Modified organic acid and preparation method thereof

An organic acid and modification technology, applied in the field of medicine, can solve the problems of skin corrosion, organic solvents are harmful to the human body, and organic acids are easy to precipitate, and achieve the effect of enhancing stability and solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) Dissolve 0.2g and 2g of PEG-400 and α-cyclodextrin into 20 mL of deionized water to obtain a mixed solution;

[0033] 2) Put the mixed solution at room temperature and stir for 2 days, then stand for one day, filter, and dry at 100°C for 3 hours to obtain a solid;

[0034] 3) Thoroughly mix and grind the solid and salicylic acid with masses of 1g and 0.05g to obtain a mixture;

[0035] 4) Put the mixture in an open pressure bottle without applying extra pressure. Heat to 150°C and keep for 3h to obtain modified salicylic acid with a purity of 99% and a melting point of 173°C.

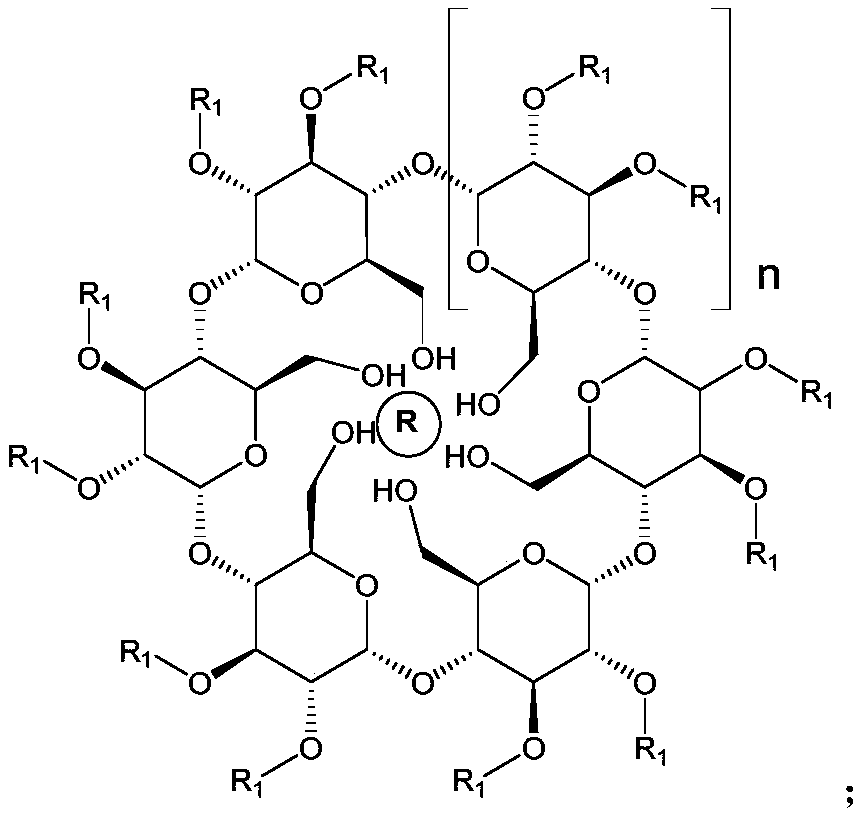

[0036] In the above-mentioned modified organic acid, the organic acid is bonded to the central cavity of the cyclodextrin by hydrogen bonding. The structural formula of the modified organic acid is as follows:

[0037]

[0038] Wherein: R is salicylic acid; n is 1; R1 is hydrogen.

Embodiment 2

[0040] 1) Dissolve 1g of both PEG-800 and β-cyclodextrin into 20mL of deionized water to obtain a mixed solution;

[0041] 2) Put the mixed solution at room temperature and stir for 2 days, then stand for one day, filter, and dry at 100°C for 3 hours to obtain a solid;

[0042] 3) Thoroughly mix and grind the solid and salicylic acid with masses of 1g and 0.2g to obtain a mixture;

[0043] 4) Place the mixture in a sealed pressure bottle. It is heated to 150°C and the absolute pressure is maintained at 1.5 bar. Keep it for 3h to obtain modified salicylic acid with a purity of 99% and a melting point of 171.5°C.

