Two-stage hydrogen fuel cell stack gas supply device driven by motor

A technology of fuel cell stack and gas supply device, which is applied to fuel cells, fuel cell additives, electrical components, etc., can solve the problems of poor cooling effect and high cooling energy consumption, and achieves increased stability, increased reaction rate, and improved negative The effect of pressure capacity and use time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

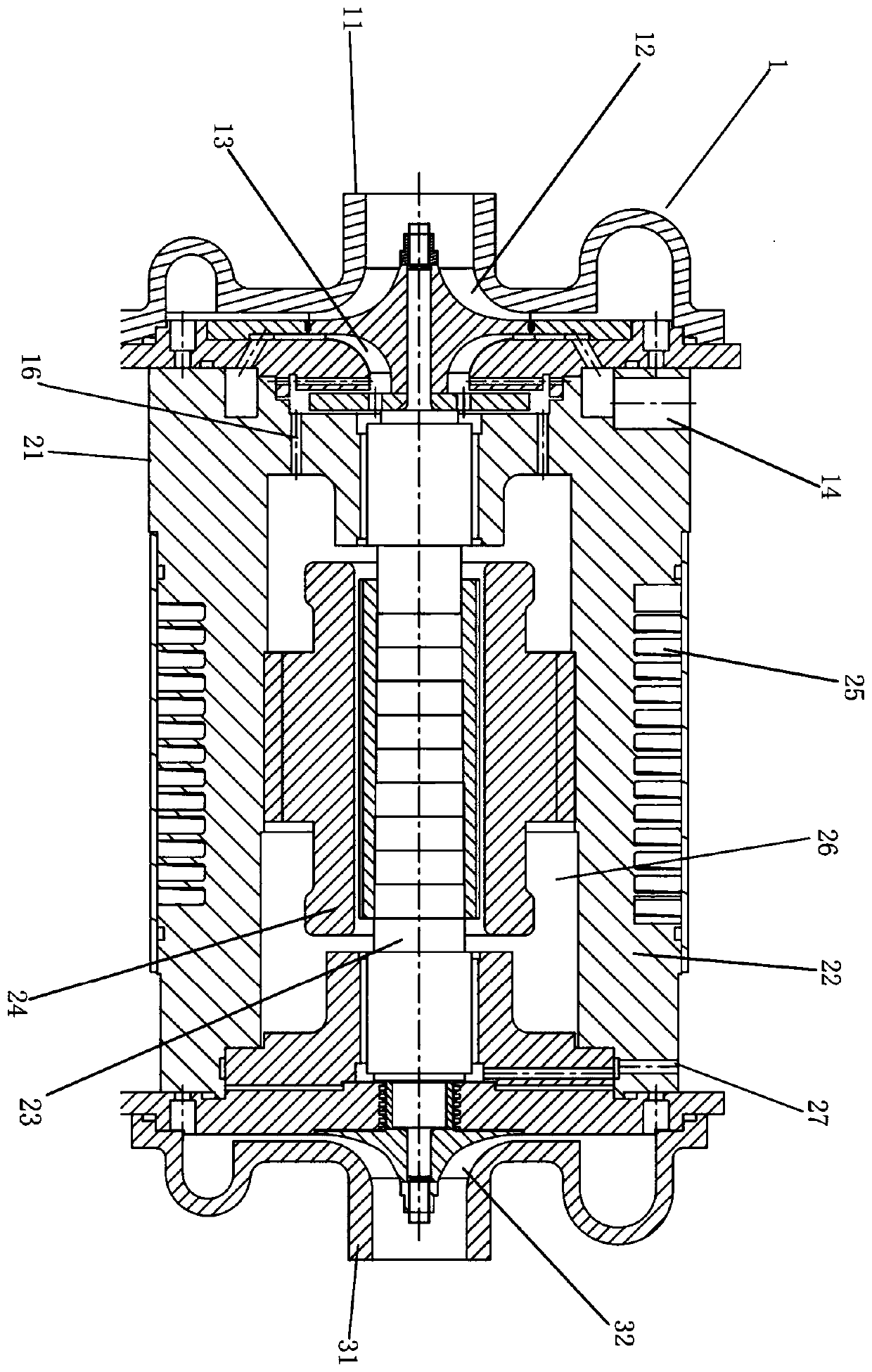

[0025] Such as figure 1 , image 3 as shown in

[0026] A two-stage hydrogen fuel cell stack gas supply device driven by an electric motor, comprising

