Preparing method of yolk thin and crispy chip

A production method and a technology for crisp chips, which are applied in the field of production of egg yolk chips, can solve the problems of high price and high cost, and achieve the effects of uniform shape, moderate hardness and crisp taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

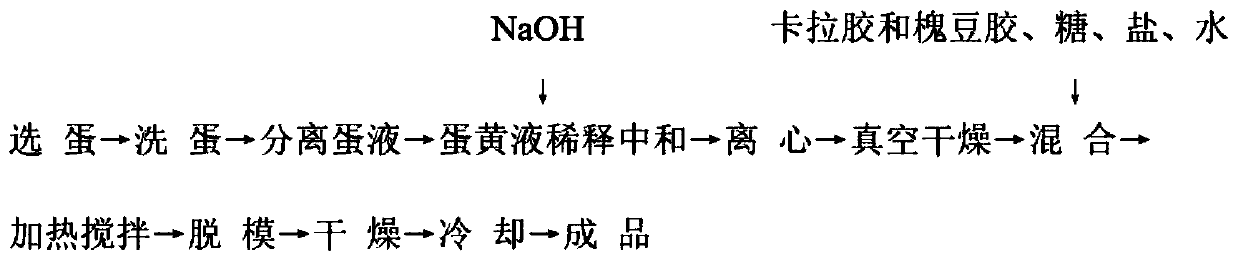

Method used

Image

Examples

Embodiment 1

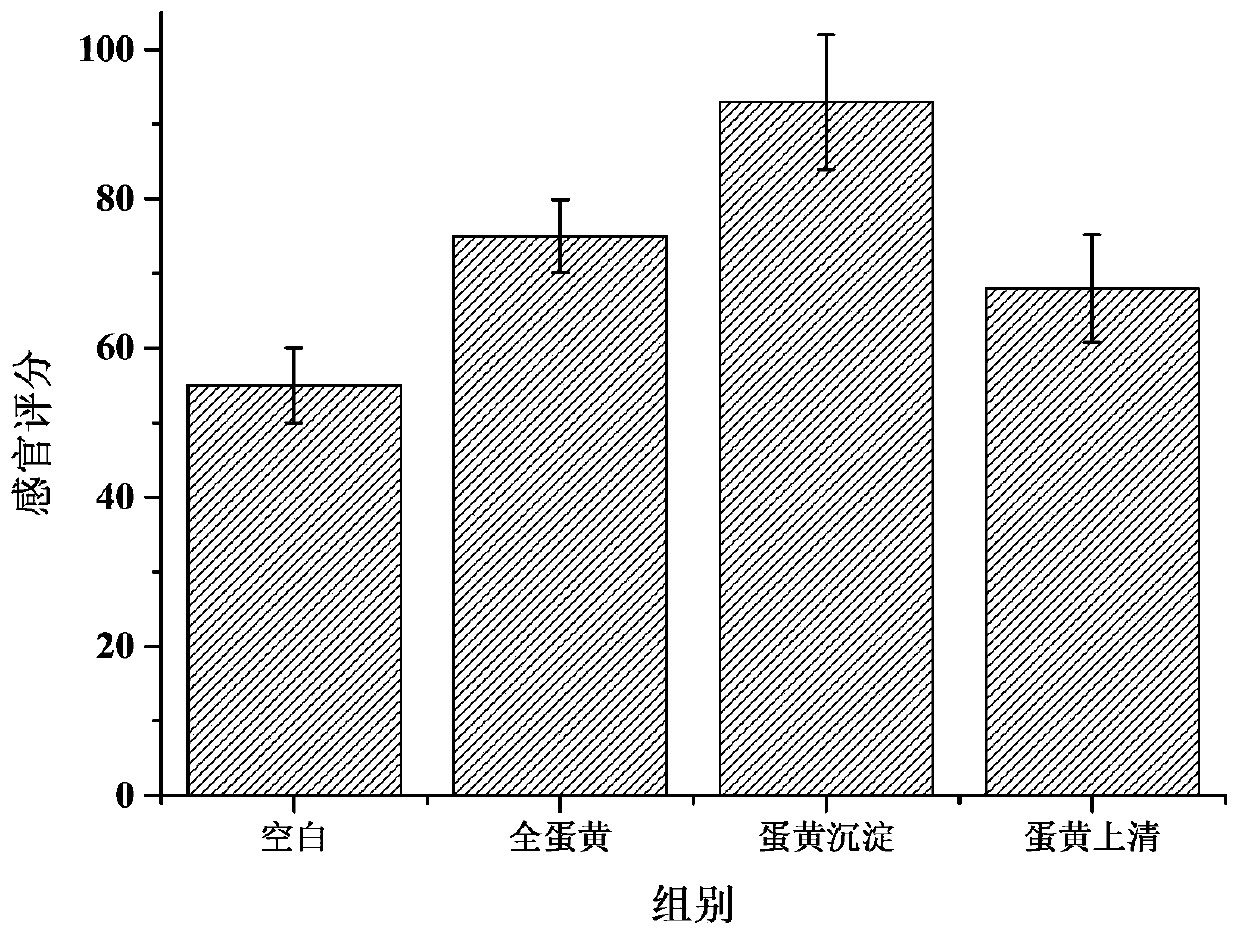

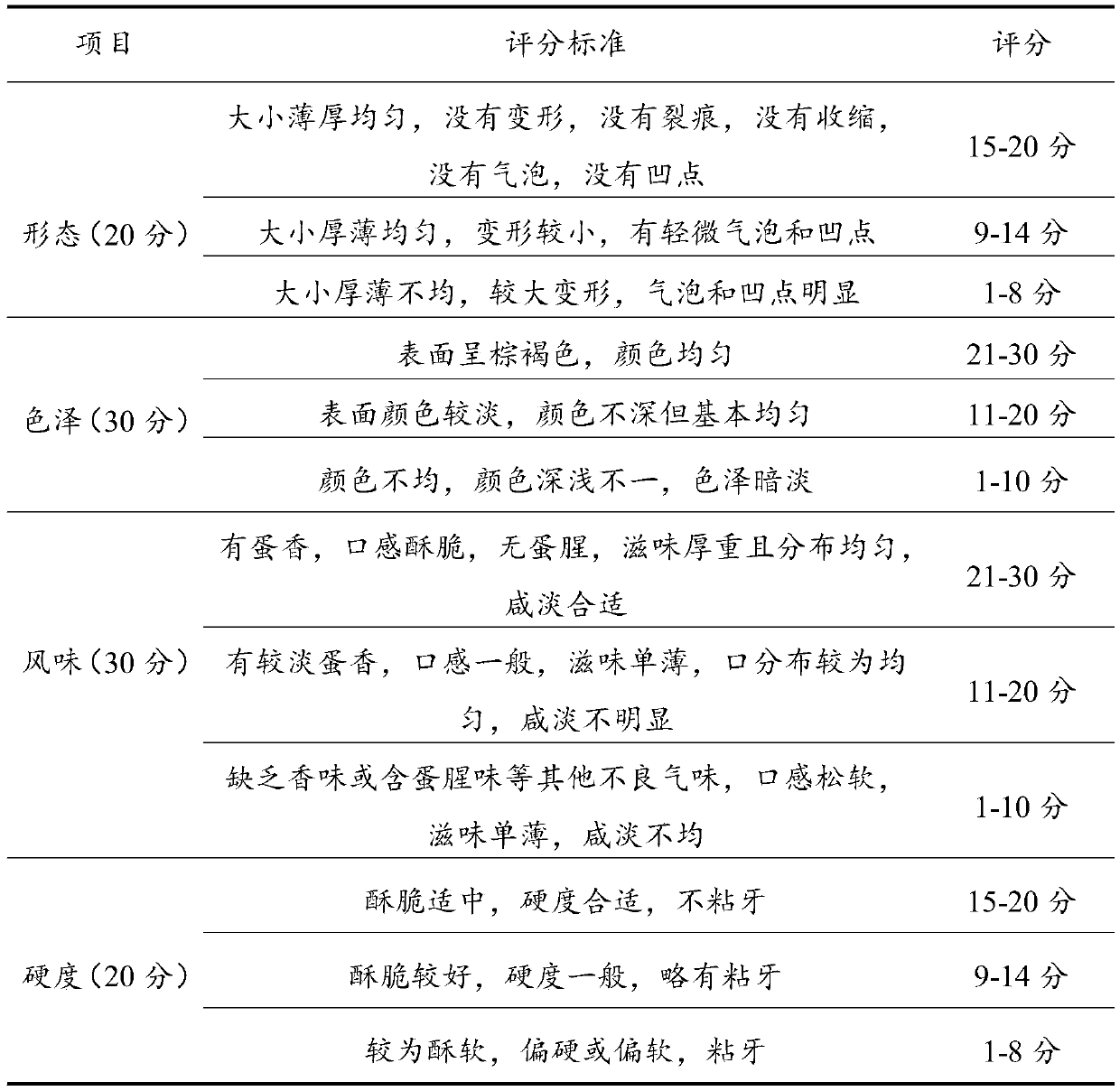

[0026] The influence of each component of embodiment 1 egg yolk on the quality of crispy egg yolk slices

[0027] (1) Select fresh eggs of moderate size, wash them, beat the eggs, separate the egg yolks and egg whites, remove the protein residues on the surface of the egg yolks and the yolk membrane, and obtain egg yolk liquid.

[0028] (2) Dilute the egg yolk liquid and distilled water at a volume ratio of 1:1.5, and stir at a constant speed; adjust the pH to 7 with 1mol / L NaOH, and stir evenly.

[0029] (3) Put the diluted and neutralized egg yolk into a centrifuge tube, centrifuge at 4°C for 45 minutes at 10,000rpm, and separate the supernatant and precipitate; put the centrifuged precipitate, supernatant and unseparated whole egg yolk at 55°C After vacuum drying for 12 hours, take it out and cool it down.

