An automatic feeding device for rare earth electrolysis and its operating method

An automatic feeding, rare earth technology, applied in the direction of electrolysis components, electrolysis process, etc., can solve the problems of increasing production costs, flying materials, labor intensity of workers, etc., achieving the effect of reasonable design, reducing labor intensity, and improving the environment of the production workshop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

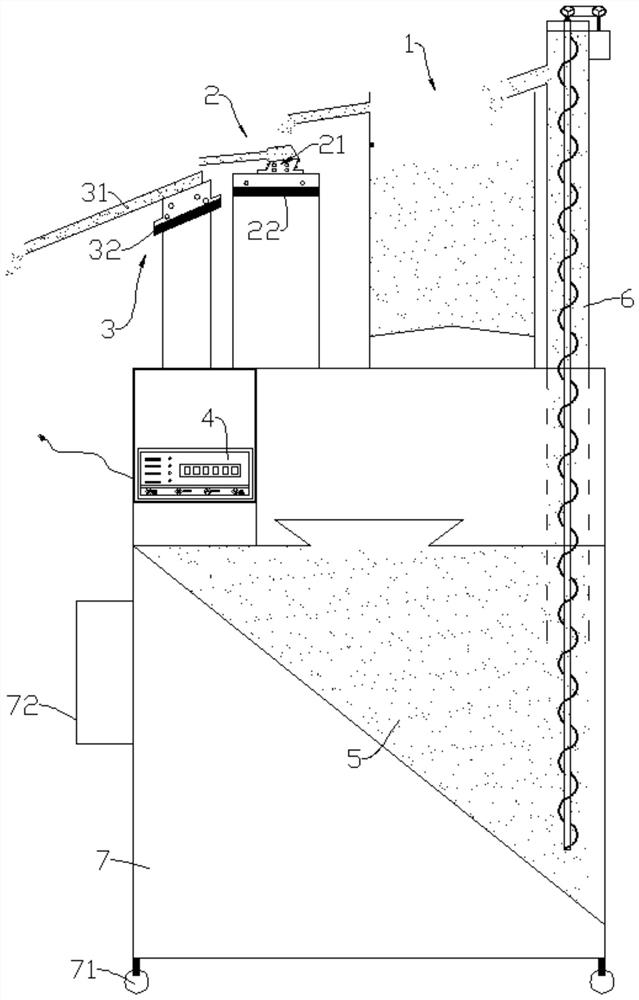

[0041] Such as figure 1 As shown, this embodiment provides an automatic feeding device for rare earth electrolysis, including a material temporary storage device 1 for controlling the total amount of feeding, a quantitative device 2 for controlling the single feeding amount of materials, and a device for evenly feeding materials. The feeding device 3; the material temporary storage device 1, the quantitative device 2 and the feeding device 3 are sequentially connected through the material channel to allow the materials to flow in sequence, and the outlet of the feeding device 3 extends above the rare earth electrolytic cell for feeding materials to the rare earth electrolytic cell ;

[0042] The material temporary storage device 1 can be any device or combination of devices that has the function of storing materials and transporting materials to other devices, such as a combination of a barrel and a material conveyor, and a preferred implementation mode adopted in this embodimen...

Embodiment 2

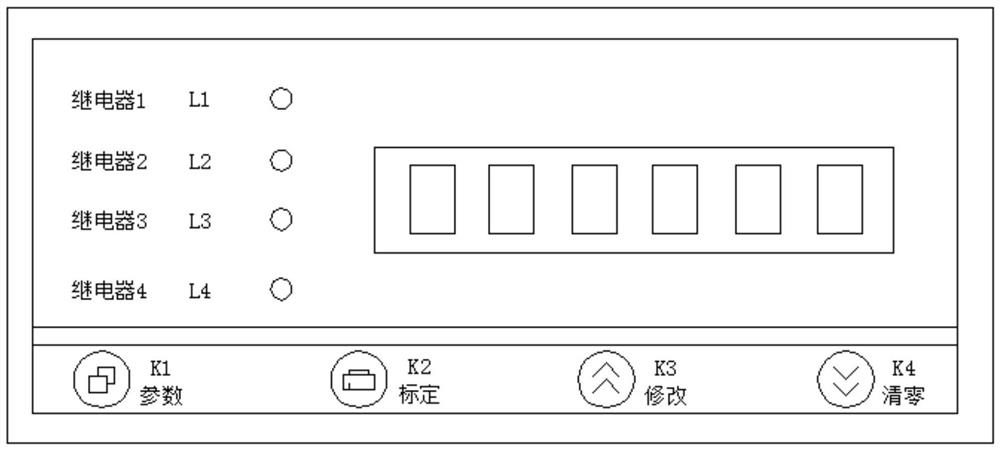

[0070] The controller used in this embodiment is as image 3As shown, the device can only be set for a single feeding amount under the user interface, and the button setting on the controller ensures that the equipment is easy to operate and prevents workers from causing system disturbance due to misoperation. From left to right on the control panel are k1, k2, k3, k4, the specific method of setting a single feeding amount: long press k1 in standby mode, it will display 000000, press k4 to move the cursor, press k3, it will display 000000, press k1, it will display Ed-001, press k4 to move the cursor, press k3 to modify it to 000x00, x is the set single feeding amount (unit: gram, if x is 3, it is 300g), press k1 to confirm the value, press k2 to return to control interface.

[0071] Under the administrator interface, the equipment can set the feeding times, feeding time interval, system delay time and electronic metering system correction and other functions. According to t...

experiment example

[0073] The automatic feeding equipment can realize regular, quantitative and uniform feeding in multiple feeding cycles, and the specific effects are shown in Table 1 (in the simulation test, an electronic scale is used to measure the actual feeding amount).

[0074] Table 1

[0075]

[0076] During the operation of the automatic feeding equipment, materials were randomly picked five times and compared with a balance with an accuracy of 1 mg. The comparison results are shown in Table 2 (the single feeding amount of the feeding equipment is 100 g).

[0077] Table 2

[0078]

[0079] The automatic feeding equipment feeds evenly in multiple feeding cycles, so that the rare earth oxides in the electrolyte are fully electrolyzed, and the electrolysis efficiency and product quality are improved. The specific effects are shown in Table 3 (each cycle is 2h, and the material ratio is expressed in PN 2 o 3 material as an example).

[0080] table 3

[0081]

[0082] Regular,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com