Preparation method of amino-terminated hyperbranched aliphatic polyester and application thereof

An amino-terminated hyperbranched and aliphatic polyester technology is applied in the preparation of amino-terminated hyperbranched aliphatic polyesters, and in the field of preparation of amino-terminated hyperbranched polyesters, and can solve the problems of high energy consumption, unfavorable industrial production, long time, etc. problem, to achieve the effect of good reactivity, increased hardness and good tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

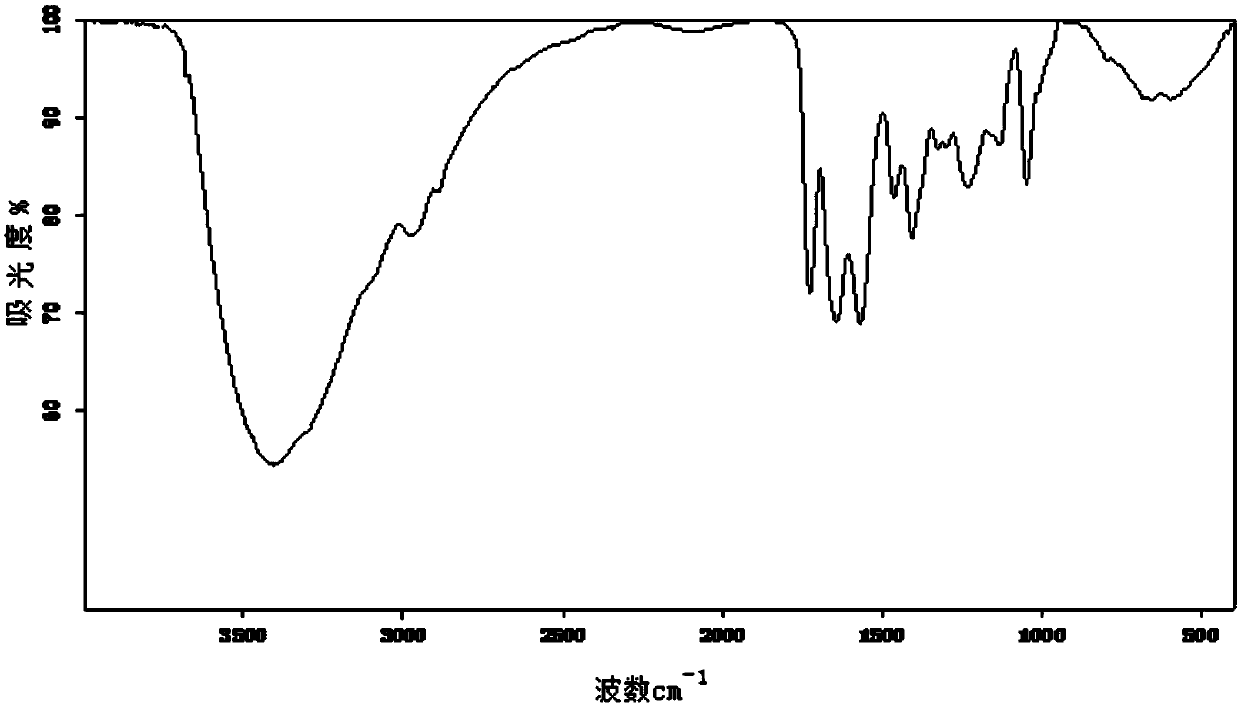

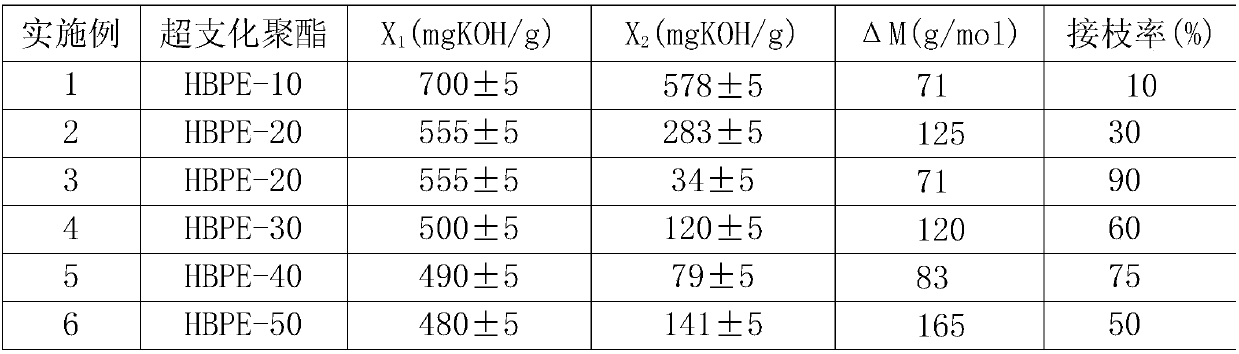

[0025] Get the hyperbranched polyester (marked as HBPE-10) 2.00g and 0.182g of hyperbranched polyester (marked as HBPE-10) with 8 terminal hydroxyl numbers and join in the reaction vessel, the temperature is raised to 80 degrees Celsius, and 1% of Catalyst, reacted for 3 hours, cooled for 1 hour, and discharged to obtain an amino-terminated hyperbranched polyester with a graft rate of 10%. From the infrared