Hydrogel adhesive capable of being repeatedly used and not damaging surface of substrate, and preparation method and application of hydrogel adhesive

A technology of hydrogel glue and substrate surface, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve problems such as weak adhesive force, difficult to remove, and damage substrates, and achieve The effect of increasing durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

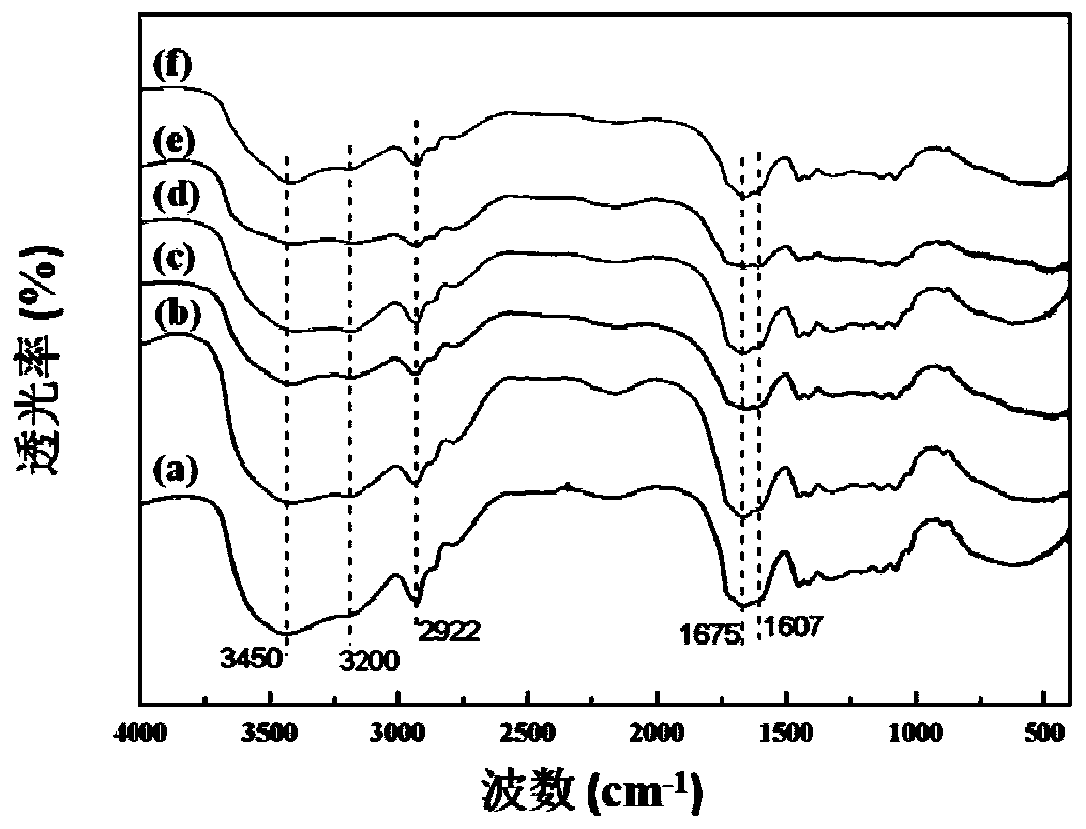

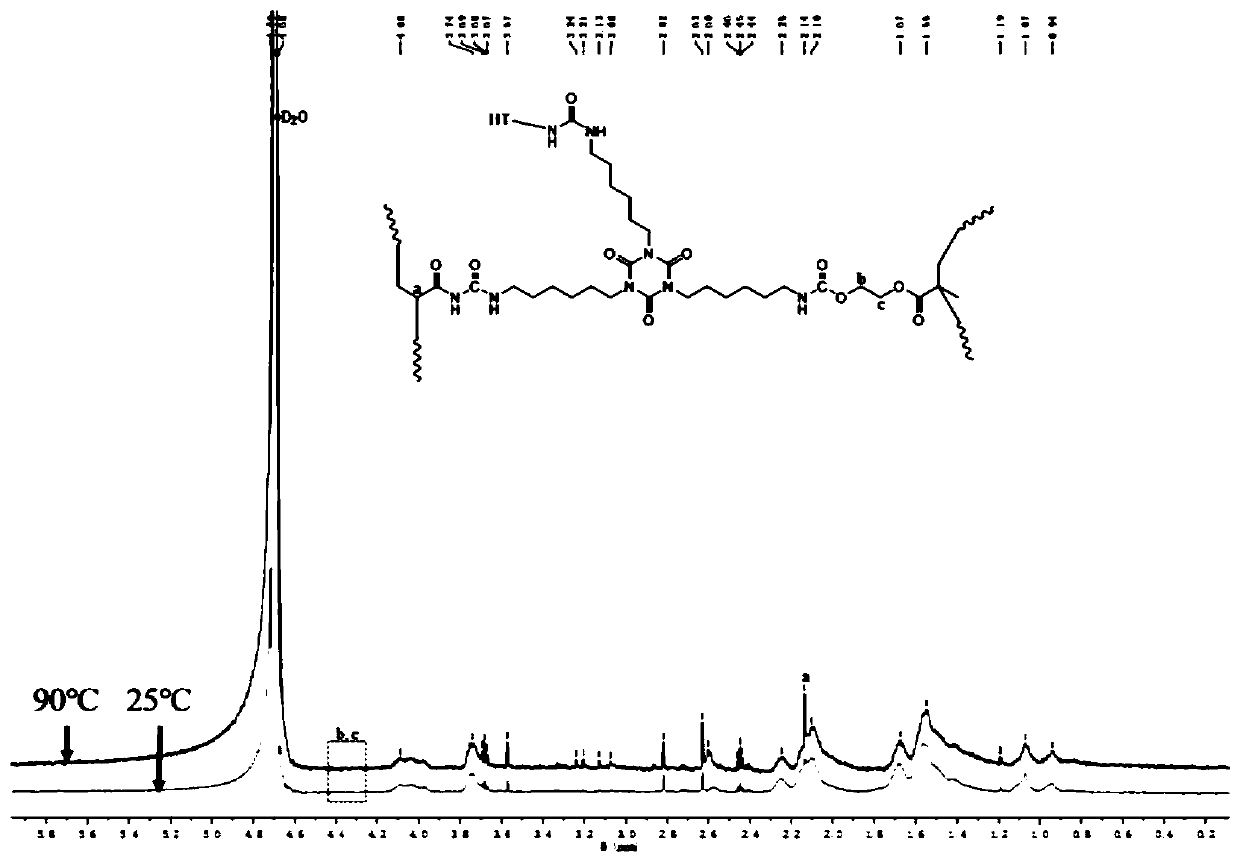

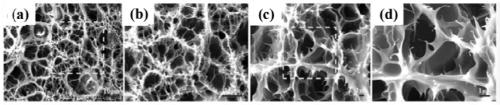

[0038] Embodiment 1: the synthesis of hydrogel adhesive

[0039] Mix 10 g of acrylamide, 4 g of hydroxyethyl methacrylate, 30 g of water, 0 μL of HT acetone solution (0.04 g / mL acetone solution), 0.1 g of ammonium persulfate, and 5 μL of tetramethylethylenediamine (TEMED) to obtain a hydrogel Glue the solution of the adhesive, and then pour it into the mold to undergo free radical polymerization to form a hydrogel. The free radical polymerization conditions are: 90 ° C for 3 minutes, followed by sufficient polymerization at room temperature for 2 hours. The water content of the obtained hydrogel adhesive was 68.2%.

Embodiment 2

[0041] Mix 10 g of acrylamide, 4 g of hydroxyethyl methacrylate, 30 g of water, 20 μL of HT acetone solution (0.04 g / mL acetone solution), 0.1 g of ammonium persulfate, and 5 μL of tetramethylethylenediamine (TEMED) to obtain a hydrogel Glue the solution of the adhesive, and then pour it into the mold to undergo free radical polymerization to form a hydrogel. The free radical polymerization conditions are: 90 ° C for 3 minutes, followed by sufficient polymerization at room temperature for 2 hours. The water content of the obtained hydrogel adhesive was 68.2%.

Embodiment 3

[0043] Mix 10 g of acrylamide, 4 g of hydroxyethyl methacrylate, 30 g of water, 40 μL of HT acetone solution (0.04 g / mL acetone solution), 0.1 g of ammonium persulfate, and 5 μL of tetramethylethylenediamine (TEMED) to obtain a hydrogel Glue the solution of the adhesive, and then pour it into the mold to undergo free radical polymerization to form a hydrogel. The free radical polymerization conditions are: 90 ° C for 3 minutes, followed by sufficient polymerization at room temperature for 2 hours. The water content of the obtained hydrogel adhesive was 68.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com