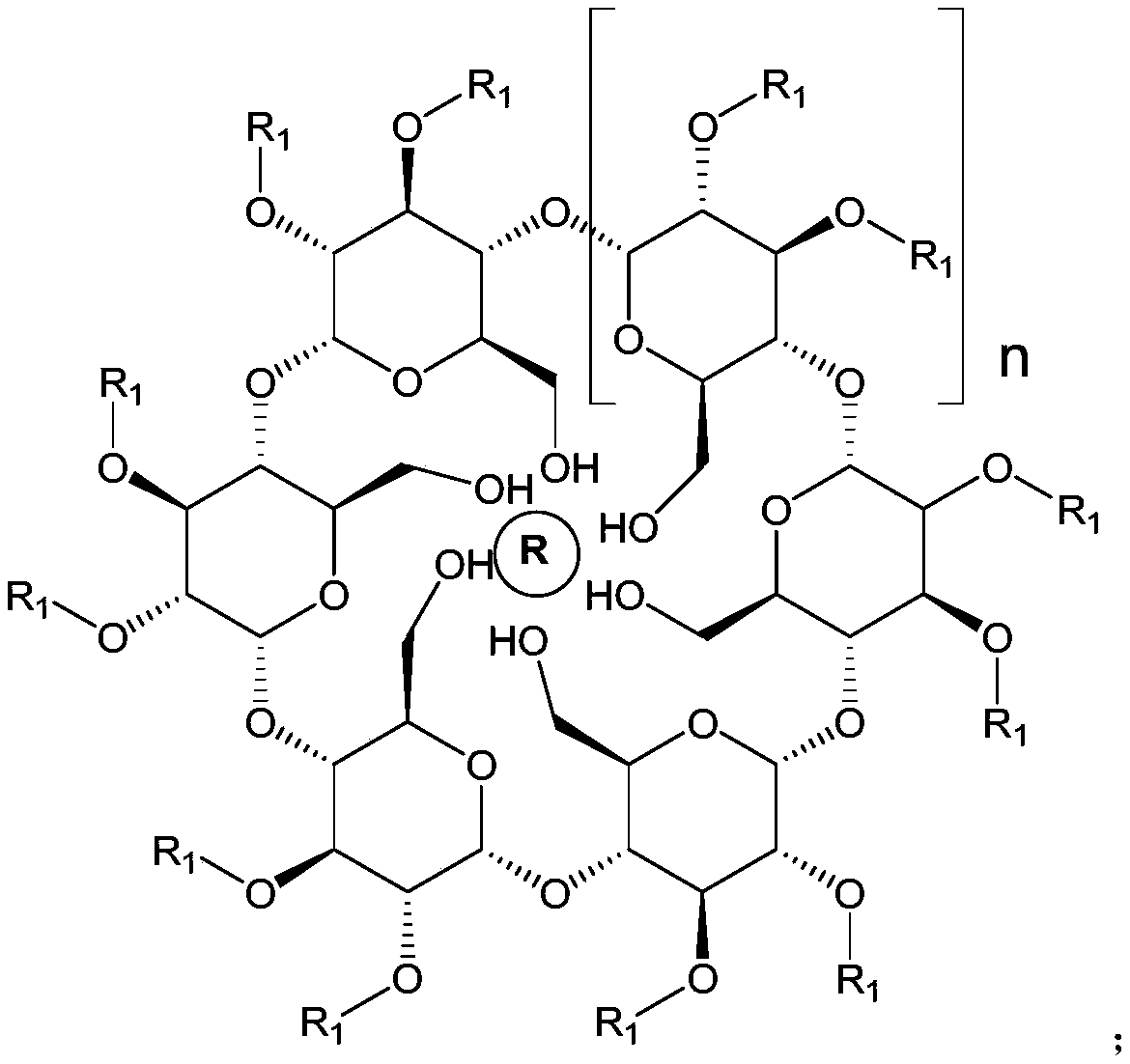

[0044] In the above-mentioned modified organic acid, the organic acid is bonded to the central cavity of the cyclodextrin by hydrogen bonding. The structural formula of the modified organic acid is as follows:

[0045]

[0046] Wherein: R is salicylic acid; n can be 2; R1 is hydrogen.

Embodiment 3

[0048] 1) Dissolve 2g and 1g of PEG-1000 and γ-cyclodextrin into 20 mL of deionized water respectively to obtain a mixed solution;

[0049] 2) Put the mixed solution at room temperature and stir for 2 days, then stand for one day, filter, and dry at 100°C for 3 hours to obtain a solid;

[0050] 3) Thoroughly mix and grind the solid and azelaic acid with a mass of 1 g and 0.4 g to obtain a mixture;

[0051] 4) Place the mixture in a sealed pressure bottle. Heat to 150°C and keep the absolute pressure at 1.6 bar. Keep it for 3h to obtain modified azelaic acid with a purity of 99% and a melting point of 165°C.

