Super capacitor based on cobalt-based material

A supercapacitor, cobalt-based technology, used in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, can solve the problems of high cost, complex process, and expensive graphene, and achieve improved conductivity, excellent cycle performance, Simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] 1G CoCl 2 · 6h 2 O and 1.02G NA 2 MOO 4 The obtained homogeneous solution was transferred to the inner lined stainless steel high pressure reactor, and a clean foam is placed in a reactor in an oven in an oven at 120 ° C. Cobalt molybdate COMOO 4 Electrode material.

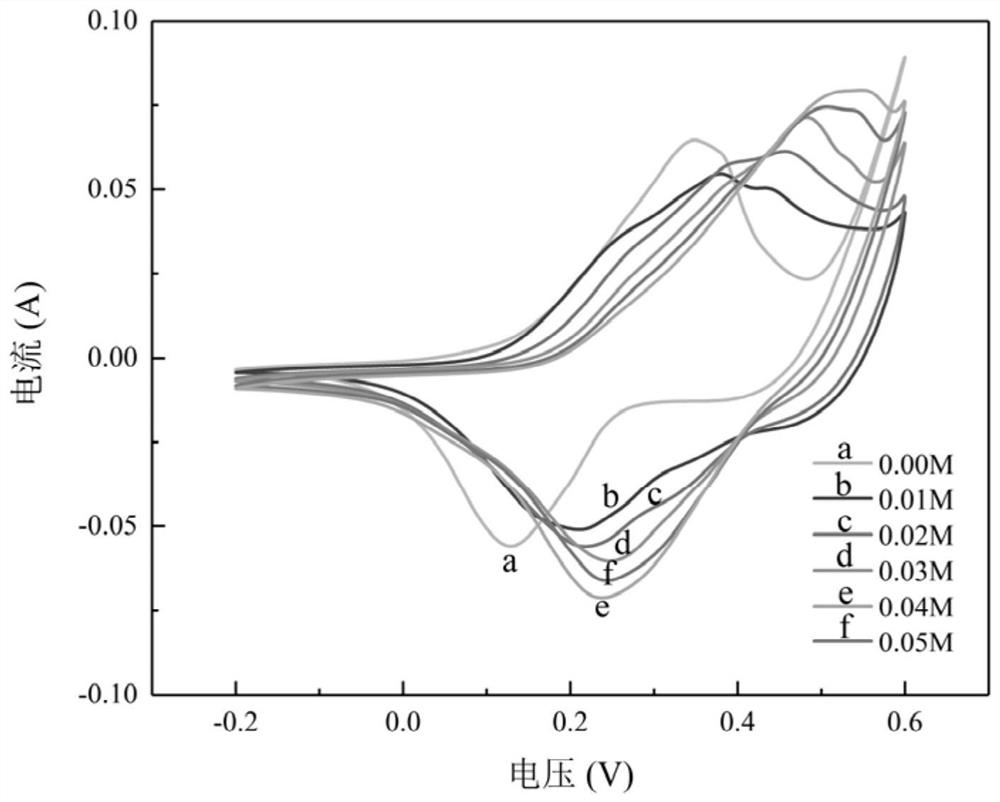

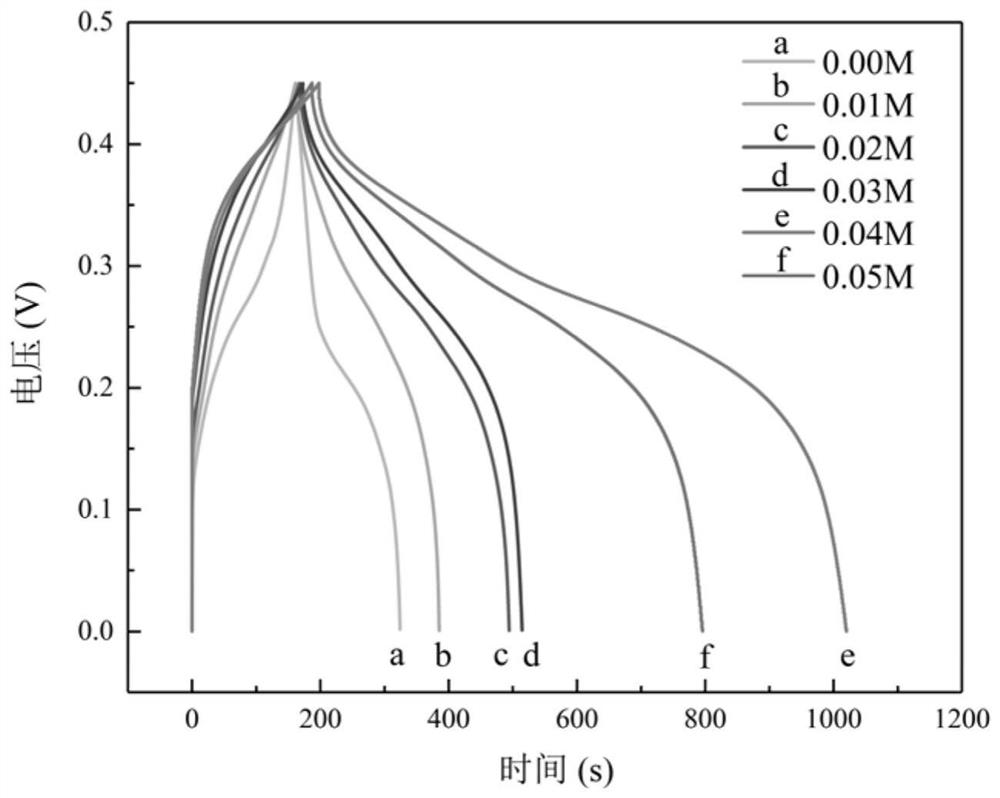

[0059] The standard three-electrode system is used, the PT electrode is used for electrodes, saturated glycine electrodes to reference electrodes, cobalt molybdate cobalt COMOO 4 The electrode material is a working electrode, and the addition of 0.01 mol / L, 0.02 mol / L, 0.03 mol / L, 0.04mol / L, and 0.05mol / L of K in the KOH electrolyte of 2 mol / L. 3 Fe (CN) 6 Circulating voltammetry (potential window is -0.2V to 0.6V, scan rate is 20mv S -1 ) And constant current charge and discharge curve (current density is 1A g -1 ) figure 1 with figure 2 .

