Cutting clamp and machining process of long blade for plastic pulverizer

A processing technology and pulverizer technology, applied in metal processing equipment, manufacturing tools, welding/cutting auxiliary equipment, etc., can solve the problems of high processing cost, difficult to adapt to different blade angles, easily damaged milling cutters, etc., and achieve high positioning accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

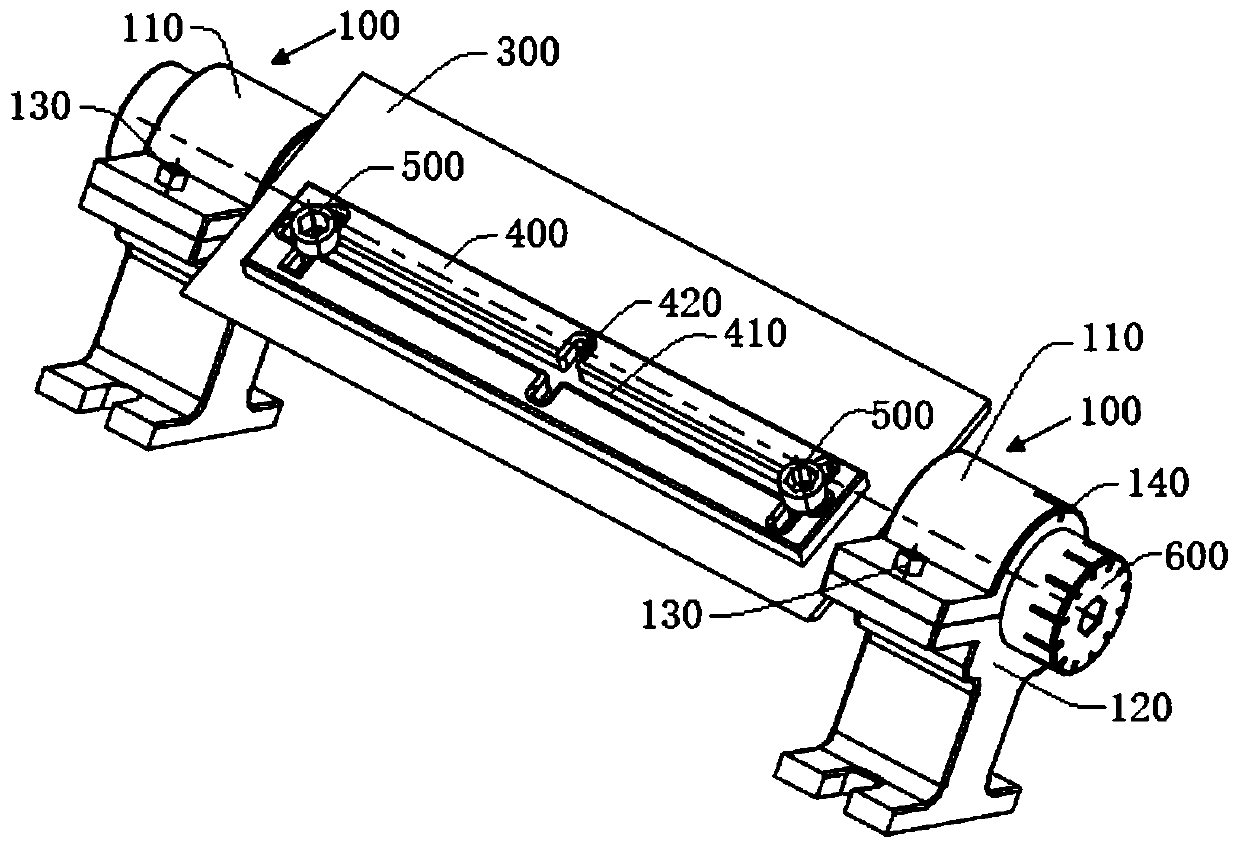

[0060] to combine image 3 and Figure 4 As shown, a long-blade cutting jig for a plastic pulverizer in this embodiment includes a base 100 , a rotating shaft 200 , a base plate 300 , a pressing plate 400 and a dial 600 . Among them, the base 100 is fixed on the workbench of the machine tool, and the middle position of the rotating shaft 200 is fixed to weld the substrate 300. When the base 100 rotates, the substrate 300 on it also rotates at the same angle, and the rotation angle of the rotating shaft 200 can be observed according to the dial 600; The space within is the clamping position 310 for the long blade blank 700 , and the long blade blank 700 is fixed on the substrate 300 through the pressing plate 400 . The structure and function of each part will be described in detail below.

