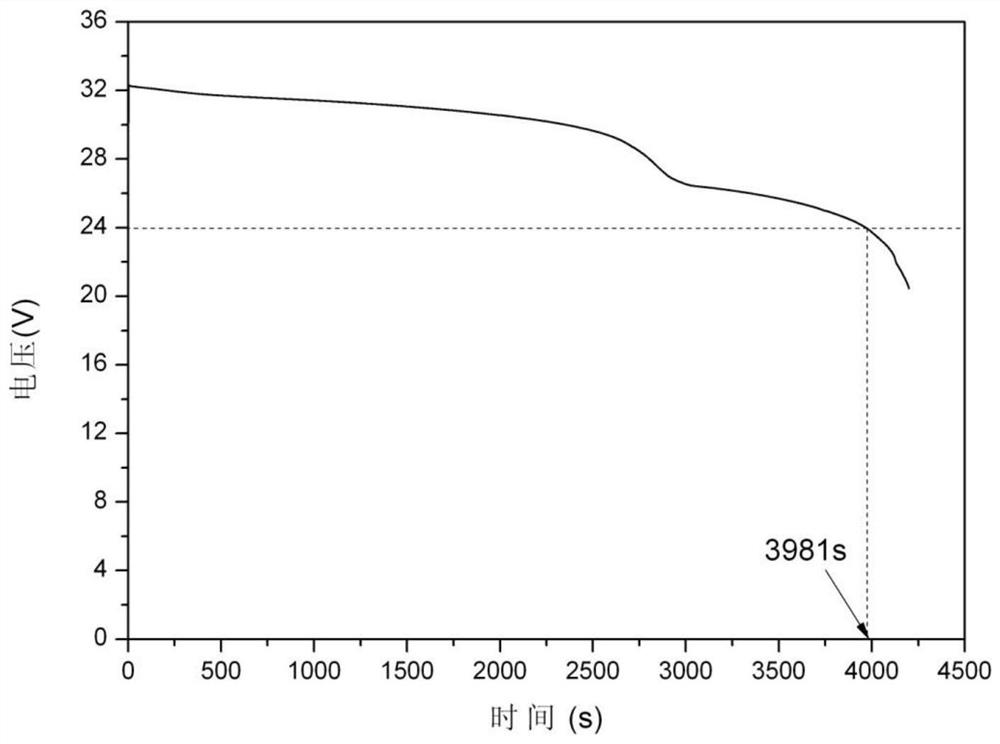

Embodiment 1

[0042] A composite positive electrode material that reduces the degree of self-discharge, which is made of a thermal battery active positive electrode material, a polar thiophilic fixing material, a potassium-containing electrolyte, and a high-conductivity conductive agent, and the mass ratio of the above raw materials is: thermal battery active positive electrode material : Polar thiophilic fixing material: potassium-containing electrolyte: high conductivity conductive agent=60:20:18:2; the polar thiophilic fixing material is Co 9 S 8 .

[0043] Further, the active cathode material of the thermal battery is CoS 2 ; The potassium-containing electrolyte is a multi-element eutectic composed of KCl and LiCl; the high-conductivity conductive agent is acetylene black.

[0044] A method for preparing a composite cathode material with reduced self-discharge, comprising the following steps:

[0045] Step 1. Mixing: Weigh the active positive electrode material of the thermal battery...

