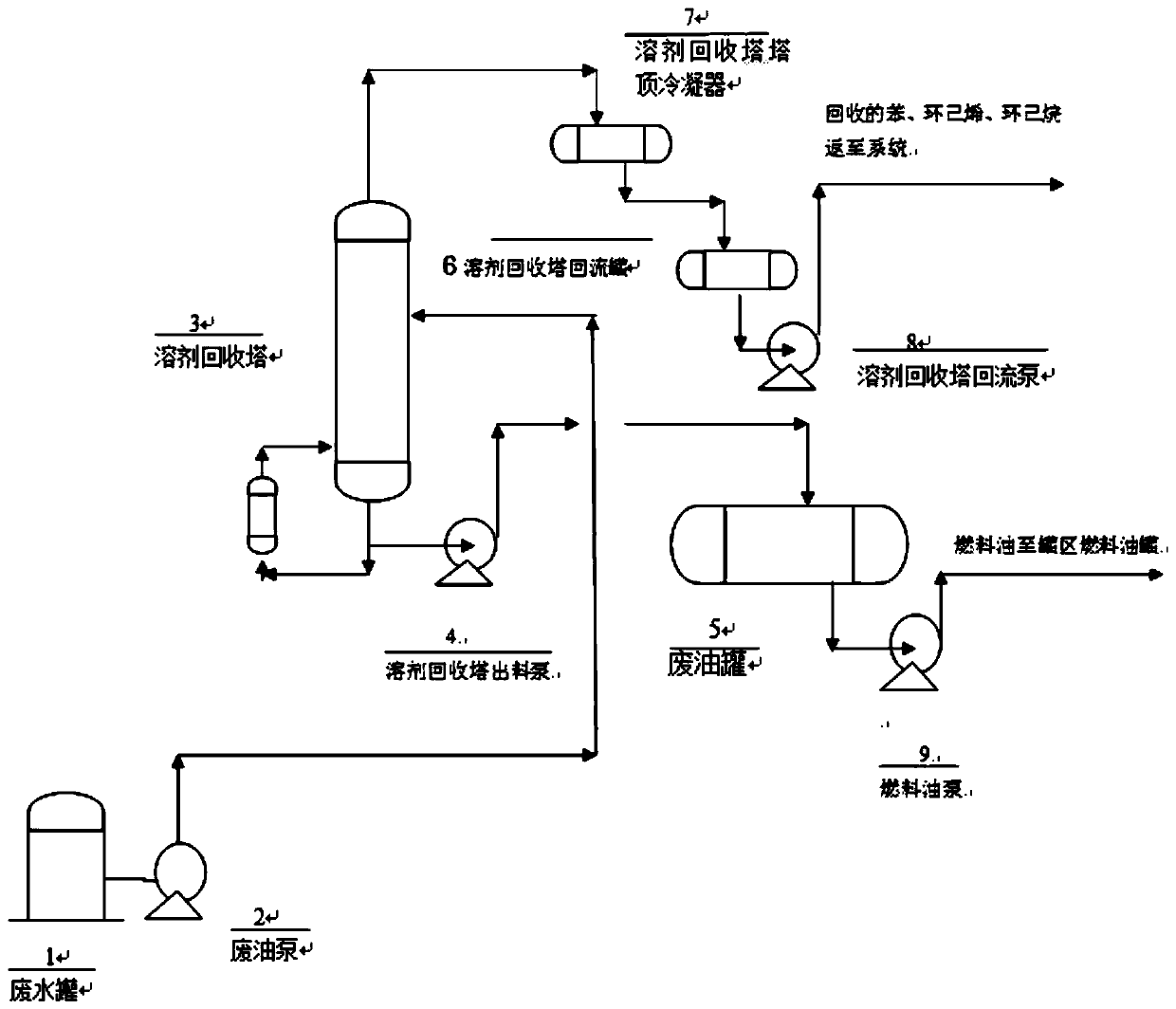

Fuel oil recovery process

A fuel oil and recovery system technology, applied in the preparation of organic compounds, hydrocarbons, organic chemistry, etc., can solve the problems of inability to recover alkanols and ketones, waste resources, and discharge to waste water tanks, etc., and reduce the discharge of hazardous waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

