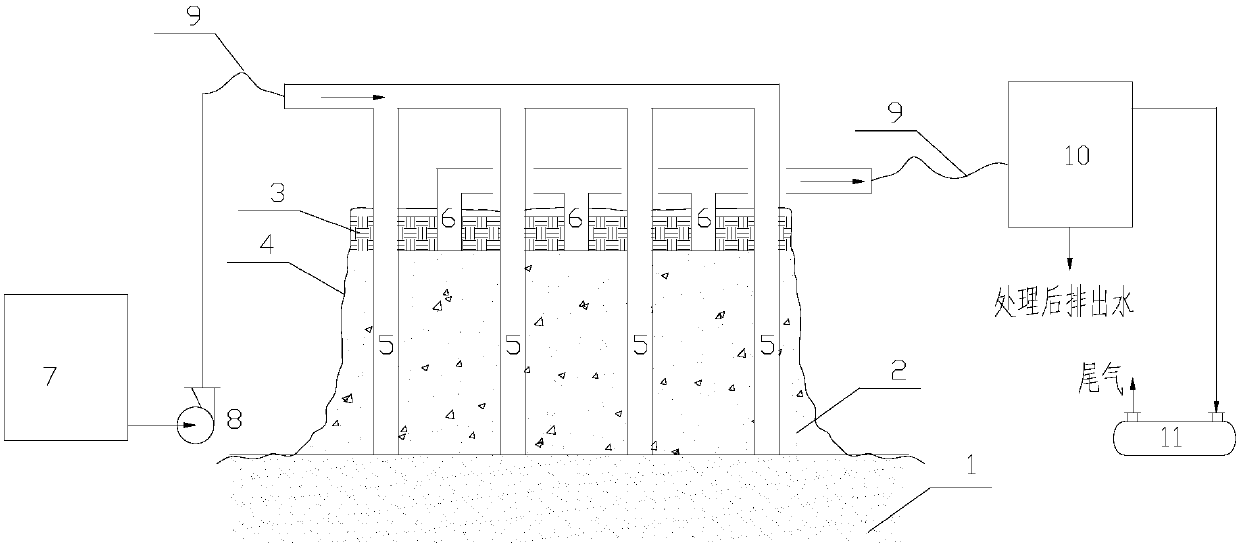

Method for treating heavy metal pollution in soil by using a low-position leaching high-position extraction technology

A technical treatment and leaching technology, which is applied in the field of heavy metal pollution in soil by low-level leaching and high-level extraction technology, can solve the problems of easy flow into the groundwater environment, long repair period, and high energy consumption, so as to prevent heavy metal salts from polluting groundwater and Soil, high-efficiency, ecological and environmental protection, sufficient effect of leaching treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The heavy metal content of the sampled soil sample is Pb: 78mg / kg, Cd: 0.2mg / kg, Cr: 96mg / kg, Cu: 60mg / kg, Zn: 1270mg / kg,