spectrum, it can be seen that at 2931cm -1 and 2855cm -1 The peak at is the corresponding absorption peak of the amino group of the product obtained after modification of the terminal amino group.

Embodiment 2

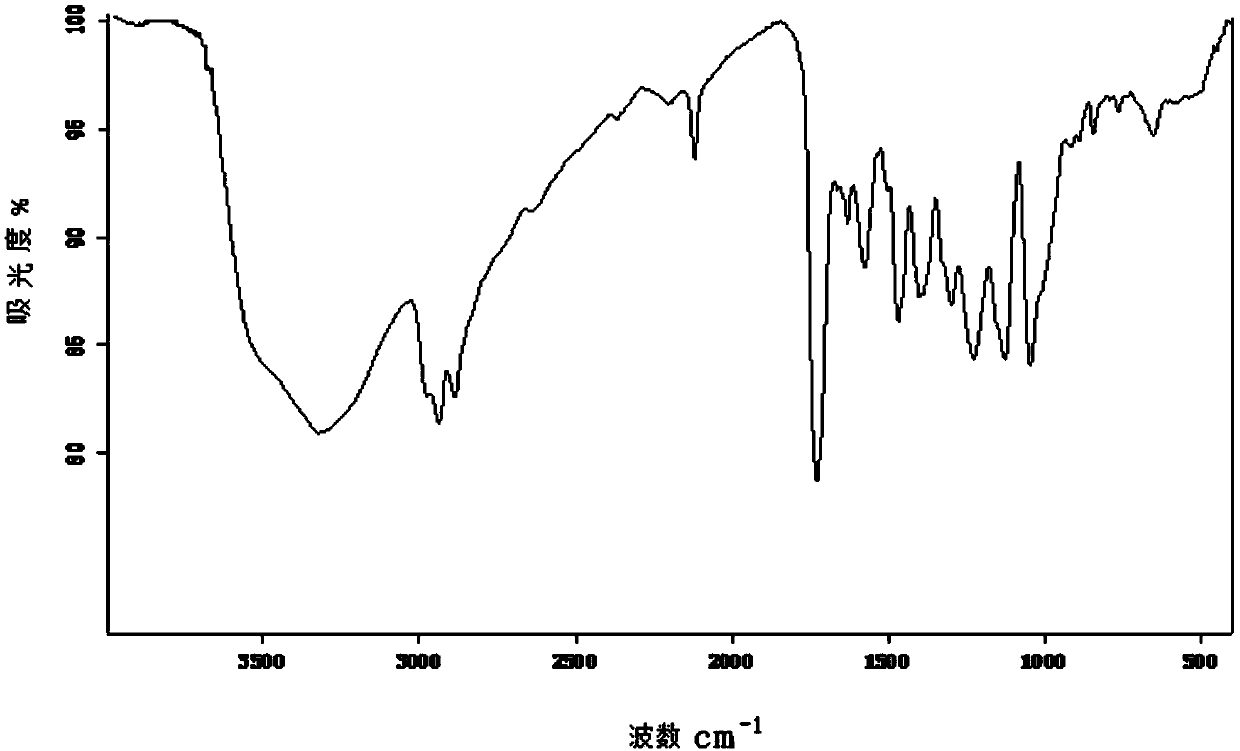

[0027] Get 2.00g of hyperbranched polyester (marked as HBPE-20) and 0.762g of hyperbranched polyester (marked as HBPE-20) with 16 hydroxyl groups and join in the reaction vessel, heat up to 120 degrees Celsius, add 0.5 % catalyst, reacted for 4h, cooled for 1h, and discharged to obtain an amino-terminated hyperbranched polyester with a grafting rate of 30%.

Embodiment 3

[0029] Get the hyperbranched polyester (marked as HBPE-20) 2.00g and 2.42g of hyperbranched polyester (marked as HBPE-20) with 16 terminal hydroxyl numbers and join in the reaction vessel (feeding ratio 100%), heat up to 180 degrees Celsius, add 0.5% Catalyst, reacted for 10 hours, cooled for 1 hour, and discharged to obtain amino-terminated hyperbranched polyester with a graft rate of 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com