Rolling method and rolling system of closed type profile steel

A closed, section steel technology, applied in metal rolling, metal rolling, rolls, etc., can solve the problems of difficult process design and on-site production, large loss of roll equipment, and difficult process design, etc., to shorten the development cycle, improve The effect of improving the yield of finished products and improving the utilization rate of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

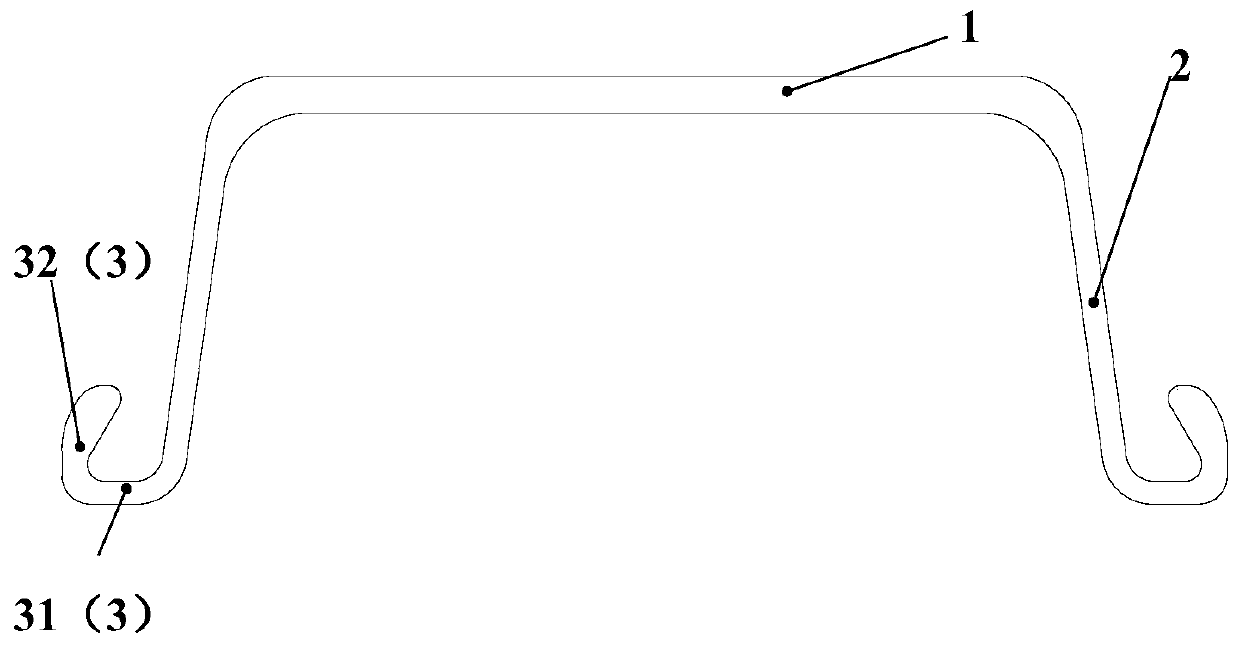

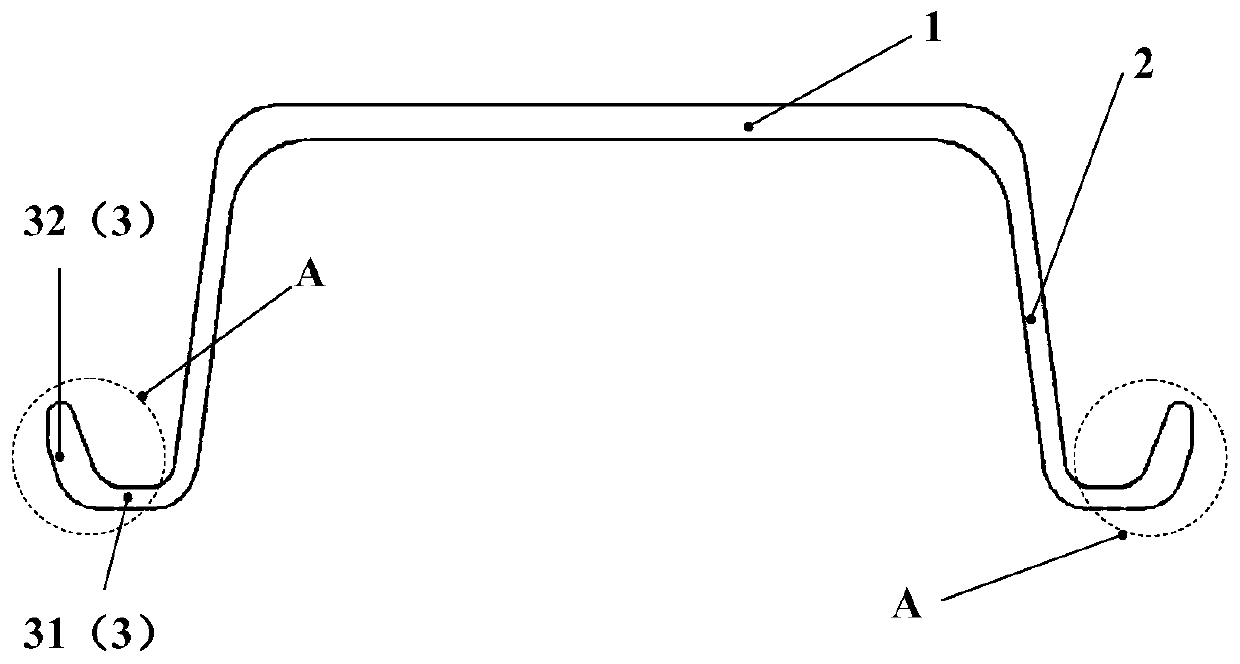

[0063] The finished steel sheet pile of a certain specification is as figure 1 , the steel sheet pile is composed of a bottom plate 1, a flange 2 and a locking opening 3, the locking opening 3 includes a bottom edge 31 and a side edge 32, one end of the bottom edge 31 is connected to the flange 2, and the other end of the bottom edge 31 extends outward and connects with the One end of the side 32 is connected, the other end of the side 32 is inclined to the side of the flange 2, the bottom 31 and the side 32 are connected to form a semi-closed lock 3, and the angle between the side 32 and the bottom 31 is an acute angle.