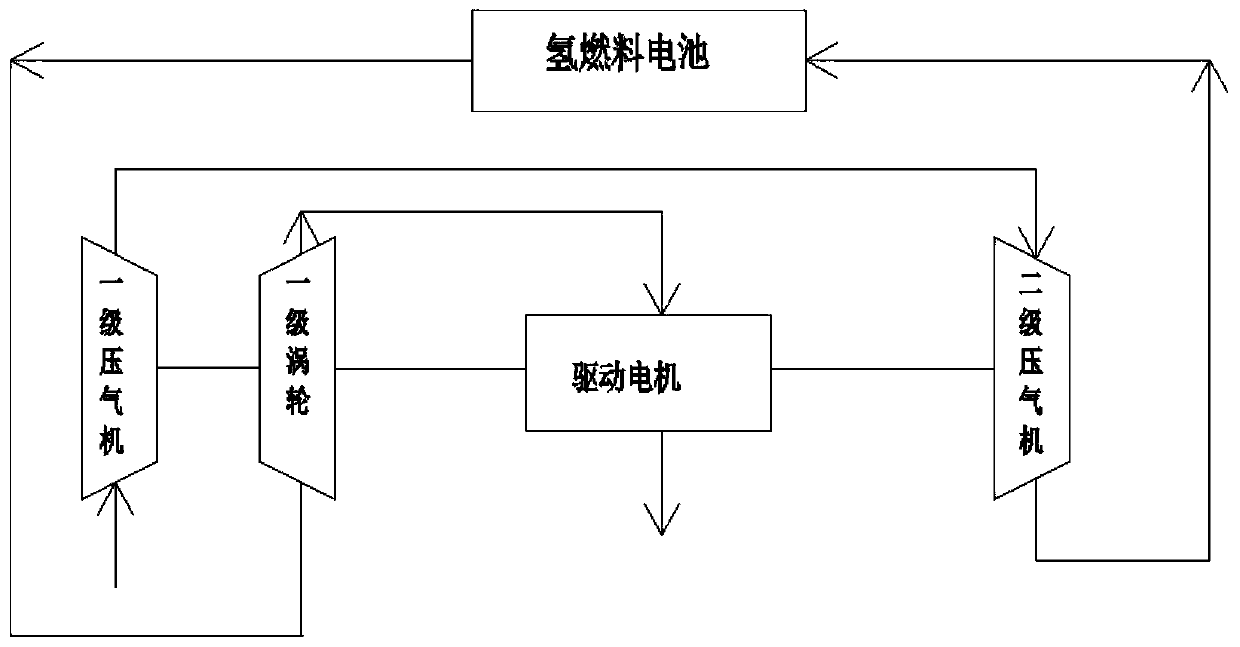

[0027] Drive motor 2, primary compressor 1, secondary compressor 3 and inter-stage communication pipeline, the drive motor 2 includes a motor housing 21, a motor stator 22, a motor main shaft 23 and a high-speed motor rotor 24, the motor The stator is fixed in the motor housing, the two ends of the motor main shaft are respectively provided with bearings 4, the outer ring of the bearings is connected with the motor housing, and the driving motor is provided with a motor cooling cavity 26 and a cooling exhaust pipe 27 ;

[0028] The first-stage compressor includes a first-stage compressor exhaust volute 11, a first-stage compressor impeller 12, and a first-stage turbine 13. The first-stage compressor impeller and the first-stage turbine rotate coaxially with the motor main shaft. The primary compressor is provided with a pr...

