Indoor composite floor based on phosphorous magnesium materials and self-leveling gypsum, and construction method of indoor composite floor

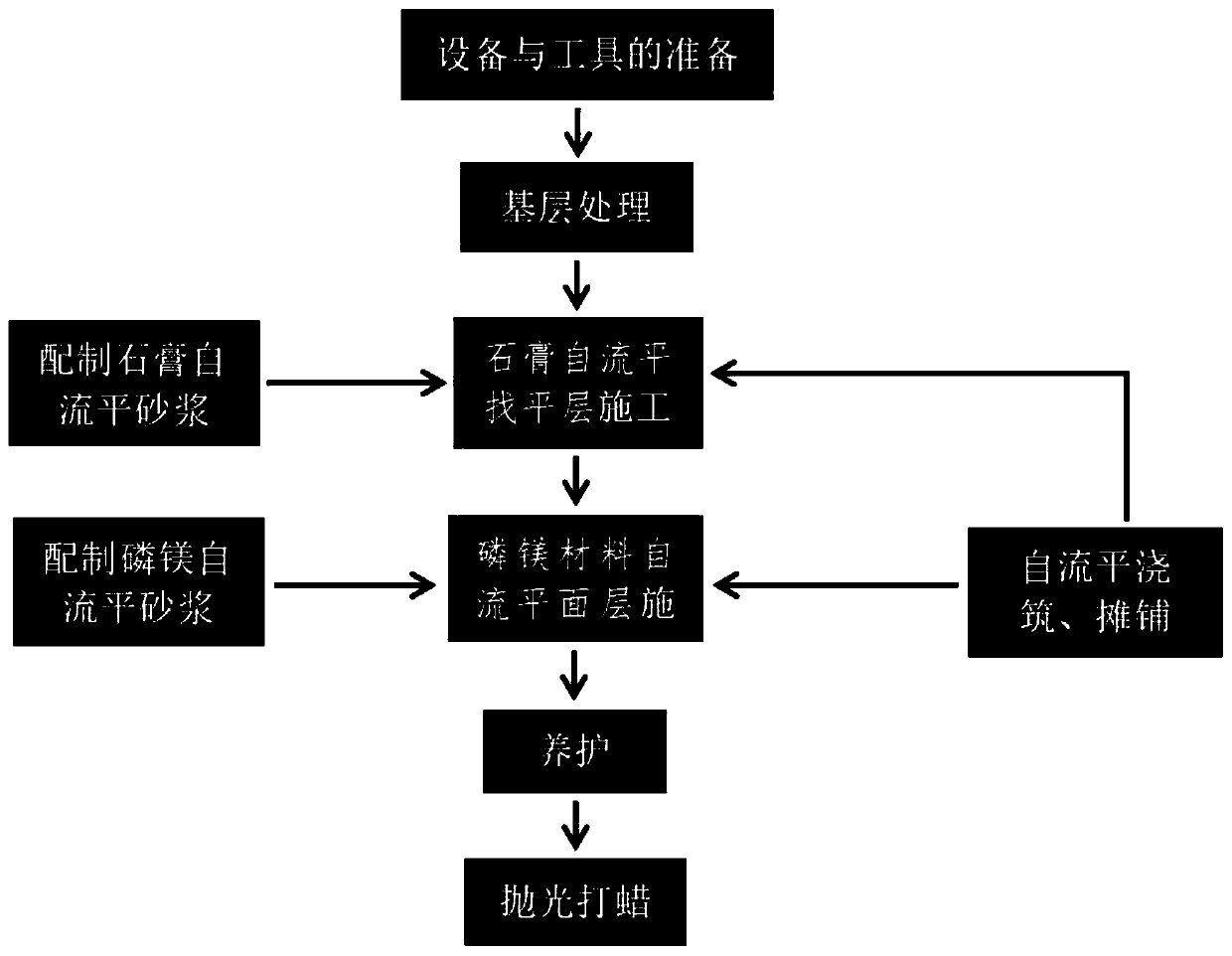

A self-leveling and internal compounding technology, applied to floors, buildings, building structures, etc., can solve problems such as long construction period, long initial setting time, and complicated construction procedures, so as to improve construction efficiency, save construction period, and simplify construction. The effect of construction procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

