A method for increasing carbon and desulfurizing phosphorus pig iron

A technology of phosphorus pig iron and raw materials, which is applied in the field of aluminum electrolysis production, can solve the problems of high processing cost, less than calcined coke carburization effect, and complicated raw materials, so as to reduce material flying loss, good carburization and desulfurization effect, and simple preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The embodiment of the present invention also provides a preparation method of an environment-friendly phosphorus pig iron additive, which mainly includes the following steps:

[0036] S1. Crushing: crush the solid carbon blocks obtained by vacuum metallurgical treatment of waste cathode carbon blocks, and pass through a 5mm screen to obtain solid carbon as a carbon material, that is, a carburizing and desulfurizing agent. The purpose of crushing is to obtain solid particles with uniform particles carbon.

[0037] Among them, the solid carbon is prepared according to the following method: put the waste cathode carbon block in a vacuum metallurgical furnace, vacuumize and heat distillation, the vacuum degree is 10-50Pa, the heating distillation temperature is 850-1200°C, and the heating distillation time is 1-50Pa. 3h, after the distillation is completed, solid charcoal is collected in the furnace body of the vacuum metallurgy furnace.

[0038] S2. Ingredients: Prepare t...

Embodiment 1

[0065] Embodiment 1 provides an environmentally friendly phosphorus pig iron additive, which is obtained by the following preparation steps:

