A wind power generator main shaft provided with a protective layer and its protective layer attachment process

A technology for wind power generators and protective layers, applied to shafts, shafts and bearings, mechanical equipment, etc., can solve problems such as difficult to control uniformity, complicated painting process, and difficult to spray evenly, achieving remarkable thermal stability and simple processing technology , good anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

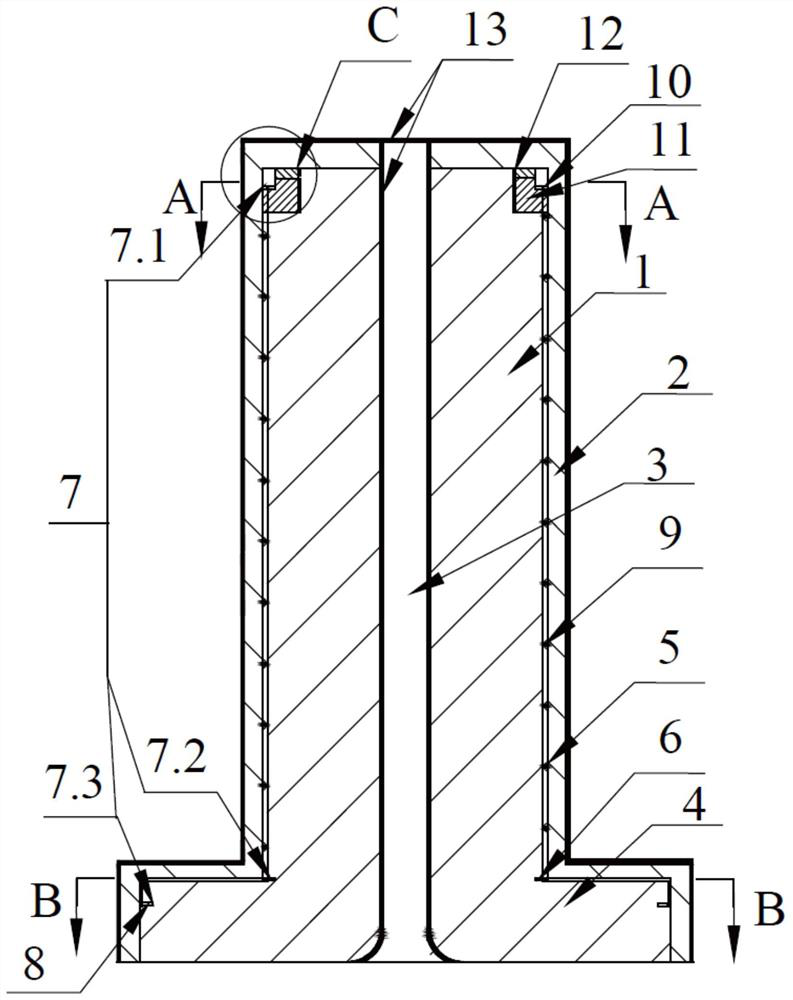

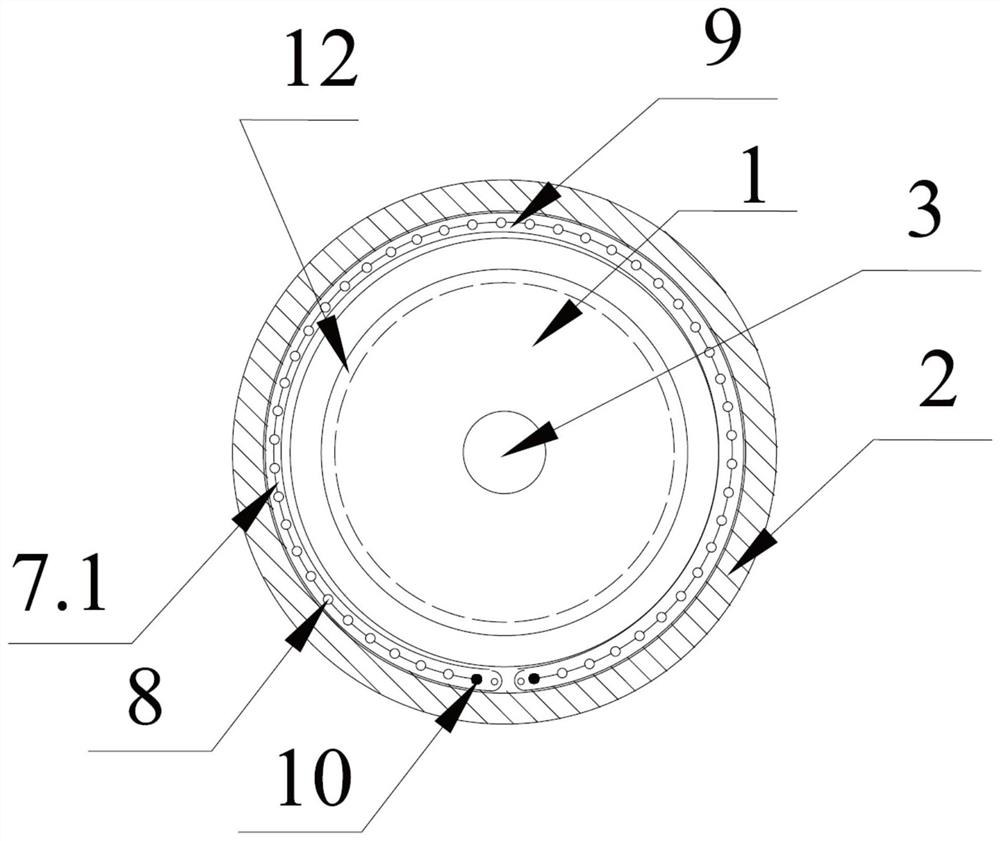

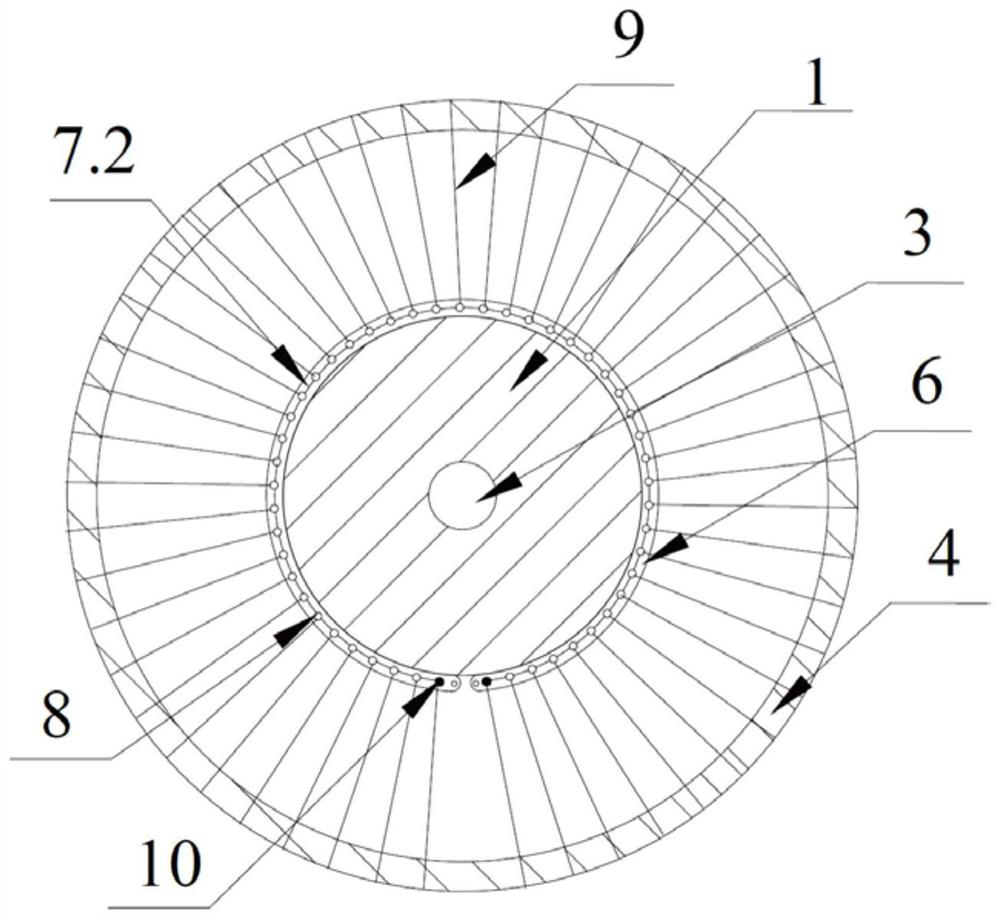

[0038] Such as Figure 1~5 As shown, the present invention is a wind-driven generator main shaft provided with a protective layer, a Teflon surface layer 13 is attached to the surface of the wind-driven generator main shaft, and a reinforcement layer is arranged in the middle of the generator main shaft, and the reinforcement layer is carbon fiber Silk or carbon fiber membrane.

[0039] In order to facilitate the firm combination between Teflon and the surface of the wind power main shaft, and make its attachment process simple and easy to automate, the preferred embodiment of the present invention is that the Teflon surface layer 13 is sprayed on the gene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com