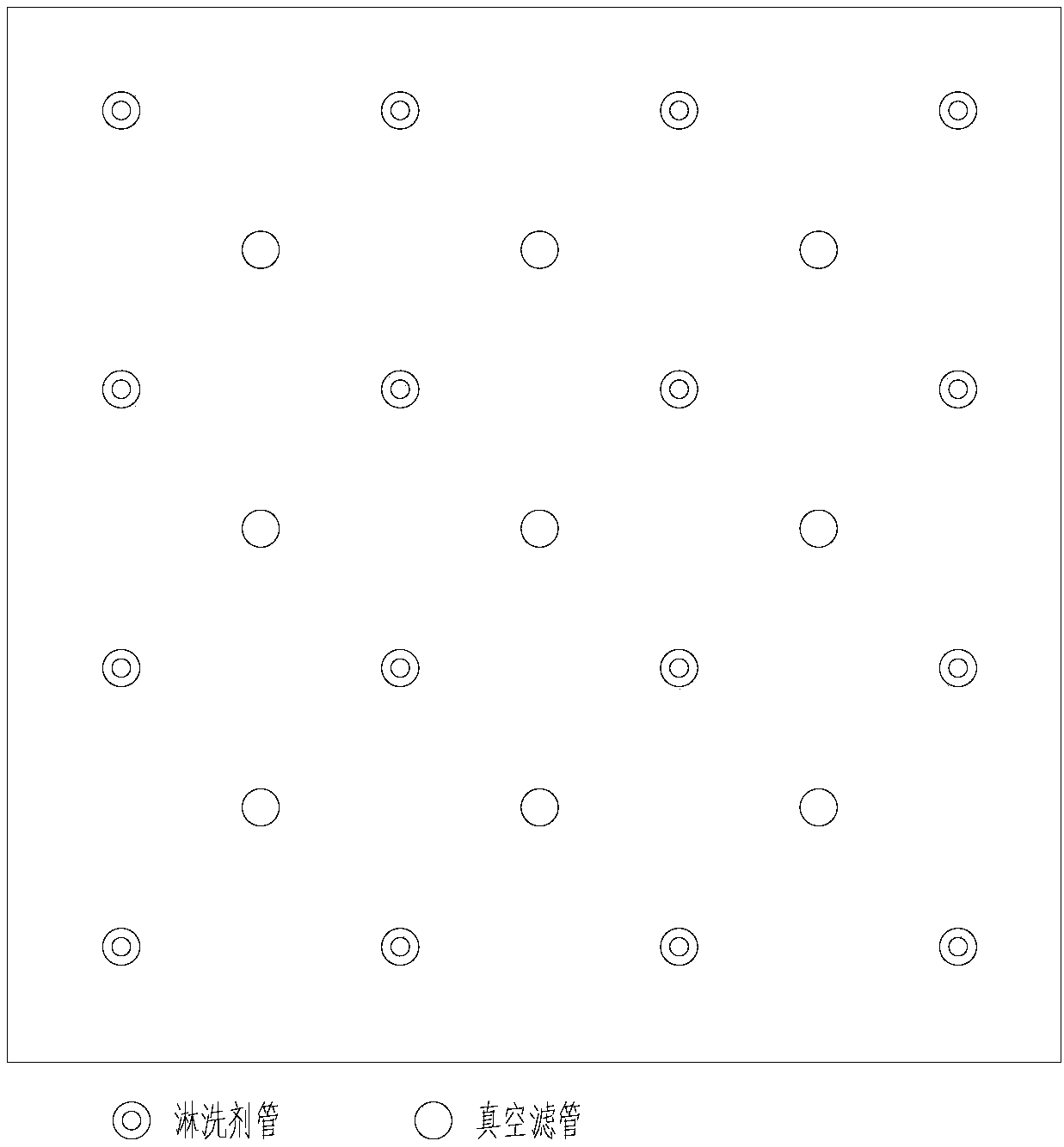

[0056] Step 1. On the planting land of 3m*3m*0.4m, drill bagged sand wells with a diameter of 7cm and a depth of 40cm. The spacing between the wells is 1.3m, and the arrangement of the sand wells is a square distribution of 9;

[0057] Step 2, laying a deep silty clay working cushion on the surface, and the thickness of the working cushion is 5cm;

[0058] Step 3, a PVC eluent pipe diameter of 6 cm is set in the sand well, the lower end of the eluent pipe is positioned at the bottom of the sand well, and the upper end of the eluent pipe exposes the working cushion 5 cm, and is connected with the eluent pipe. The lotion input device is connected by a hose, and the length of the part of the rinse agent tube wrapped by the hose is 3cm;

[0059] Step 4, set the diameter of the vacuum filter tube on the vertical direction of the working cushion to be 7...

Embodiment 2

[0068] The heavy metal content of the sampled soil sample is Pb: 86mg / kg, Cd: 0.1mg / kg, Cr: 86mg / kg, Cu: 60mg / kg, Zn: 1600mg / kg

[0069] Step 1. On the planting land of 8m*8m*0.5m, drill bagged sand wells with a diameter of 10cm and a depth of 50cm. The spacing between the wells is 1.5m, and the arrangement of the sand wells is a square distribution, a total of 16;

[0070] Step 2, laying a deep silty clay working cushion on the surface, and the thickness of the working cushion is 7cm;

[0071] Step 3, setting a PVC eluent pipe in the sand well with a diameter of 9 cm, the lower end of the eluent pipe is located at the bottom of the sand well, and the upper end of the eluent pipe exposes the working cushion 5 cm, and is connected with the eluent pipe. The lotion input device is connected by a hose, and the length of the part of the rinse agent tube wrapped by the hose is 3cm;

[0072] Step 4, set the diameter of the vacuum filter tube on the vertical direction of the working ...

Embodiment 3

[0081] The heavy metal content of the sampled soil sample is Pb: 85mg / kg, Cd: 0.15mg / kg, Cr: 87mg / kg, Cu: 57mg / kg, Zn: 1588mg / kg

[0082] Step 1, on the planting land of 8m*8m*0.5m, drill bagged sand wells with a diameter of 10cm and a depth of 40cm, the well spacing is 1.5m, and the arrangement of the sand wells is a square distribution, a total of 16;

[0083] Step 2, laying a deep silty clay working cushion on the surface, and the thickness of the working cushion is 7cm;

[0084] Step 3, the diameter of the PVC eluent pipe is set in the sand well to be 8cm, the lower end of the eluent pipe is located at the bottom of the sand well, the upper end of the eluent pipe exposes the working cushion 5cm, and is connected with the eluent pipe. The lotion input device is connected by a hose, and the length of the part of the rinse agent tube wrapped by the hose is 5cm;

[0085] Step 4, set the diameter of the vacuum filter tube on the vertical direction of the working cushion to be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com