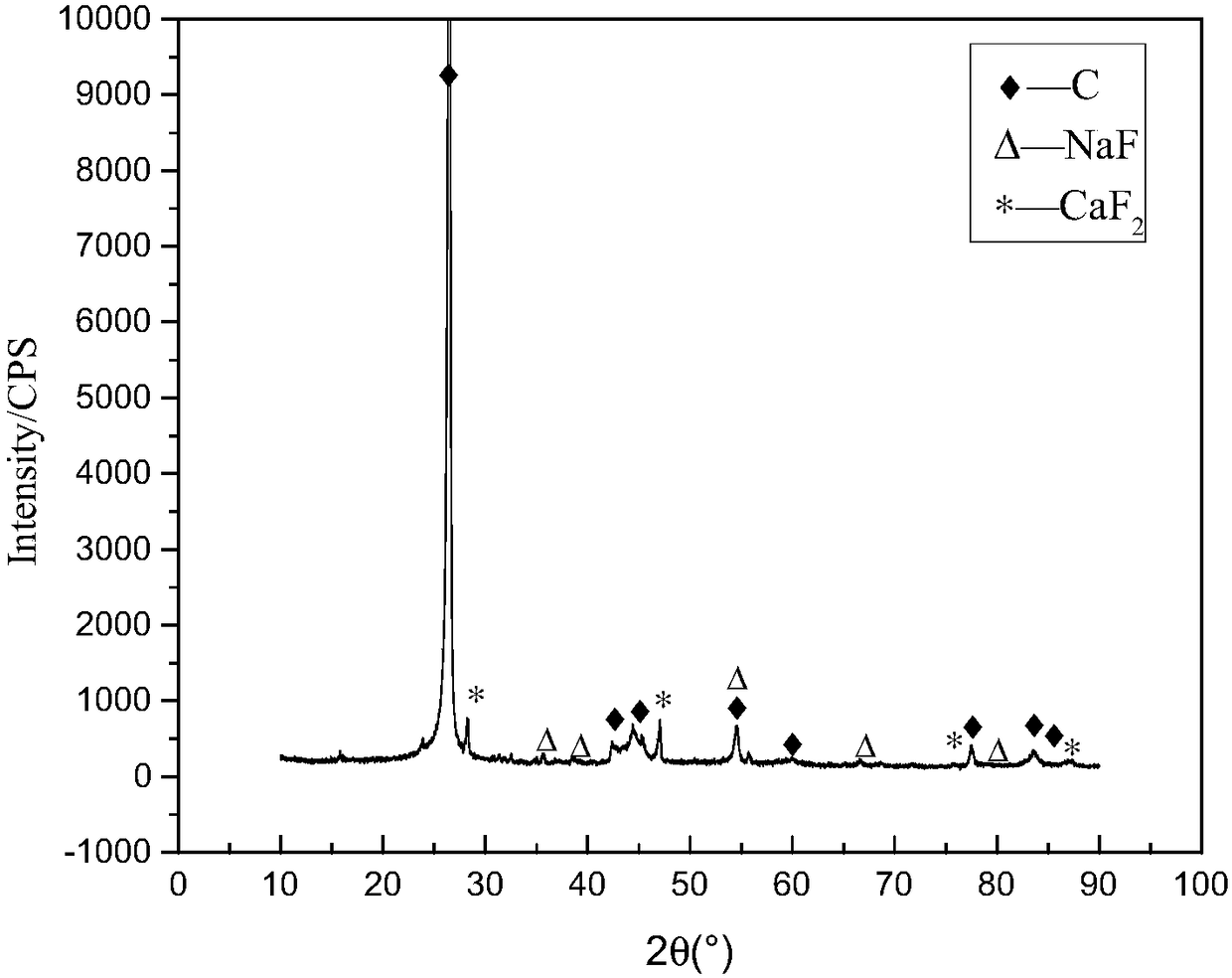

[0066] Preparation of solid carbon: Vacuum metallurgical treatment of the waste cathode carbon block, the particle size of the waste cathode carbon block is 25mm, the vacuum metallurgical conditions are: vacuum degree of 10Pa, metallurgical temperature of 1100°C, and metallurgical time of 2.5h to obtain solid carbon, in which The carbon C content is 98.9%. The phase analysis diagram of the solid carbon is shown in figure 1 shown by figure 1 It can be seen that the solid carbon is mainly composed of C, CaF 2 , NaF composition.

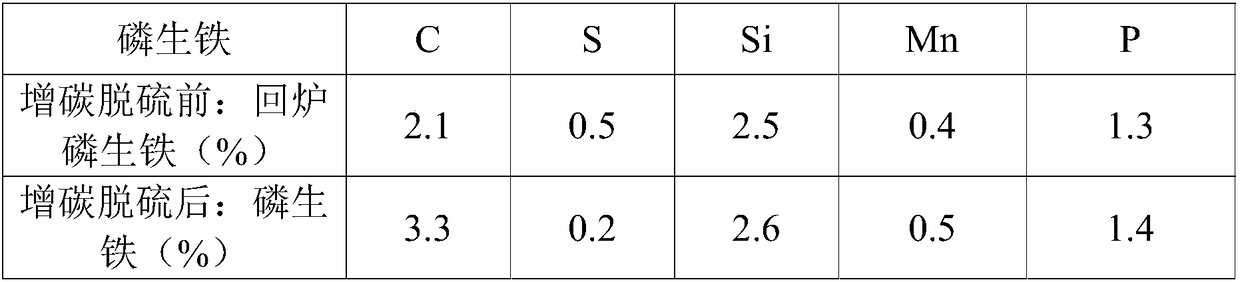

[0067] Prepare raw materials: 9.65kg carbon material (select solid carbon with a particle size below 5mm, which is obtained by screening the solid carbon obtained through vacuum metallurgical treatment and passing through a 5mm screen), 0.3kg binder, the The binder is configured according to the ratio of sodi...

Embodiment 2

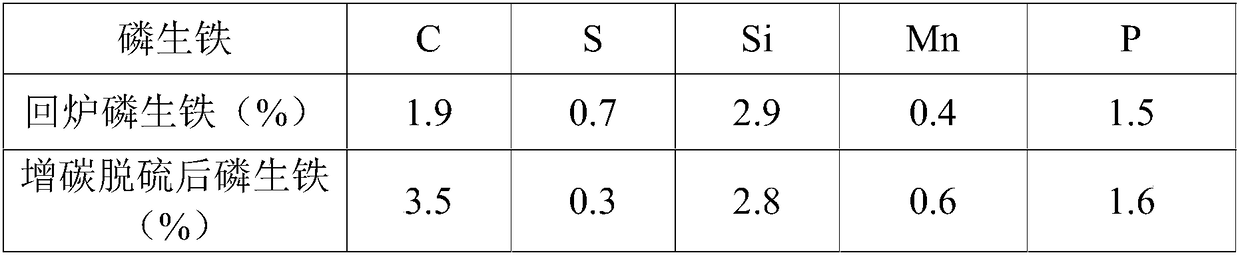

[0078] Embodiment 2 provides an environmentally friendly phosphorus pig iron additive, which is obtained by the following preparation steps:

[0079] Preparation of solid carbon: Vacuum metallurgical treatment of the waste cathode carbon block, the particle size of the waste cathode carbon block is 20mm, the vacuum metallurgical conditions are: vacuum degree of 20Pa, metallurgical temperature of 1000°C, and metallurgical time of 2h to obtain solid carbon, in which the fixed carbon The C content is 98.1%.

[0080] Prepare raw materials: 9.8kg carbon material (select solid carbon with a particle size below 5mm, which is obtained by screening the solid carbon obtained through vacuum metallurgical treatment and passing through a 5mm screen), 0.15kg binder, the The binder is configured according to the ratio of sodium fluorosilicate: (starch + polyvinyl alcohol) = 1:2, and 0.05kg of melting agent (sodium carbonate is selected).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com