Preparation method of oil recovery sand-carrying fluid treatment agent

A treatment agent and sand-carrying liquid technology, applied in chemical instruments and methods, mining fluids, earthwork drilling, etc., can solve problems such as weak wetting and penetration ability, inability to maximize functions, and inability to achieve compatibility. To achieve the effect of improving wetting and penetrating ability, increasing sand-carrying function, and increasing clay stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0009] The preparation method of oil recovery sand-carrying fluid treatment agent is characterized in that it includes the following steps: (a) material selection: 50% dimethylamine-epichlorohydrin polycondensate, the dimethylamine-epoxychlorohydrin polycondensate Appearance: light yellow-yellow viscous liquid, solid content greater than or equal to 50%, less than 100%, pH value at 1% concentration: 6-9, viscosity (CPS): 500-6500. 20% propylene Amide-diethyldiallyl ammonium chloride copolymer, the appearance of the described acrylamide-diethyldiallyl ammonium chloride copolymer: pale yellow viscous liquid; solid content: 10% to 20% %; pH value at 1% concentration: 3-7, viscosity (cps): 500-12000cps. 25% diallylamine-acrylamide-dimethyl diallyl ammonium chloride copolymer, 5% potassium chloride; (b) mixing: put the raw materials into the reaction kettle, start stirring, and fully stir Uniform, used as oil recovery sand-carrying fluid treatment agent.

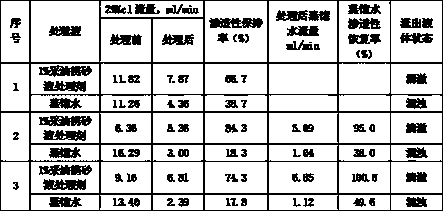

[0010] Experimental met...

Embodiment 2

[0030] In this embodiment, the technical scheme is basically the same as that in Embodiment 1, the only difference is that the polycondensate of dimethylamine-epichlorohydrin accounts for 48% of the total content, and the polycondensate of diallylamine-acrylamide-dimethyl diene Propyl ammonium chloride copolymer accounts for 25% of the total content, potassium chloride accounts for 7% of the total content, and acrylamide-diethyl diallyl ammonium chloride copolymer accounts for 20% of the total content.

Embodiment 3

[0032] In this embodiment, the technical scheme is basically the same as that in Embodiment 1, the only difference is that the polycondensate of dimethylamine-epichlorohydrin accounts for 52% of the total content, and the polycondensate of diallylamine-acrylamide-dimethyl diene Propyl ammonium chloride copolymer accounts for 25% of the total content, potassium chloride accounts for 3% of the total content, and acrylamide-diethyl diallyl ammonium chloride copolymer accounts for 20% of the total content.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com