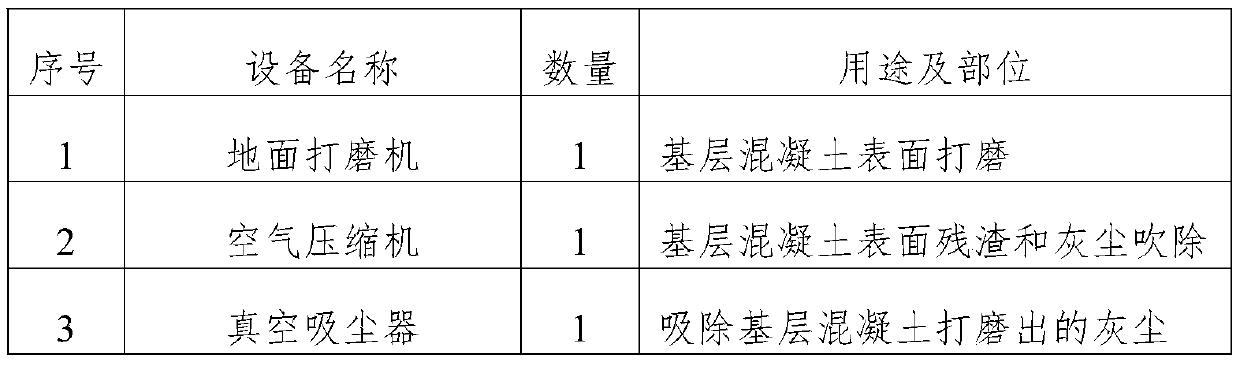

Method used

Image

Examples

Embodiment 1

[0042] Such as figure 2 As shown, an indoor composite floor based on phosphorus magnesium material and self-leveling gypsum, the indoor composite floor based on phosphorus magnesium material and gypsum self-leveling includes a concrete base 1, followed by concrete base 1, gypsum self-leveling from bottom to top A leveling layer 2 and a self-leveling layer 3 of phosphorus and magnesium materials, the gypsum self-leveling layer 2 is located between the concrete base 1 and the self-leveling layer 3 of phosphorus and magnesium materials; the gypsum self-leveling layer 2 is a gypsum self-leveling mortar layer, The gypsum self-leveling mortar penetrates into the concrete base layer 1 and combines with it during pouring; the self-leveling layer 3 of the phosphorus-magnesium material is a phosphorus-magnesium self-leveling mortar layer, and the phosphorus-magnesium self-leveling mortar penetrates into the gypsum self-leveling layer 2 during pouring Combined with it; the thicknesses o...

Embodiment 2

[0085] Such as figure 2 As shown, an indoor composite floor based on phosphorus magnesium material and self-leveling gypsum, the indoor composite floor based on phosphorus magnesium material and gypsum self-leveling includes a concrete base 1, followed by concrete base 1, gypsum self-leveling from bottom to top A leveling layer 2 and a self-leveling layer 3 of phosphorus and magnesium materials, the gypsum self-leveling layer 2 is located between the concrete base 1 and the self-leveling layer 3 of phosphorus and magnesium materials; the gypsum self-leveling layer 2 is a gypsum self-leveling mortar layer, The gypsum self-leveling mortar penetrates into the concrete base layer 1 and combines with it during pouring; the self-leveling layer 3 of the phosphorus-magnesium material is a phosphorus-magnesium self-leveling mortar layer, and the phosphorus-magnesium self-leveling mortar penetrates into the gypsum self-leveling layer 2 during pouring It is integrated with it; the thick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com