Embodiment 2

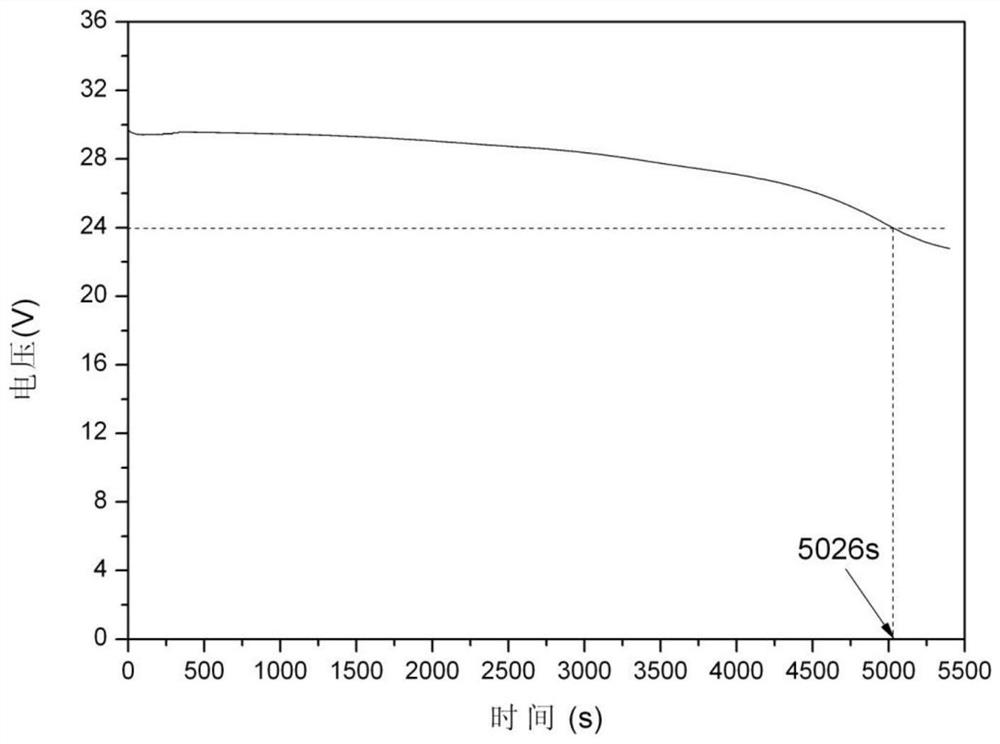

[0050] A composite positive electrode material that reduces the degree of self-discharge, which is made of a thermal battery active positive electrode material, a polar thiophilic fixing material, a potassium-containing electrolyte, and a high-conductivity conductive agent, and the mass ratio of the above raw materials is: thermal battery active positive electrode material : Polar thiophilic fixing material: potassium-containing electrolyte: high conductivity conductive agent=70:10:18:2; the polar thiophilic fixing material is NiCo 2 S 4 .

[0051] Further, the thermal battery active cathode material is CoS 2 ; The potassium-containing electrolyte is a multi-component eutectic composed of KF and LiCl-LiBr molten salt; the high-conductivity conductive agent is carbon nanotubes.

[0052] A method for preparing a composite cathode material with reduced self-discharge, comprising the following steps:

[0053] Step 1. Mixing: Weigh the active positive electrode material of the t...

Embodiment 3

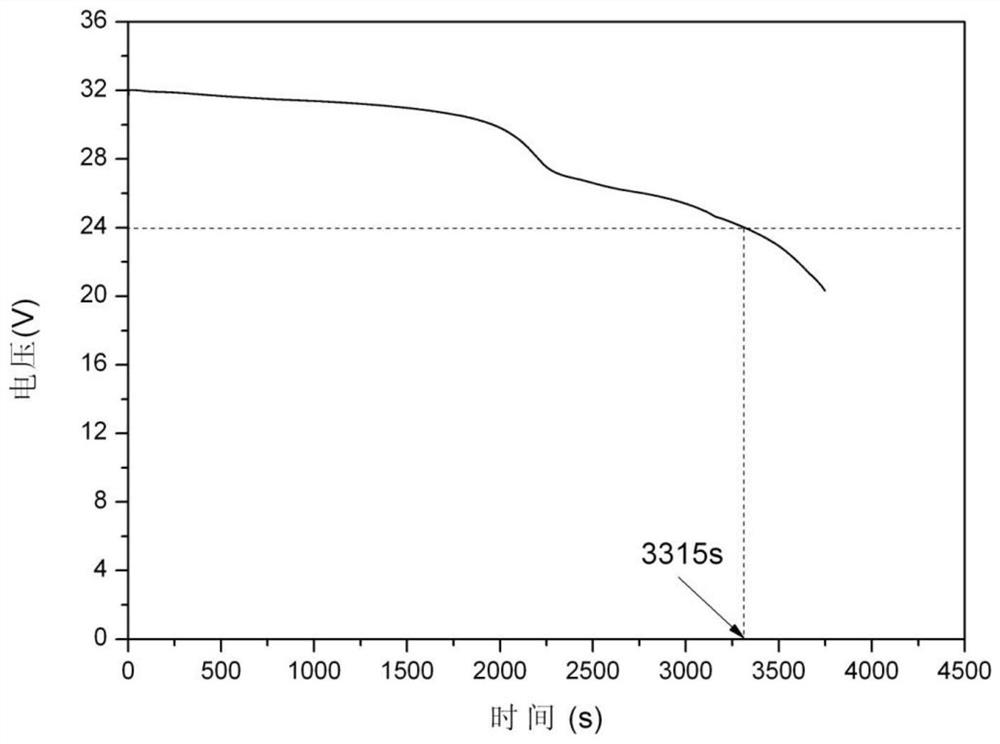

[0058] A composite positive electrode material that reduces the degree of self-discharge, which is made of a thermal battery active positive electrode material, a polar thiophilic fixing material, a potassium-containing electrolyte, and a high-conductivity conductive agent, and the mass ratio of the above raw materials is: thermal battery active positive electrode material : Polar thiophilic fixing material: potassium-containing electrolyte: high conductivity conductive agent=50:2:10:0.1; the polar thiophilic fixing material is Ni 2 CoS 4 .

[0059] Further, the active cathode material of the thermal battery is FeS 2 、NiS 2 、MoS 2 ; The potassium-containing electrolyte is a multi-element eutectic composed of KCl, KBr and LiCl-LiF molten salt; the high-conductivity conductive agent is acetylene black and graphene.

[0060]A method for preparing a composite cathode material with reduced self-discharge, comprising the following steps:

[0061] Step 1. Mixing: Weigh the therm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com