Method for manufacturing lithium secondary battery with improved high-temperature storage properties

A lithium secondary battery, battery technology, applied in the direction of secondary battery, secondary battery manufacturing, secondary battery repair/maintenance, etc. Effects of suppressing oxidation side reactions, improving high-temperature storage safety and cycle life characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

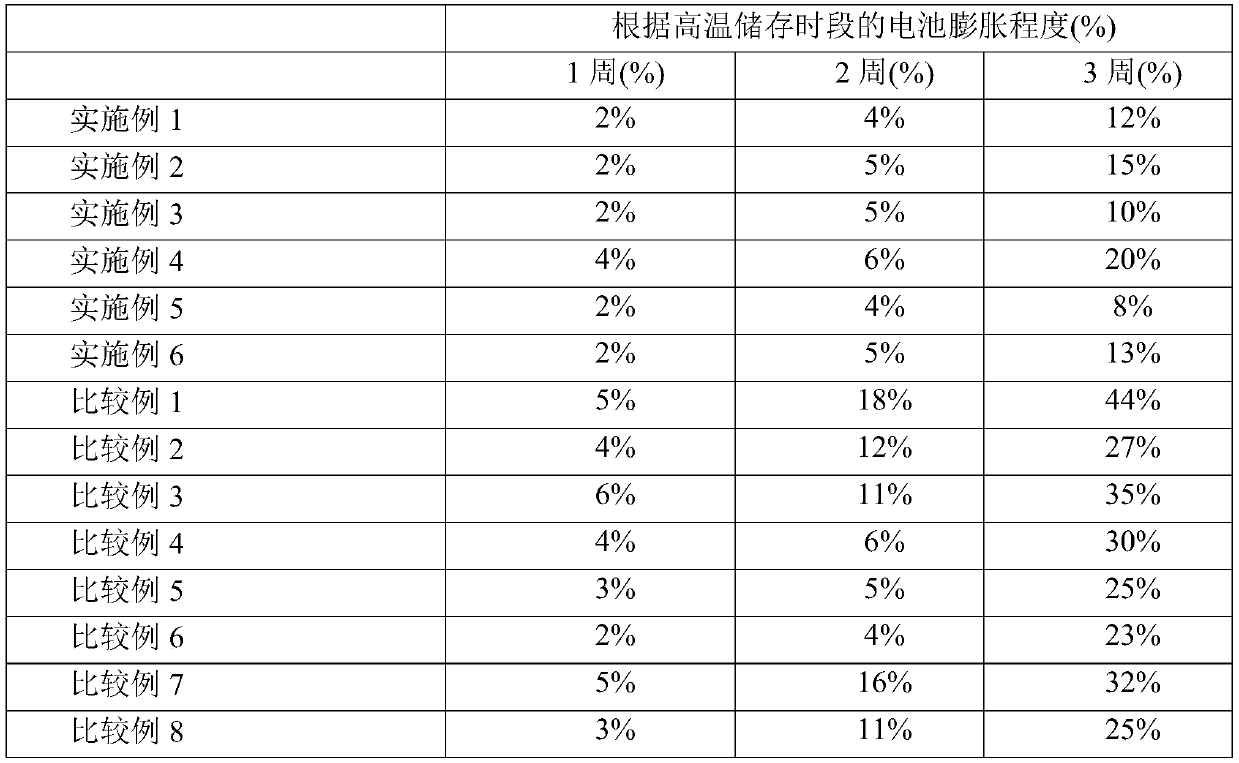

Examples

Embodiment 1

[0100] (Preparation of non-aqueous electrolyte)

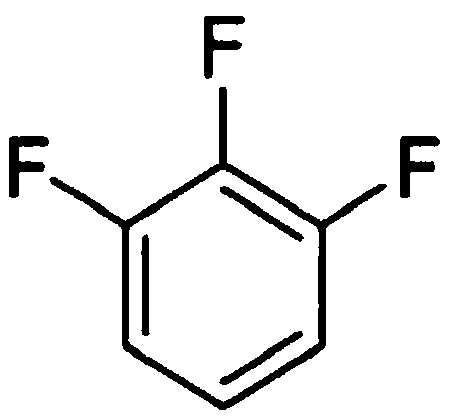

[0101] A nonaqueous electrolyte was prepared by adding 5 g of 1,2,3-trifluorobenzene, 1 g of vinylene carbonate (VC), and 3 g of 1,3-propane sultone to 91 g of a mixed solvent prepared by 1.0M LiPF 6 Prepared by mixing with an organic solvent having a composition of ethylene carbonate (EC):propylene carbonate (PC):propyl propionate (PP)=3:1:6 (weight ratio).

[0102] (production of positive electrode)

[0103]Based on 100 parts by weight of N-methyl-2-pyrrolidone (NMP) as a solvent, add 70 parts by weight of solids to prepare positive electrode active material slurry, which is positive electrode active material (lithium cobalt oxide ( LiCoO 2 )): conductive material (bundle-type carbon nanotube (manufactured by LG Chem., number: B.CNT): binder (polyvinylidene fluoride (PVDF)) mixed at a weight ratio of 97.7:0.3:2 The positive electrode active material slurry was applied to a positive electrode current collector (Al thin fil...

Embodiment 2

[0110] A non-aqueous electrolyte and a lithium secondary battery including the non-aqueous electrolyte were manufactured in the same manner as in Example 1, except that: in the preparation of the non-aqueous electrolyte in Example 1, 95 g of the mixed solvent included 1 g of 1,2,3-trifluorobenzene.

Embodiment 3

[0112] A lithium secondary battery including the non-aqueous electrolyte was manufactured in the same manner as in Example 1, except that when manufacturing the secondary battery of Example 1, at 5 kgf / cm 2 The formation process is carried out under pressure conditions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| loose density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com