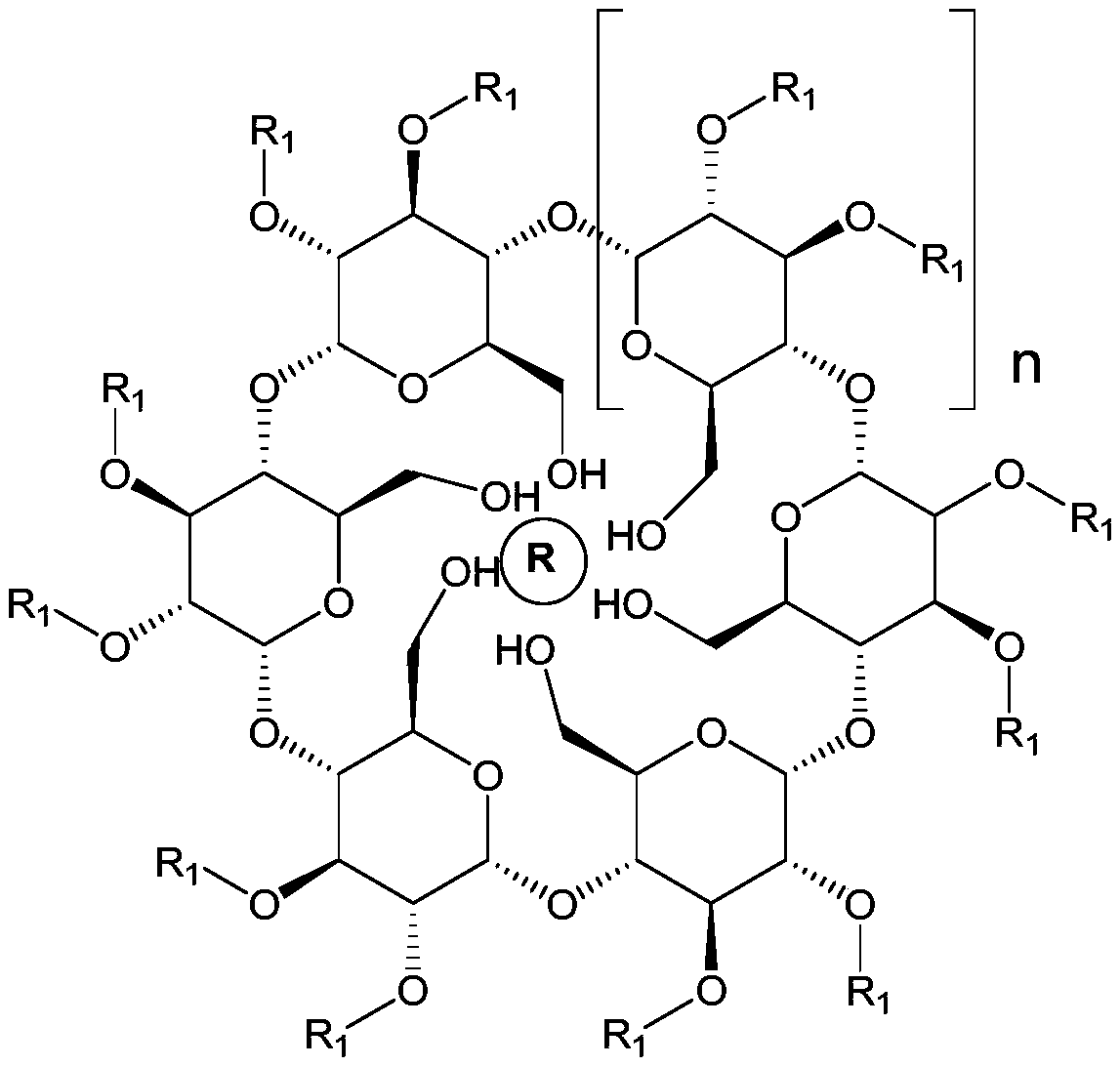

[0052] In the above-mentioned modified organic acid, the organic acid is bonded to the central cavity of the cyclodextrin by hydrogen bonding. The structural formula of the modified organic acid is as follows:

[0053]

[0054] Wherein: R is azelaic acid; n is 3; R1 is hydrogen.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com