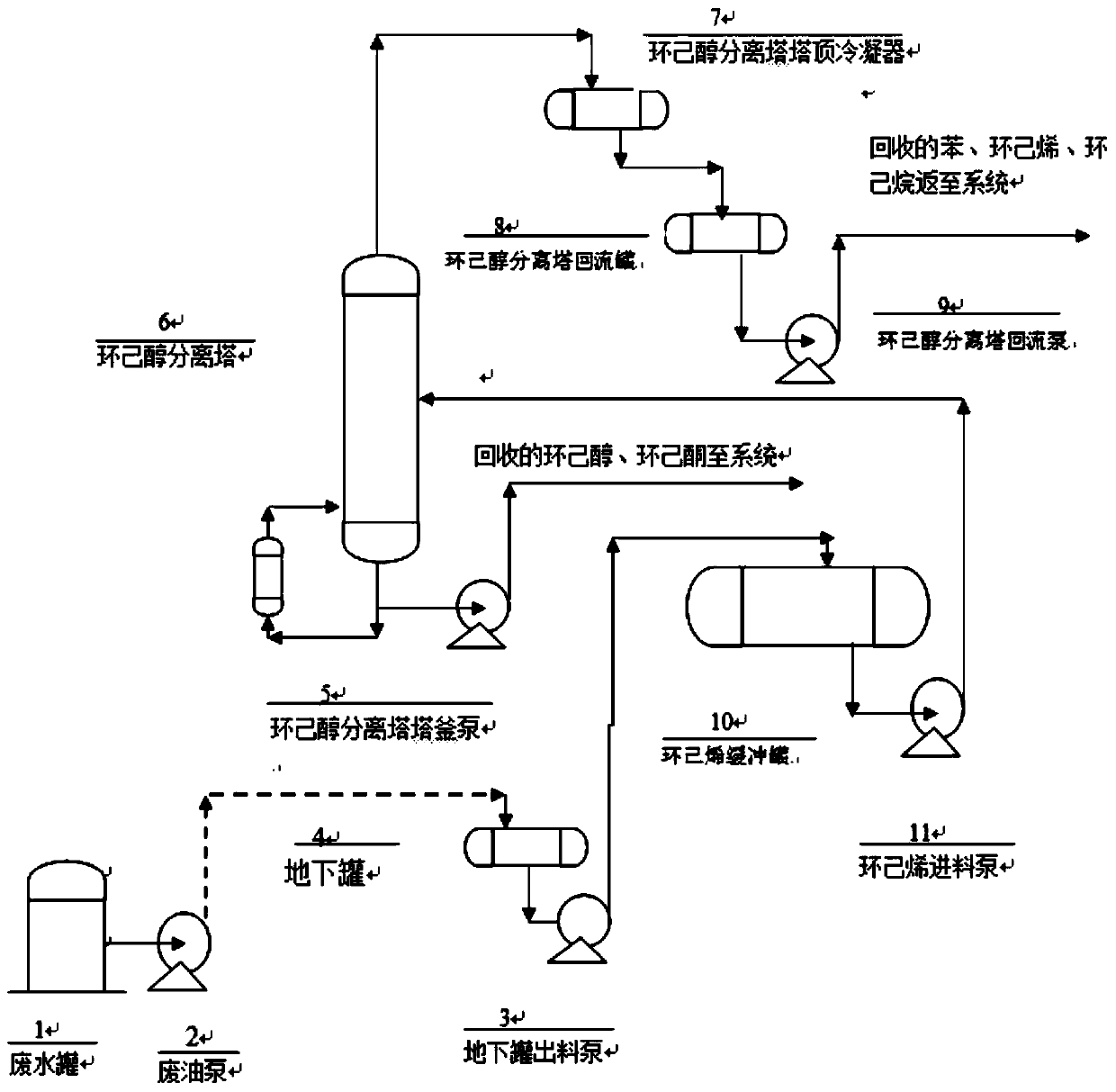

Embodiment 1

[0046] A pipeline is arranged between the waste oil pump 1 and the underground tank 4, and the waste oil and oily waste water recovered by the system is refined and stratified by the waste oil tank 1, and then transported to the underground tank 4 by the waste oil pump 2, and transported by the underground pump 3 In the cyclohexene buffer tank 10, the cyclohexanol separation tower feed pump 11 is transported to the cyclohexanol separation tower 6 by the cyclohexanol separation tower 6 inlet pipeline, and the effect of the cyclohexanol separation tower 6 is to remove waste oil The cyclohexanol contained in the heavy component enters the bottom of the cyclohexanol separation tower 6, and is separated and recycled after entering the refining system through the tower pump. The benzene, cyclohexene, and cyclohexane in the light component are separated by cyclohexanol After being condensed by the cyclohexanol separation tower condenser 7 at the top of the tower 6, it is recycled to t...

Embodiment 2

[0056] A fuel oil recovery system, comprising: waste water tank 1, waste oil pump 2, underground tank 4, underground pump 3, cyclohexene buffer tank 10, cyclohexene feed pump 11, cyclohexanol separation tower 6, condenser 7 , cyclohexanol separation tower reflux tank 8, cyclohexanol separation tower reflux pump 9, the waste water tank 1, waste oil pump 2, underground tank 4, underground pump 3, cyclohexene buffer tank 10, cyclohexene feed pump 11, cyclohexanol separation tower 6 is connected successively, and the tower top outlet of described cyclohexanol separation tower 6 is connected with condenser 7, and described condenser 7 is connected with cyclohexanol separation tower reflux tank 8, cyclohexanol separation tower reflux The pump 9 is connected; the bottom outlet of the cyclohexanol separation tower 6 is connected with the cyclohexanol and cyclohexanone recovery system through the cyclohexanol separation tower bottom pump 5.

[0057] The cyclohexanol separation tower 6 ...

Embodiment 3

[0059] A fuel oil recovery system, comprising: waste water tank 1, waste oil pump 2, underground tank 4, underground pump 3, cyclohexene buffer tank 10, cyclohexene feed pump 11, cyclohexanol separation tower 6, condenser 7 , cyclohexanol separation tower reflux tank 8, cyclohexanol separation tower reflux pump 9, the waste water tank 1, waste oil pump 2, underground tank 4, underground pump 3, cyclohexene buffer tank 10, cyclohexene feed pump 11, cyclohexanol separation tower 6 is connected successively, and the tower top outlet of described cyclohexanol separation tower 6 is connected with condenser 7, and described condenser 7 is connected with cyclohexanol separation tower reflux tank 8, cyclohexanol separation tower reflux The pump 9 is connected; the bottom outlet of the cyclohexanol separation tower 6 is connected with the cyclohexanol and cyclohexanone recovery system through the cyclohexanol separation tower bottom pump 5.

[0060] Waste oil and oily waste water are r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com