[0030] (4) Prepare 20g mixture with dried egg yolk precipitate 4.5%, carrageenan 2.5%, locust bean gum 1.5% and water 85.5%. In the blank group, egg yolk precipitate i...

Embodiment 2

[0034] (1) Select fresh duck eggs of moderate size, wash them, beat the eggs, separate the egg yolk and egg white, remove the protein residues on the surface of the egg yolk and the yolk membrane, and obtain the egg yolk liquid.

[0035] (2) Dilute the egg yolk liquid and distilled water at a volume ratio of 1:1.5, and stir at a constant speed; adjust the pH to 7 with 1mol / L NaOH, and stir evenly.

[0036] (3) Put the diluted and neutralized egg yolk liquid into a centrifuge tube, centrifuge at 4°C for 45min at 10,000rpm, separate the supernatant and precipitate; vacuum dry the centrifuged precipitate at 55°C for 12h, take it out, and cool it down.

[0037] (4) prepare 20g mixture with dried egg yolk precipitation 3.5%, carrageenan 1.5%, locust bean gum 0.5% and water 90.5%, pour it into a container, add 3% sugar and 1% salt to the mixture and stir well; The uniformly stirred mixture was put into a drying oven and heated at 105°C for 20 minutes, and stirred evenly when heated ...

Embodiment 3

[0041] (1) Select fresh goose eggs of moderate size, wash them, beat the eggs, separate the egg yolks and egg whites, remove the protein residues on the surface of the egg yolks and the yolk membrane, and obtain egg yolk liquid.

[0042] (2) Dilute the egg yolk liquid and distilled water at a volume ratio of 1:1.5, and stir at a constant speed; adjust the pH to 7 with 1mol / L NaOH, and stir evenly.

[0043] (3) Put the diluted and neutralized egg yolk liquid into a centrifuge tube, centrifuge at 4°C for 45min at 10,000rpm, separate the supernatant and precipitate; vacuum dry the centrifuged precipitate at 55°C for 12h, take it out, and cool it down.

[0044] (4) Use 5.5% of dried egg yolk precipitation, 3.5% of carrageenan, 2.5% of locust bean gum and 79.5% of water to prepare 20g of the mixture, pour it into a container, add 6% of sugar and 3% of salt into the mixture and stir well; Put the evenly stirred mixture into a drying oven and heat at 105°C for 20 minutes, and stir it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com