Cast aluminum alloy of high-strength high-toughness thin-wall structural member and preparation method thereof

A technology for casting aluminum alloys and structural parts, applied in the field of aluminum alloy processing, can solve the problems of high strength and high toughness, easy fatigue cracking, and low toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

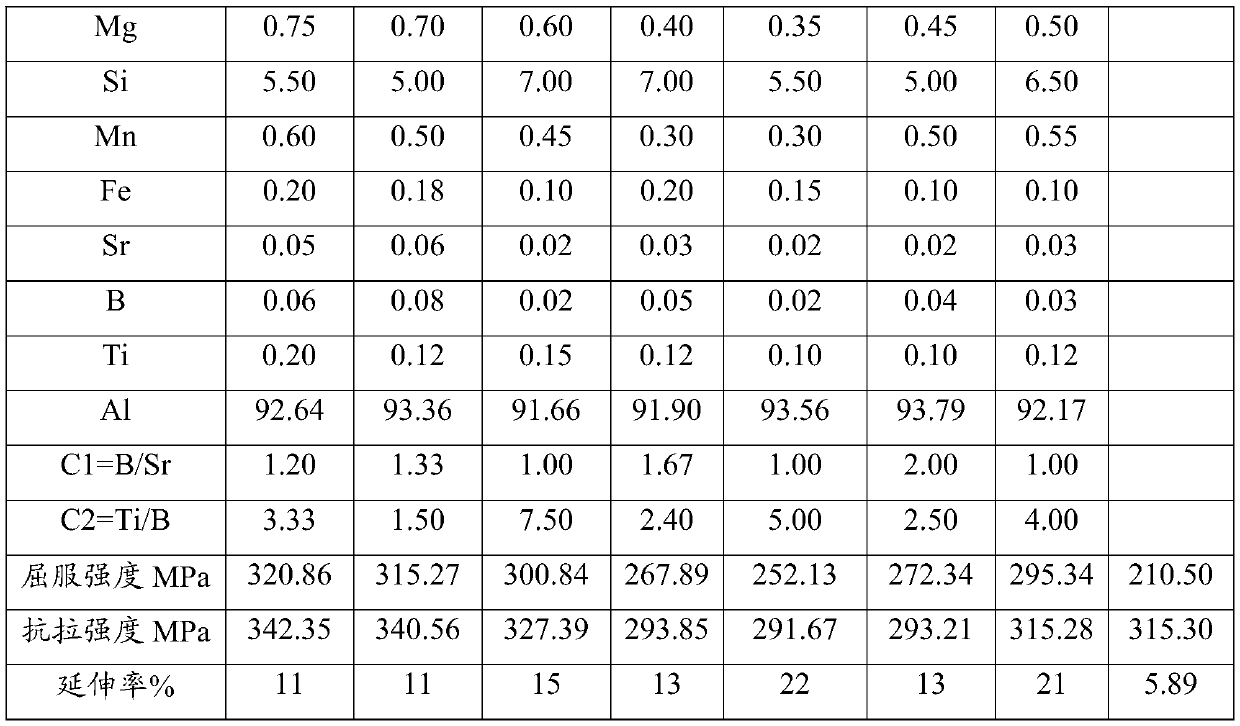

Examples

Embodiment 1

[0046] The content of each component of cast aluminum alloy for high-strength and tough thin-walled structural parts is expressed in weight percentage as follows: Al 96.73%, Si 3.00%, Mg 0.10%, Mn 0.10%, Sr 0.01%, B 0.01%, Ti 0.05%. The preparation method of the cast aluminum alloy of the high-strength and tough thin-walled structural part comprises the following steps:

[0047] 1S ingredients: Al-20Si alloy, 99.95% magnesium ingot, 99.8% aluminum ingot, Al-10Ti alloy, Al-40Mn alloy, Al-10Sr alloy, Al-5Ti-1B alloy, iron source are selected according to the above composition 99.95% iron powder or aluminum-iron master alloy;

[0048] 2S smelting and die-casting: Add the raw materials obtained in step 1S into the induction melting furnace, vacuumize, pass argon, and melt at a temperature of 730-760°C to obtain a melt solution; use mechanical stirring method, stir for 8-10min , cast into ingots;

[0049] 3S homogenization: the ingot obtained in step 2S is subjected to homogeniza...

Embodiment 2

[0053] The content of each component of cast aluminum alloy for high-strength and tough thin-walled structural parts is expressed in weight percentage as follows: Al86.98%, Si 10.00%, Mg 1.00%, Mn 1.00%, Sr 0.10%, B 0.12%, Ti 0.20%, Fe 0.60%. The preparation method of the cast aluminum alloy of the high-strength and tough thin-walled structural part comprises the following steps:

[0054] 1S ingredients: Al-20Si alloy, 99.95% magnesium ingot, 99.8% aluminum ingot, Al-10Ti alloy, Al-40Mn alloy, Al-10Sr alloy, Al-5Ti-1B alloy, iron source are selected according to the above composition 99.95% iron powder or aluminum-iron master alloy;

[0055] 2S smelting and die-casting: Add the raw materials obtained in step 1S into the induction melting furnace, vacuumize, flow argon, and melt at a temperature of 730-760°C to obtain a melt solution; use electromagnetic stirring method, stir for 8-10min , cast into ingots;

[0056] 3S homogenization: the ingot obtained in step 2S is subject...

Embodiment 3

[0060] The content of each component of cast aluminum alloy for high-strength and tough thin-walled structural parts is expressed in weight percentage as follows: Al 95.45%, Si 4.00%, Mg 0.25%, Mn 0.20%, Sr 0.01%, B 0.01%, Ti 0.08%. The preparation method of the cast aluminum alloy of the high-strength and tough thin-walled structural part comprises the following steps:

[0061] 1S ingredients: Al-20Si alloy, 99.95% magnesium ingot, 99.8% aluminum ingot, Al-10Ti alloy, Al-40Mn alloy, Al-10Sr alloy, Al-5Ti-1B alloy, iron source are selected according to the above composition 99.95% iron powder or aluminum-iron master alloy;

[0062] 2S smelting and die-casting: Add the raw materials obtained in step 1S into the induction melting furnace, vacuumize, flow argon, and melt at a temperature of 730-760°C to obtain a melt solution; use ultrasonic vibration method and stir for 8-10 minutes , cast into ingots;

[0063] 3S homogenization: the ingot obtained in step 2S is subjected to h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com