Preparation method of niobium-tungsten-molybdenum-zirconium alloy ingot

A zirconium alloy and niobium-tungsten technology is applied in the field of preparation of niobium-tungsten-molybdenum-zirconium alloy ingots, which can solve the problems affecting the consistency of material structure and performance, and achieve the effect of low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation method of the niobium-tungsten-molybdenum-zirconium alloy ingot of the present embodiment comprises the following steps:

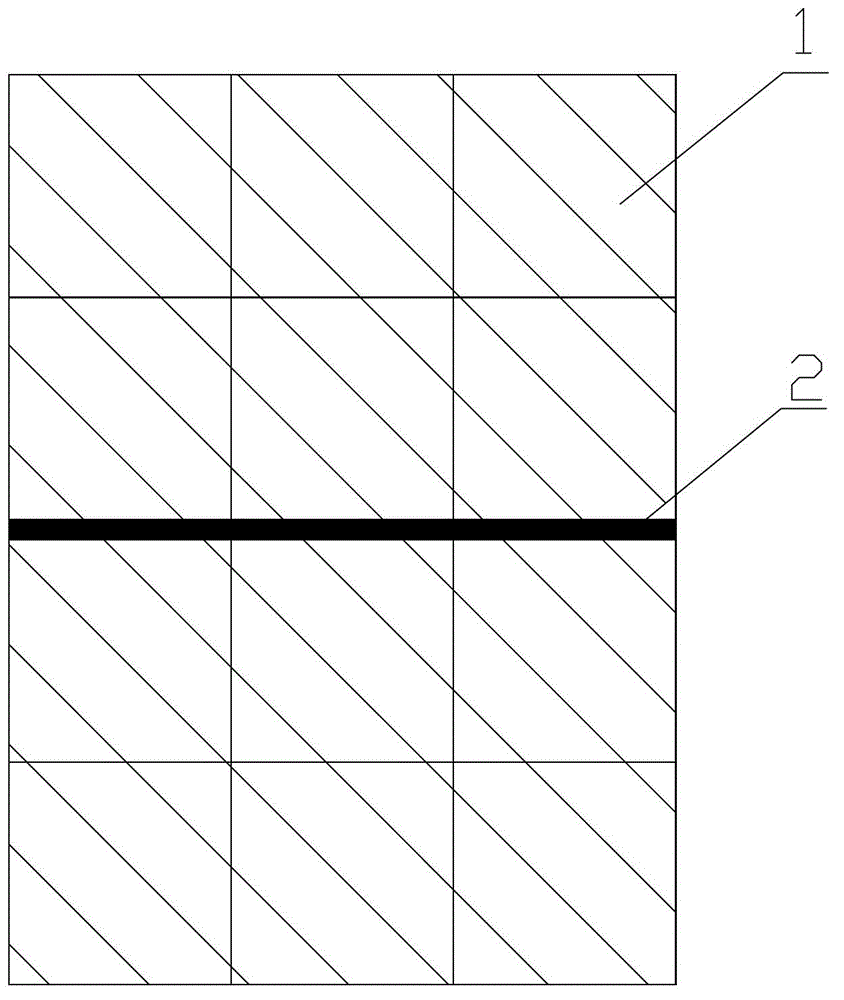

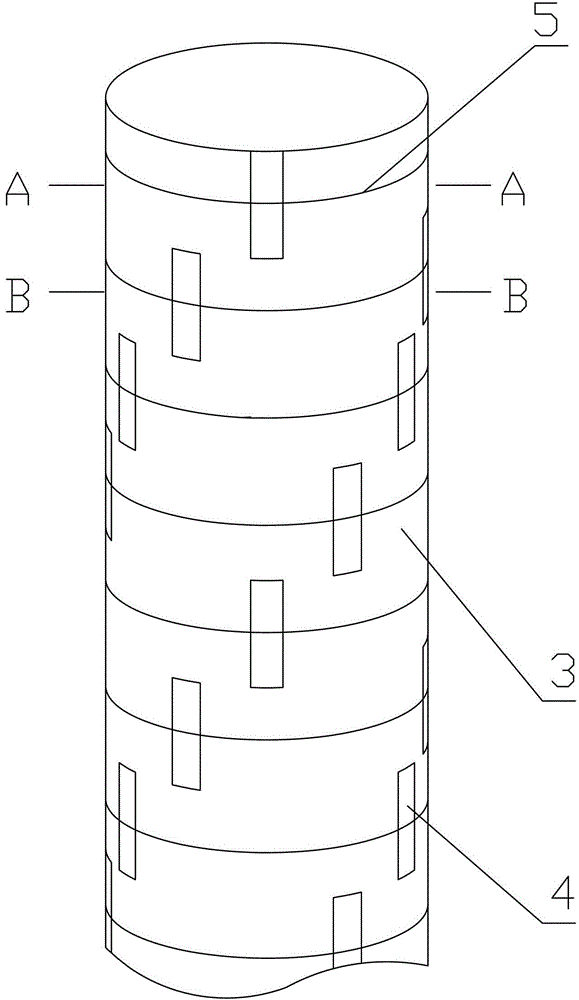

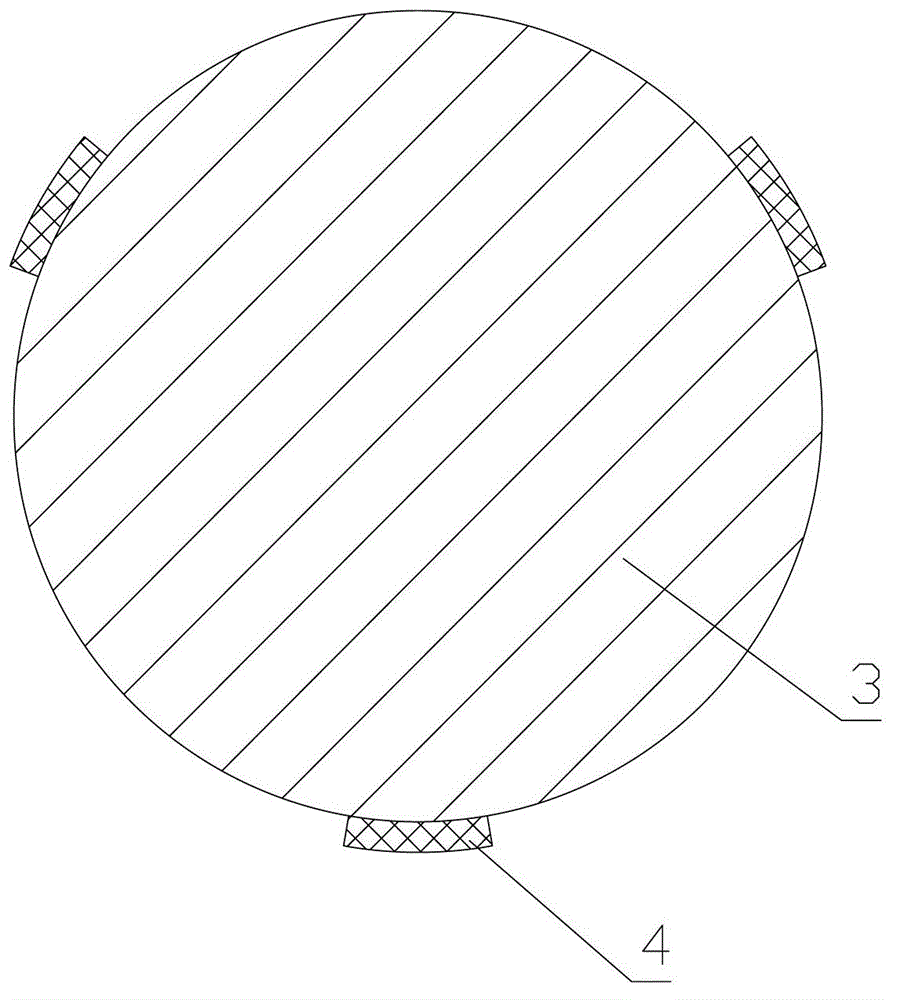

[0030] Step 1. Neatly stack 48 niobium-tungsten-molybdenum metal strips 1 with a width and thickness of 14mm and a length of 300mm, so that the length of the neatly stacked niobium-tungsten-molybdenum metal strips is 1200mm, the width is 42mm, and the thickness is 56mm , and lay the first pure zirconium plate 2 horizontally in the middle of the neatly stacked niobium-tungsten-molybdenum metal strips, then place the niobium-tungsten-molybdenum metal strips with the first pure zirconium plates 2 in the argon arc welding box, and place the first The pure zirconium plate 2 and the neatly stacked niobium-tungsten-molybdenum metal strips are argon-arc welded to obtain a smelting electrode with a weight of 22.6Kg; the length and width of the first pure zirconium plate 2 are the same as the neatly stacked niobium-tungsten Molybdenum metal st...

Embodiment 2

[0040] The preparation method of the niobium-tungsten-molybdenum-zirconium alloy ingot of the present embodiment comprises the following steps:

