Guanidyl macromolecule antibacterial nano microspheres and preparation method thereof

A nano-microsphere and macromolecule technology, applied in the preparation of microspheres, microcapsule preparations, etc., can solve the problems that the antibacterial masterbatch is not suitable for extrusion, the wall is adhered to the screw, the material performance is degraded, etc., and the preparation process is safe and environmentally friendly. Good bactericidal effect, less harm to human body and environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

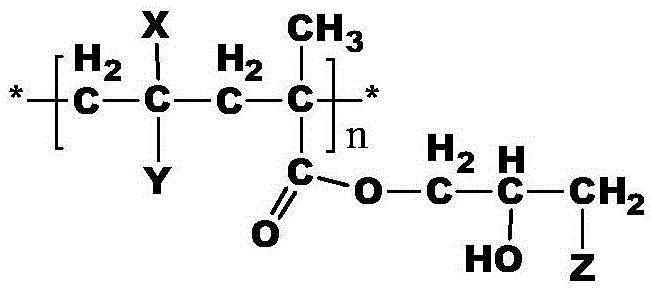

[0052] 1. prepare PSGMA polymer nanoparticle, comprise the steps:

[0053] Add 4.0 g of styrene to 130 mL of deionized water, stir, blow nitrogen to exhaust oxygen, heat to 75°C, and then add 10 mL of aqueous solution containing 0.1 g of potassium persulfate. After two hours of reaction, GMA3.0g was added, and the reaction was continued for 21h to stop the reaction. Aqueous sodium bicarbonate solution was added dropwise to adjust the pH to neutral. After centrifugation, washing, and drying in an oven at 50° C., a white powdery solid is obtained, which is PSGMA polymer nanoparticles.

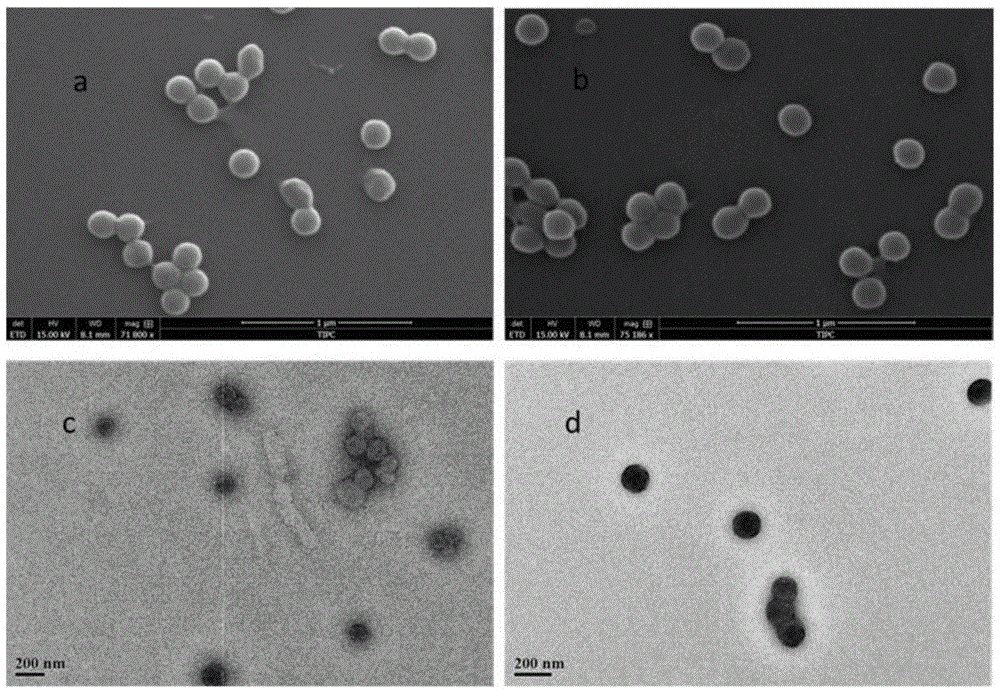

[0054] 2. Characterization of PSGMA polymer nanoparticles

[0055] 1) The average particle diameter of the nanospheres in the PSGMA emulsion measured by dynamic light scattering method is 113.2nm.

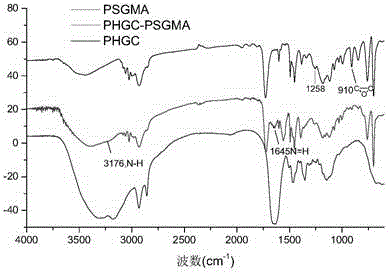

[0056] 2) The prepared PSGMA polymer nanoparticles were characterized by Fourier transform infrared spectroscopy, the results are as follows: due to the characteristic peak of the epoxy bond at 125...

Embodiment 2

[0058] The preparation of PEMAGMA polymer nanoparticles comprises the following steps:

[0059] Add 4.0 g of ethyl methacrylate into 130 mL of deionized water, stir, blow nitrogen to exhaust oxygen, heat to 80°C, and add 10 mL of aqueous solution containing 0.1 g of potassium persulfate. After two hours of reaction, 3.0 g of GMA was added, and the reaction was continued for 18 hours to stop the reaction. Aqueous sodium bicarbonate solution was added dropwise to adjust the pH to neutral. After centrifugation, washing, and drying in an oven at 50°C, a white powdery solid is obtained, which is PEMAGMA polymer nanoparticles.

Embodiment 3

[0061] 1. Prepare PHGC-PSGMA nano antibacterial particles, comprising the following steps:

[0062] Add 1.0 g of the PSGMA polymer prepared in Example 1 into 5.0 g of deionized water, ultrasonically disperse, then add 1.0 g of polyhexamethylene monoguanidine hydrochloride (PHGC), stir, and heat to 60 ° C, 0.002 g of triethylamine catalyst was added, and the reaction was stopped after 48 hours. After centrifugal separation and washing for 5 times, drying in an oven at 50° C. to obtain a white powdery solid, which is PHGC-PSGMA nanometer antibacterial particles.

[0063] 2. Characterization of PHGC-PSGMA nano antibacterial particles and detection of antibacterial performance

[0064] PHGC was prepared as a solution, and PHGC-PSGMA was ultrasonically dispersed in water to obtain an emulsion.

[0065] 1) Utilize the dynamic light scattering method to record the average particle diameter of the nano-microspheres in the PHGC-PSGMA emulsion to be 172.9nm, while the average particle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com