[0061] to combine image 3 and Figure 4 As shown, the base 100 includes an upper fixing part 110 and a lower fixing part 120, and the upper fixing part 110 and the lower fixing part 12...

Embodiment 2

[0068] This embodiment is a processing technology of a long blade for a plastic pulverizer, wherein the cutting jig used is the cutting jig for a long blade for a plastic pulverizer in Example 1.

[0069] Specifically, a processing technology of long blades for plastic pulverizers, the steps are:

[0070] S1. Selection of raw materials: use No. 45 steel;

[0071] S2. Annealing: Place the selected No. 45 steel material in an annealing furnace for annealing treatment. The annealing temperature is 640°C, and the annealing time is 3.5h. Cool to 160°C in the annealing furnace, hold for 1h, and then air cool to room temperature;

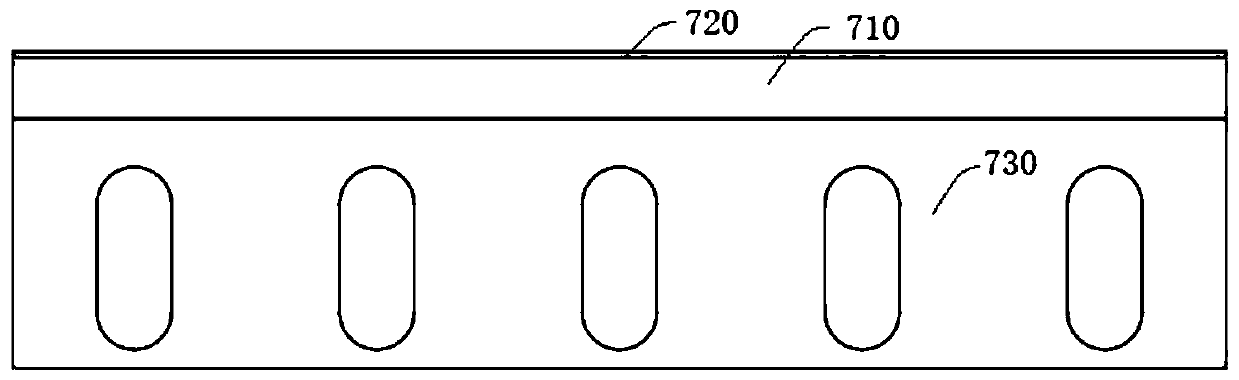

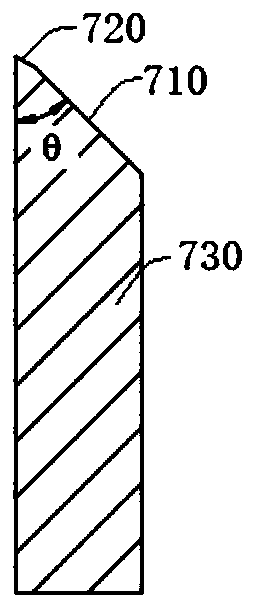

[0072] S3, preliminary processing: the material obtained by annealing is processed into a workpiece having the basic shape of the long blade body 730 except the first cutting edge surface 710 and the second cutting edge surface 720, leaving a margin of 1.5 mm on each surface;

[0073] S4. Flame cutting the first cutting edge surface 710: install the workp...

Embodiment 3

[0082] This embodiment is basically the same as Embodiment 2, except that: in step S4 of this embodiment, the cutting method of the flame cutting machine adopts intermittent cutting; parameters such as temperature and time in the process method are different.

[0083] Specifically, a processing technology of long blades for plastic pulverizers, the steps are:

[0084] S1. Selection of raw materials: 42CrMo steel is used;

[0085] S2, annealing: place the selected 42CrMo steel in an annealing furnace for annealing treatment, the annealing temperature is 710°C, the annealing time is 225min, cool to 180°C in the annealing furnace, keep warm for 1.5h, then air cool to room temperature;

[0086] S3, preliminary processing: the material obtained by annealing is processed into a workpiece having the basic shape of the long blade body 730 except the first cutting edge surface 710 and the second cutting edge surface 720, leaving a margin of 1.5 mm on each surface;

[0087] S4. Flame c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Deformation | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com