Injectable hydrogel and preparation method thereof

A technology for injecting water and gel, applied in pharmaceutical formulations, surgery, drug delivery, etc., can solve problems such as poor mechanical properties and low cross-linking strength of hydrogels, and achieve good fluidity, ideal cross-linking strength, and preparation process. Safety and environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0050] As mentioned earlier, there are always some problems in one way or another in existing multi-component hydrogels used as injectable hydrogels, and some need to use a large amount of toxic organic solvents when preparing their cross-linked substrates. The environment is very harmful, and its natural antibacterial and antiseptic properties are poor, so it cannot be used as an injectable hydrogel; some have low cross-linking strength and poor mechanical properties, which are greatly restricted in application. In view of this, the present inventors conducted extensive research on injectable hydrogels.

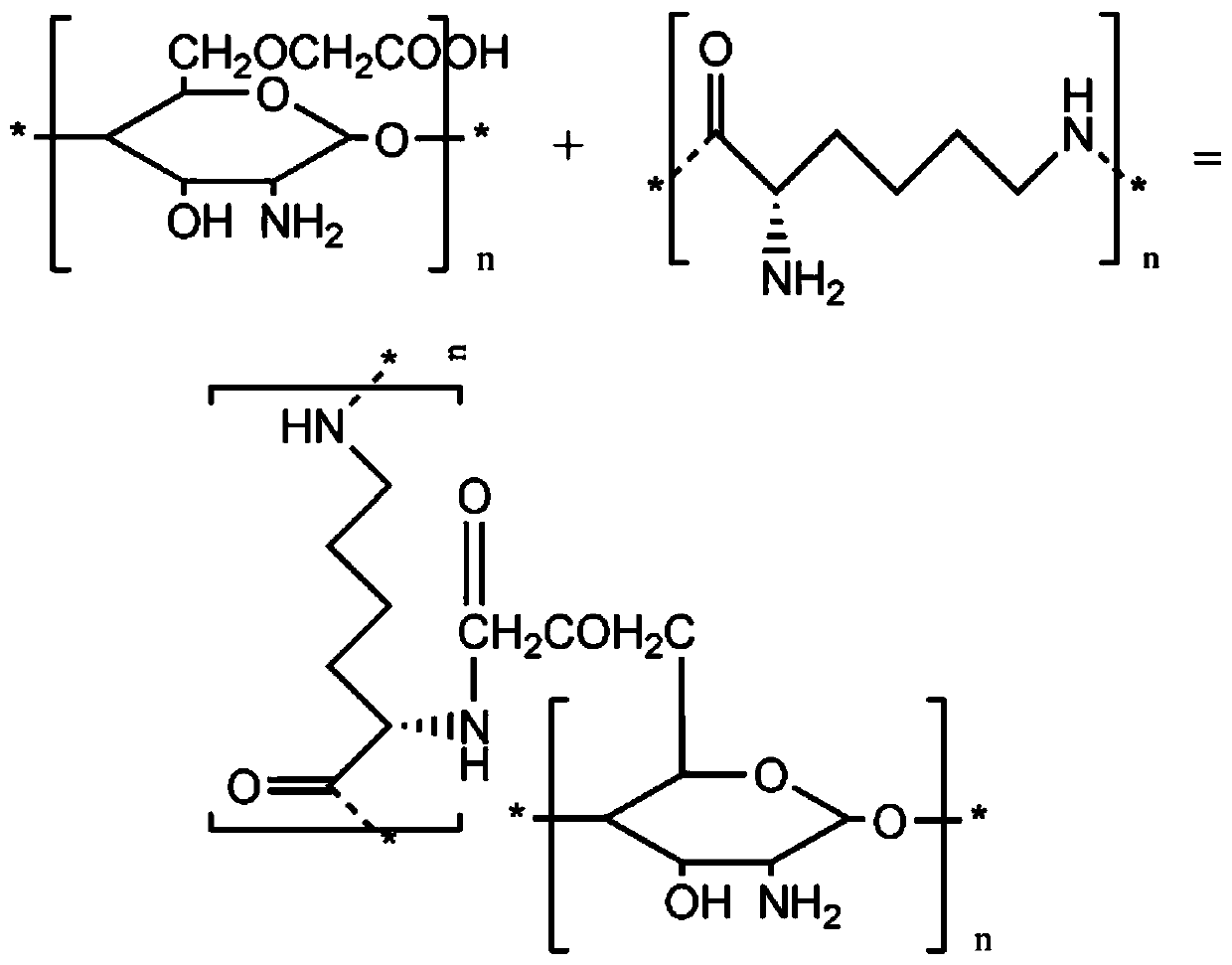

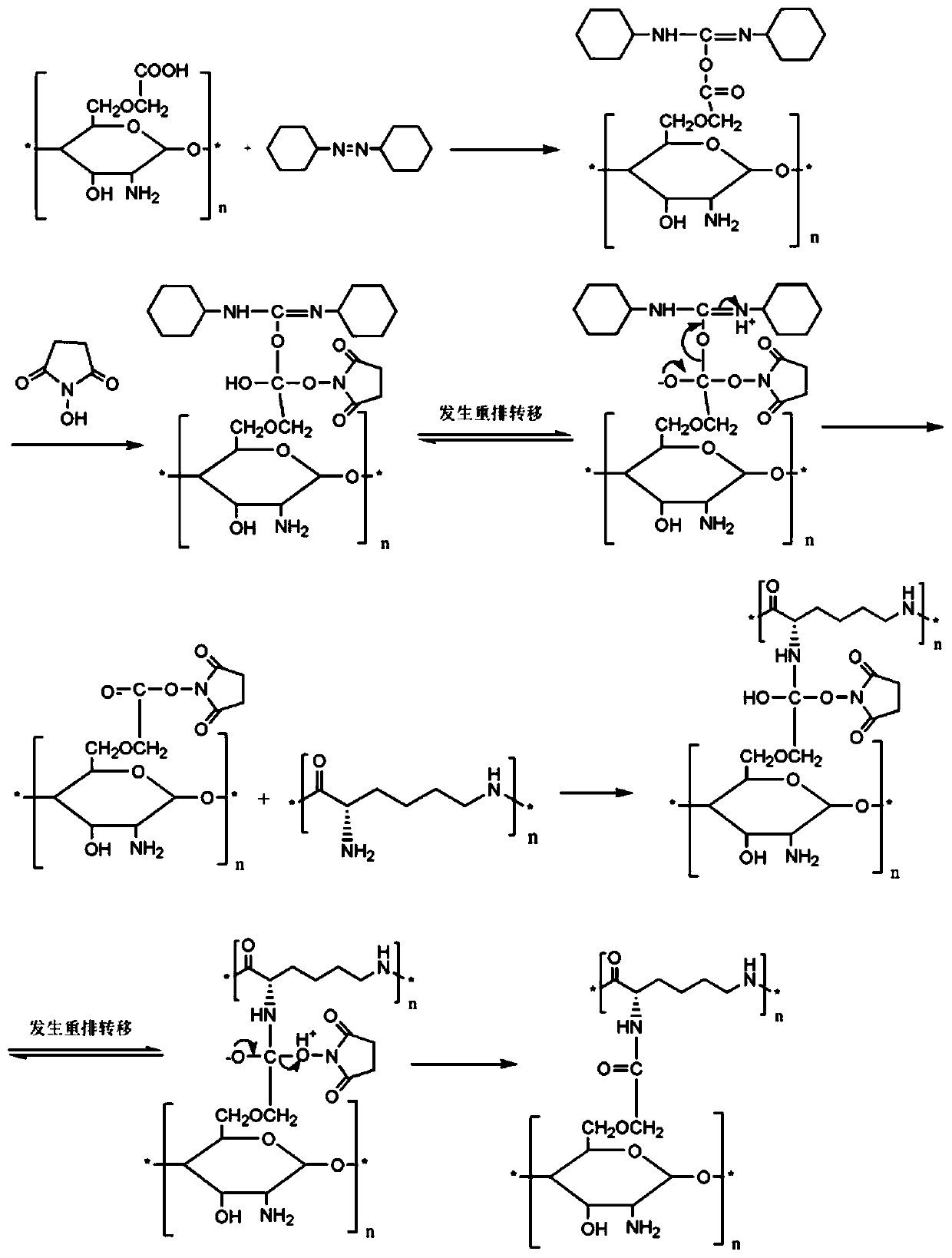

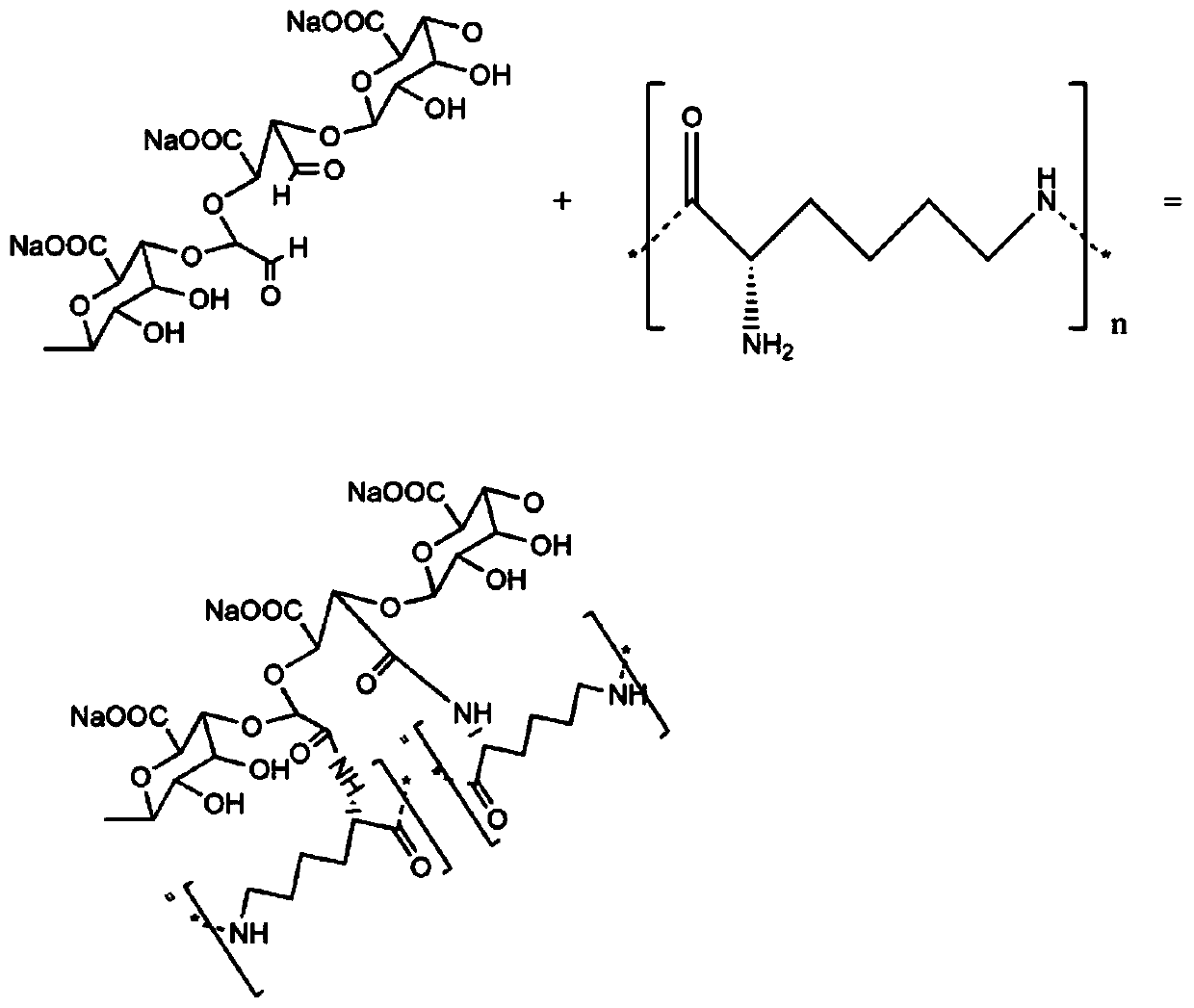

[0051] The inventors have found that the injectable hydrogel is prepared by using modified polysaccharides such as polylysine and carboxymethyl chitosan or alginylated sodium alginate as cross-linked substrates, less use of organic chemical reagents, The preparation process is safe and environment-friendly; the prepared injectable hydrogel is non-toxic and has ideal cross-li...

Embodiment 1

[0093] Add 8.00 g of polylysine to a 100 mL beaker, and then add 92 mL of deionized water to adjust the pH value to 7 to obtain a polylysine solution. Add 8.00g carboxymethyl chitosan in another 100mL beaker, add deionized water 92mL, obtain carboxymethyl chitosan solution. After the two component solutions are completely dissolved, add 0.7g EDC (carbodiimide) to the prepared carboxymethyl chitosan solution, and add 0.7g NHS (N-hydroxysuccinimide) to the prepared polylysine solution. amine), were stirred for 2h. It was sterilized at 121° C. for 30 minutes. After the sterilization, the two activated dispersions were mixed in equal volumes, and no hydrogel was formed.

Embodiment 2

[0095] Add 4.00 g of polylysine to a 100 mL beaker, and then add 96 mL of deionized water to adjust the pH to 9 to obtain a polylysine solution. Add 8.00g carboxymethyl chitosan in another 100mL beaker, add deionized water 92mL, obtain carboxymethyl chitosan solution. After the two component solutions are completely dissolved, add 0.7g EDC (carbodiimide) to the prepared carboxymethyl chitosan solution, and add 0.7g NHS (N-hydroxysuccinimide) to the prepared polylysine solution. amine), were stirred for 2h. It was sterilized at 121° C. for 30 minutes. After the sterilization, the two activated dispersions were mixed in equal volumes, and no hydrogel was formed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com