[0060] From figure 2 It can be seen that add 0.04mol / L K 3 Fe (CN) 6 The specific capacitor is up to 1778F G -1 Never add K 3 Fe (CN) 6 Comparison capacitan...

Embodiment 2

[0062] Cocl of 1.05mmol 2 · 6h 2 O and 0.7mmol NA 3 V 4 O 8 The obtained homogeneous solution was dissolved in 50 ml of deionized water, and then the obtained homogeneous solution was transferred to the inner liner high-pressure reactor, and a clean foam nickel was put into the reactor, and the reaction kettle was placed in an oven at 130 ° C in an oven reaction for 3h. Cobalt Cobalt Co 3 V 2 O 8 Electrode material.

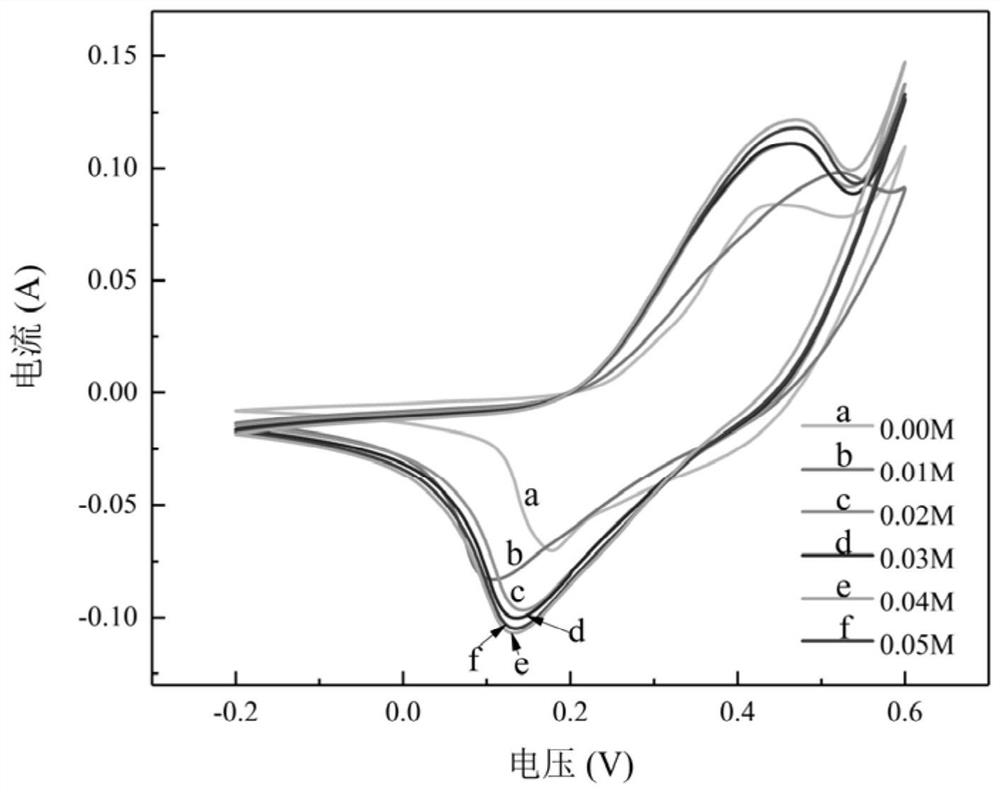

[0063] The standard three-electrode system is used, and the PT electrode is used for electrodes, saturated glycine electrodes for reference electrodes, cobalt vanadate CO 3 V 2 O 8 The electrode material is a working electrode, and the addition of 0.01 mol / L, 0.02 mol / L, 0.03 mol / L, 0.04mol / L, and 0.05mol / L of K in the KOH electrolyte of 2 mol / L. 3 Fe (CN) 6 Circulating voltammetry (potential window is -0.2V to 0.6V, scan rate is 20mv S -1 ) And constant current charge and discharge curve (current density is 1A g -1 ) image 3 with Figure 4 .

[0064] From...

Embodiment 3

[0066] 1g CoCl 2 · 6h 2 O Soluble in 20 ml of deionized water, placed on a magnetic stirrer, continuously stirred for 30 minutes to form a homogeneous solution. Will 0.3G NABH 4 And 0.06 g of NaOH was dissolved in 20 mL of deionized water, and then drip droplets were added dropwise to the above mixed solution, and a clean foam nickel was placed thereto, and then stirred for 3 hours to obtain a boron Cobalt COB electrode material.

[0067] The standard three-electrode system is used, the PT electrode is the counter electrode, the saturated glycine electrode is the reference electrode, the boride COB electrode material is a working electrode, and 0.01 mol / l, 0.02 mol, respectively, at 2 mol / L of KOH electrolyte, respectively. / L, 0.03mol / L, 0.04mol / L and 0.05mol / L of K 3 Fe (CN) 6 The circulating voltammetry (potential window is (-0.2V to 0.6V, the scan rate is 20mv s) -1 ) And constant current charge and discharge curve (current density is 1A g -1 ) Figure 5 with Image 6 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com