Production equipment for PVC films

A technology of PVC film and production equipment, applied in the field of production equipment of PVC film, can solve the problems of incapable of stacking, less storage, more workshop space, etc., to ensure speed and quality, prevent bridging phenomenon, and increase storage quantity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

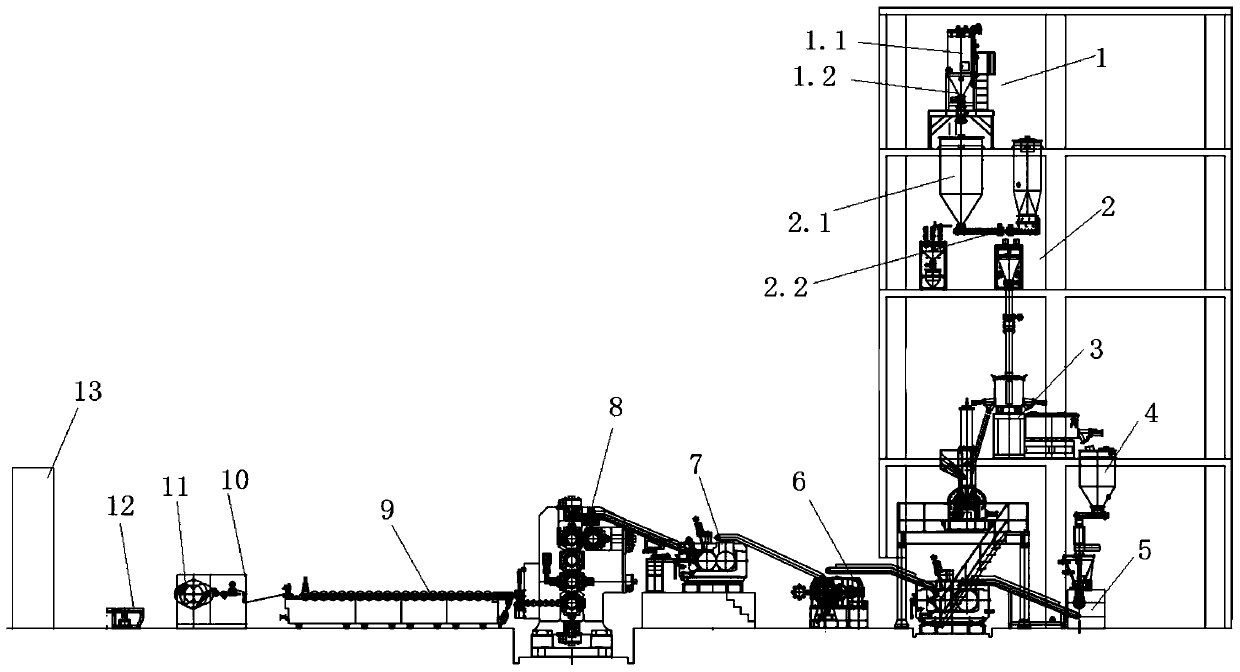

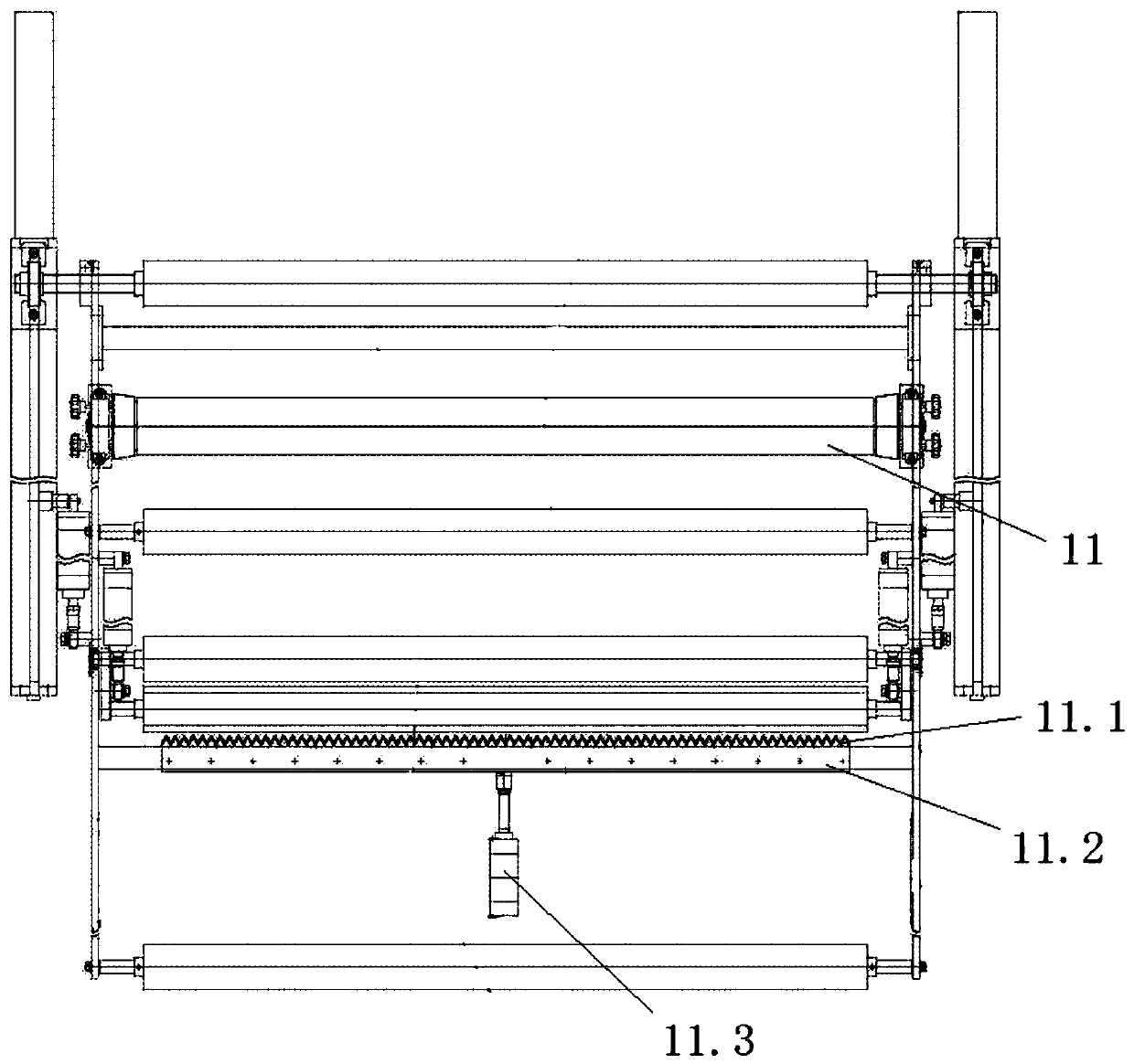

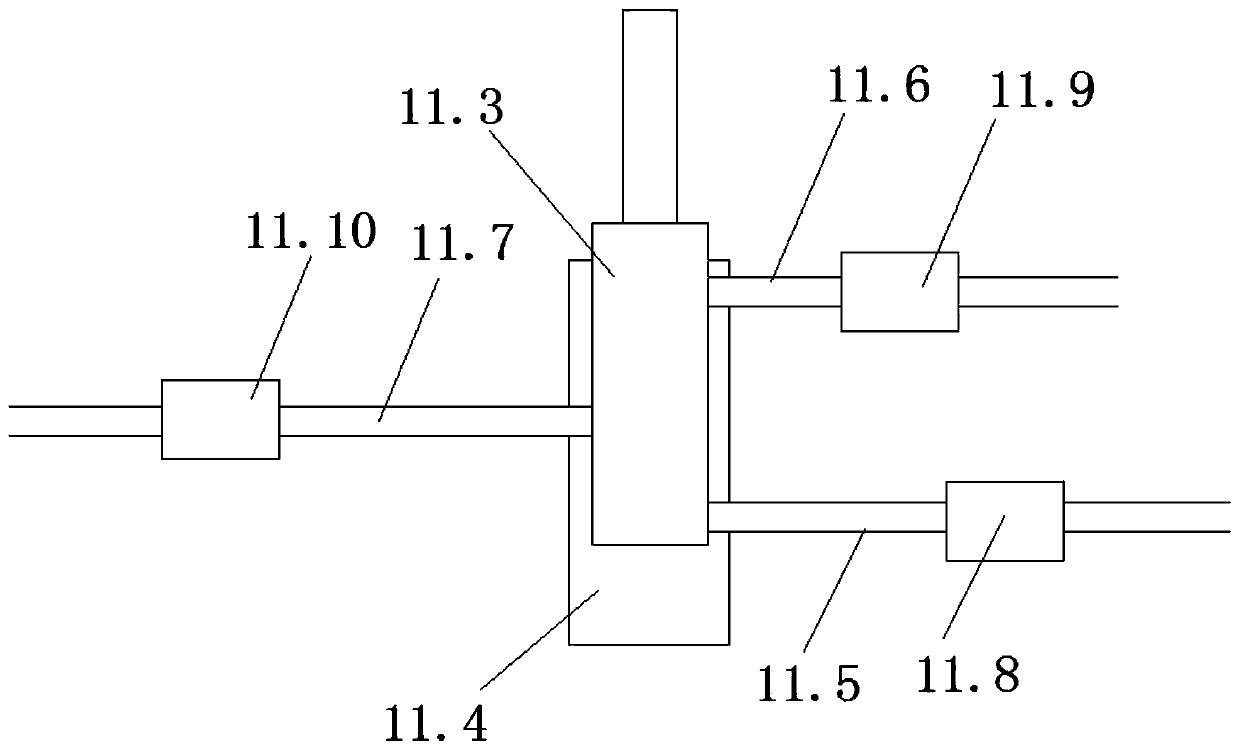

[0033] see Figure 1 to Figure 4 , the present invention relates to a kind of production equipment of PVC film, comprises material mixing system 1, material mixing system 1, automatic metering system 2, high-speed mixer 3, low-speed mixer 4, planetary extruder 5, filter extruder 6, roll mill 7. Calender 8, cooling roll group 9, coiler 10, cutting device 11, weighing platform 12 and storage rack 13.

[0034] The mixing system 1 is provided with a plurality of feeding bins 1.1, and the feeding bins 1.1 add PVC powder, plasticizers, heat stabilizers, lubricants, flame retardants, anti-ultraviolet rays, etc. to the inside through the feeding system and feeding pipes 1.2. The bottom discharge pipe of the mixing system 1 is connected to the automatic metering system 2, the automatic metering system 2 has a mixing hopper 2.1, and the bottom of the mixing hopper 2.1 is equipped with a weighing system 2.2, weighing After the weight system 2.2 weighs, the material is sent to the high-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com