Embodiment 2

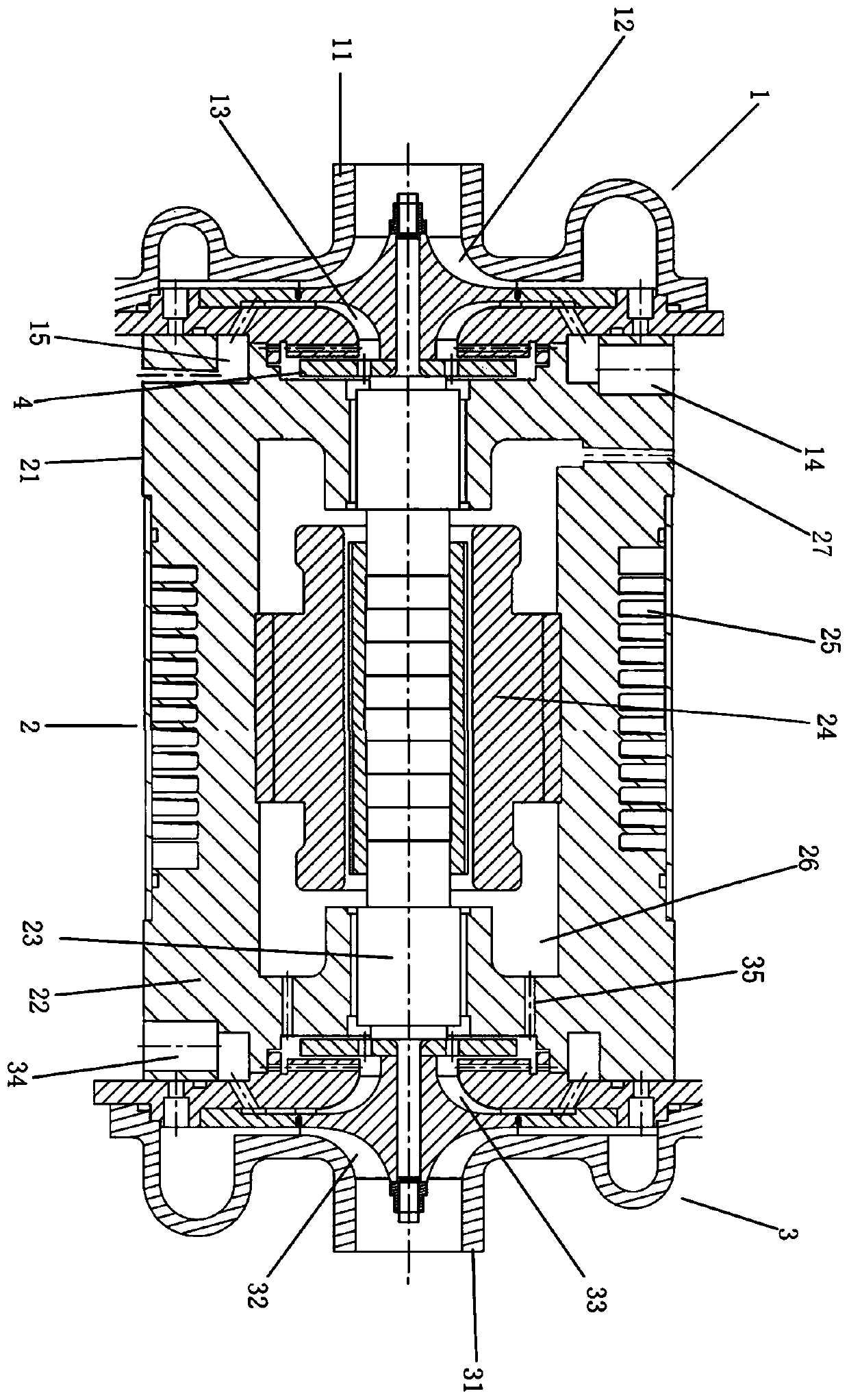

[0031] Such as figure 2 , Figure 4 as shown in

[0032] A two-stage hydrogen fuel cell stack gas supply device driven by a motor, including a drive motor 2, a first-stage compressor 1, a second-stage compressor 3 and an inter-stage communication pipeline, and the drive motor 2 includes a motor housing 21 , the motor stator 22, the motor main shaft 23 and the high-speed motor rotor 24, the motor stator is fixed in the motor housing, the two ends of the motor main shaft are respectively provided with bearings 4, and the outer ring of the bearing is connected with the motor housing, The drive motor is provided with a motor cooling cavity 26 and a cooling exhaust pipe 27; the first-stage compressor includes a first-stage compressor exhaust volute 11, a first-stage compressor impeller 12, and a first-stage turbine 13. The first-stage compressor impeller and the first-stage turbine rotate coaxially with the main shaft of the motor. The first-stage compressor is provided with a fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com