Preparation method of nano silver/micropore polymer composite liquid bactericide

A technology of microporous polymer and nano-silver, which is applied in the field of nanotechnology and fine chemical industry, can solve the problems of larger particle size, poor antibacterial effect, and less reaction interface, and achieve simple operation, long-lasting bactericidal effect, and monodispersity Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of nano-silver / microporous polymer composite bactericidal liquid, with 500 milliliters of this nano-silver / microporous polymer composite bactericidal liquid, the size of nano-silver particles in the nano-silver / microporous polymer composite bactericidal liquid is between 1 ~ 5nm Between, prepare according to the following preparation steps:

[0033] See the table below for raw materials and proportions:

[0034]

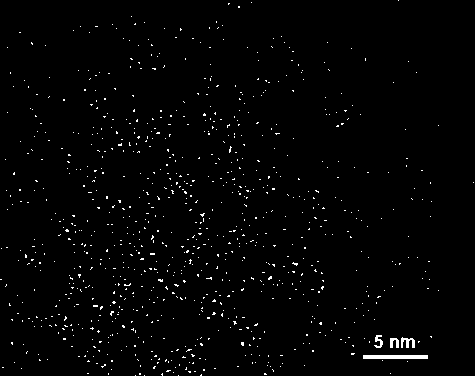

[0035] Preparation method: Add 2.0nl of mannitol and 0.5g of fine powder of triynylphenyl conjugated microporous polymer after grinding into 300ml of purified water, stir and dissolve, add 0.5g of silver nitrate (calculated as silver), and add purified water to 400 ml; raise the temperature, and leave to react in a sealed container at 50°C for 5 hours; after the completion of the reaction, stir slowly and add purified water to 500 ml to obtain the target nano-silver / microporous polymer composite sterilizing solution. figure 1 It is a high-resolution...

Embodiment 2

[0039] Based on 500 milliliters of this nano-silver / microporous polymer composite sterilizing solution, the raw materials and proportioning ratio are shown in the following table:

[0040]

[0041]Preparation method: add 3.0 ml of glucitol and 0.8 g of finely ground diacetylenylphenyl conjugated microporous polymer powder into 300 ml of purified water, stir to dissolve, add 0.5 g of silver acetate (calculated as silver), and add purified water to 400 ml; raise the temperature, and leave to react at 60°C for 6 hours; after the reaction is completed, stir slowly and add purified water to 500 ml to obtain the target nano-silver / microporous polymer composite sterilizing solution.

[0042] Bactericidal performance test: According to the 2002 edition of "Disinfection Technical Specifications", the bactericidal performance test is carried out. The test results show that the killing rate of the above-mentioned nano-silver / peroxide composite sterilizing solution on Escherichia coli ...

Embodiment 3

[0044] Based on 500 milliliters of this nano-silver / microporous polymer composite sterilizing solution, the raw materials and proportioning ratio are shown in the following table:

[0045]

[0046] Preparation method: Add 2.0ml of glucitol and 0.6g of finely ground diacetylenylphenyl conjugated microporous polymer powder into 300ml of purified water, stir to dissolve, add 0.4g of silver acetate (calculated as silver), and add purified Water to 400 ml; raise the temperature, and keep it closed for 5 hours at 60°C; after the reaction is completed, stir slowly and add purified water to 500 ml to obtain the target nano-silver / microporous polymer composite sterilizing solution.

[0047] Bactericidal performance test: According to the 2002 edition of "Disinfection Technical Specifications", the bactericidal performance test is carried out. The test results show that the killing rate of the above-mentioned nano-silver / peroxide composite sterilizing solution on Escherichia coli (ty...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com