[0041] Step 1. Neatly stack 24 niobium-tungsten-molybdenum metal strips 1 with a width and thickness of 15mm and a length of 600mm, so that the length of the neatly stacked niobium-tungsten-molybdenum metal strips is 1200mm, the width is 45mm, and the thickness is 60mm , and lay the first pure zirconium plate 2 horizontally in the middle of the neatly stacked niobium-tungsten-molybdenum metal strips, then place the niobium-tungsten-molybdenum metal strips with the first pure zirconium plates 2 in the argon arc welding box, and place the first The pure zirconium plate 2 and the neatly stacked niobium-tungsten-molybdenum metal strips are argon-arc welded to obtain a smelting electrode with a weight of 27.2Kg; the length and width of the first pure zirconium plate 2 are the same as the neatly stacked niobium-tungsten Molybdenum metal st...

Embodiment 3

[0051] The preparation method of the niobium-tungsten-molybdenum-zirconium alloy ingot of the present embodiment comprises the following steps:

[0052] Step 1. Neatly stack 12 niobium-tungsten-molybdenum metal strips 1 with a width and thickness of 16mm and a length of 1200mm, so that the length of the neatly stacked niobium-tungsten-molybdenum metal strips is 1200mm, the width is 48mm, and the thickness is 64mm, and lay the first pure zirconium plate 2 horizontally in the middle of the neatly stacked niobium-tungsten-molybdenum metal strips, and then place the niobium-tungsten-molybdenum metal strips with the first pure zirconium plates 2 in the argon arc welding box. A pure zirconium plate 2 and neatly stacked niobium-tungsten-molybdenum metal strips are argon-arc welded to obtain a smelted electrode with a weight of 29.9Kg; the length and width of the first pure zirconium plate 2 are the same as the neatly stacked niobium The tungsten and molybdenum metal strips are the sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com