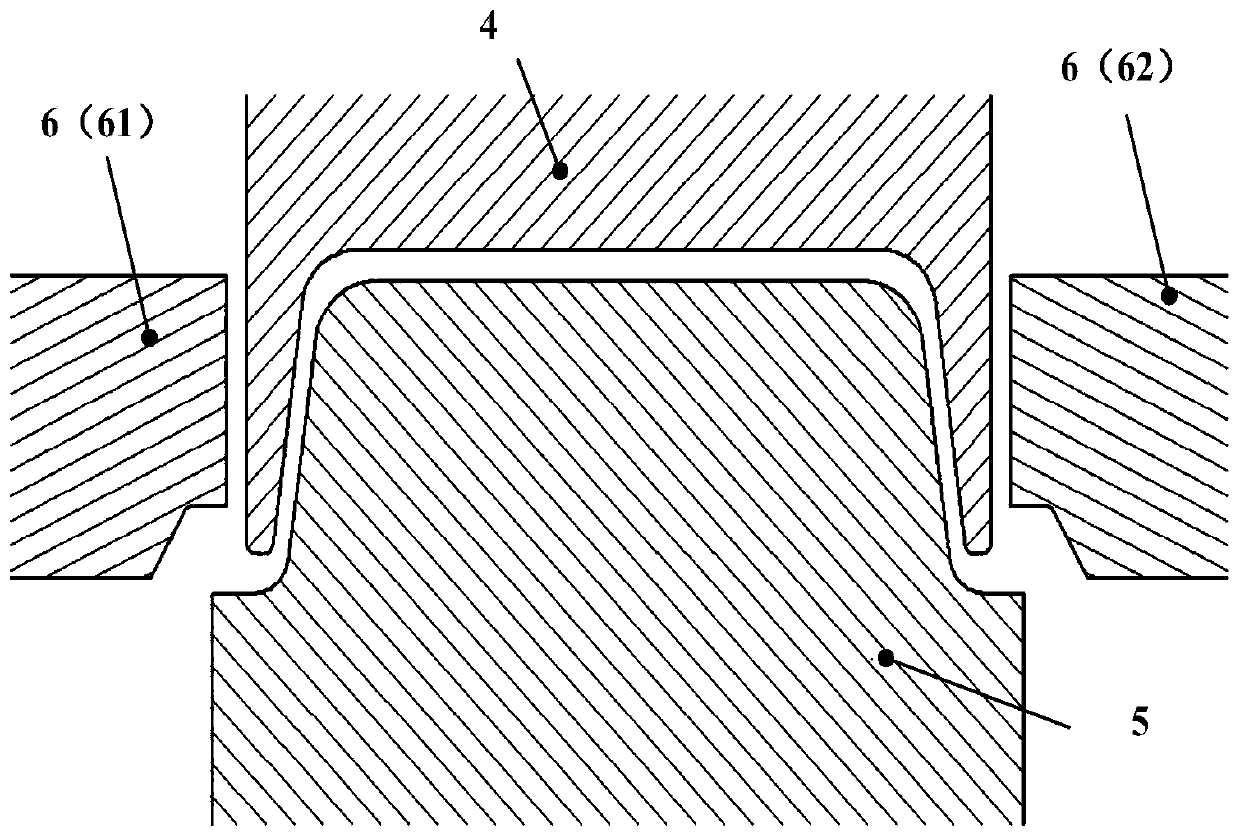

[0064] According to the steel sheet pile finished product, billet size and forming requirements, the inner bending part is designed as an open structure as a hot-rolled product, that is, the angle between the side 32 and the bottom 31 is an obtuse angle, and the angle of the obtuse angle can be It is 95°-110° to facilitate the rolling in the hot rolling step...

Embodiment 2

[0070] The finished product of a Hafen tank of a certain specification is as follows: Figure 5 As shown, the Hafen trough is composed of a horizontal plate 7, two vertical plates 8 and two folded plates 9, both ends of the horizontal plate 7 are connected to one end of a vertical plate 8, and the two vertical plates 8 are located at the same side, the other ends of the two vertical plates 8 are connected to one end of a folded plate 9, and the other ends of the two folded plates 9 are bent toward the middle of the Hafen groove, and the angle between the folded plate 9 and the vertical plate 8 is At right angles or acute angles, there is a gap between the other ends of the two folded plates 9 , and the two folded plates 9 and the gap between them form a notch 10 .

[0071] Design the pass type, according to the finished product of the Hafen slot, the size of the billet and the needs of forming, design the notch 10 as an open structure as a hot-rolled product, and the angle bet...

Embodiment 3

[0076] The finished hollow elevator guide rail of a certain specification is as follows: Figure 7 As shown, the hollow elevator guide rail is composed of a guide edge 13, two guide rail edges 12 and two installation edges 14. Both ends of the guide edge 13 are connected to one end of a guide rail edge 12, and the two guide rail edges 12 are located on the same side of the guide edge 13. side, the other ends of the two guide rail sides 12 are connected to one end of one installation side 14, and the other ends of the two installation sides 14 all extend to the outside of the hollow elevator guide rail, and the included angle between the guide side 13 and the guide rail side 12 is 90° °, the angle between the mounting edge 14 and the guide rail edge 12 is 90°, and the guide edge 13 and the two guide rail edges 12 jointly form a U-shaped mouth 11.

[0077] Design the pass type, according to the hollow elevator guide rail finished product, blank size and forming requirements, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com