Nano-material modified silicone acrylic emulsion and application thereof

A technology of nano-materials and modified silicon, which is applied in the direction of adhesive types, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of insufficient overall strength, poor wettability and permeability, and poor mildew resistance, etc., to achieve Good reinforcement effect and improved wettability and permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

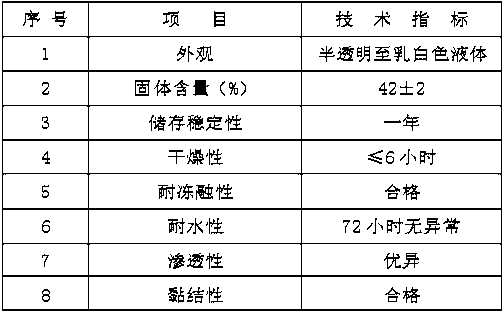

Image

Examples

Embodiment 1

[0019] Example 1 A nanomaterial-modified silicon-acrylic emulsion, which is made of the following raw materials in the weight ratio (g / g): 65% of silicone-modified acrylic emulsion, 1% of pH regulator, 30% of nanomaterials, Dry film antifungal agent 2%, hydrophobic agent 2%.

[0020] Wherein: nano material refers to nano silicon dioxide. The pH adjuster refers to ammonia water.

[0021] The preparation method of the nano-material modified silicon acrylic emulsion refers to: firstly weigh according to the proportion, then add the silicone modified acrylic emulsion into the reaction kettle to start stirring, add a pH regulator to adjust the pH value to 8~9; then add nano For materials, heat up to 84±2°C for 1 hour, cool down to below 40°C; finally add dry film antifungal agent, hydrophobic agent, and deionized water, stir for 20-30 minutes, filter and pack.

[0022] The application of this nano-material modified silicone acrylic emulsion comprises the following steps:

[0023...

Embodiment 2

[0027] Example 2 A nanomaterial-modified silicon-acrylic emulsion, which is made of the following raw materials in the weight ratio (g / g): 75% of silicone-modified acrylic emulsion, 2% of pH regulator, 10% of nanomaterials, Dry film antifungal agent 1.5%, hydrophobic agent 1.5%, deionized water 10%.

[0028] Wherein: nano material refers to nano titanium dioxide. The pH adjuster refers to an alkylamine.

[0029] The preparation method of the nano-material modified silicon-acrylic emulsion is the same as that in Example 1.

[0030] The application of this nano-material modified silicone acrylic emulsion comprises the following steps:

[0031] ⑴Diluent ratio: absolute ethanol and water are calculated and mixed according to the volume ratio of 4:1 (mL / mL), and the diluent is obtained;

[0032] (2) Calculate the total amount of diluent to be added according to the concentration of solid content of 1~10%;

[0033] (3) Calculate the required amount of water and ethanol respectiv...

Embodiment 3

[0035] Example 3 A nanomaterial-modified silicon-acrylic emulsion, which is made of the following raw materials in the weight ratio (g / g): 70% of silicone-modified acrylic emulsion, 3% of pH regulator, 18.6% of nanomaterials, Dry film antifungal agent 1.8%, hydrophobic agent 1.6%, deionized water 5%.

[0036] Wherein: nano material refers to nano silicon dioxide. The pH adjuster refers to ammonia water.

[0037] The preparation method of the nano-material modified silicon-acrylic emulsion is the same as that in Example 1.

[0038] The application of this nano-material modified silicone acrylic emulsion comprises the following steps:

[0039] ⑴Diluent ratio: absolute ethanol and water are calculated and mixed according to the volume ratio of 2.5:1 (mL / mL), and the diluent is obtained;

[0040] (2) Calculate the total amount of diluent to be added according to the concentration of solid content of 1~10%;

[0041] (3) Calculate the required amount of water and ethanol respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com