Production process of cotton-wool-blended yarn-dyed fabric

A technology of wool blending and production technology, which is applied in the direction of textile, fabric elongation, textiles and papermaking, etc. It can solve the problems of not washing in the washing machine, poor pilling and shrinkage, etc., and achieves soft hand feeling, light and thin texture, and thermal performance excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

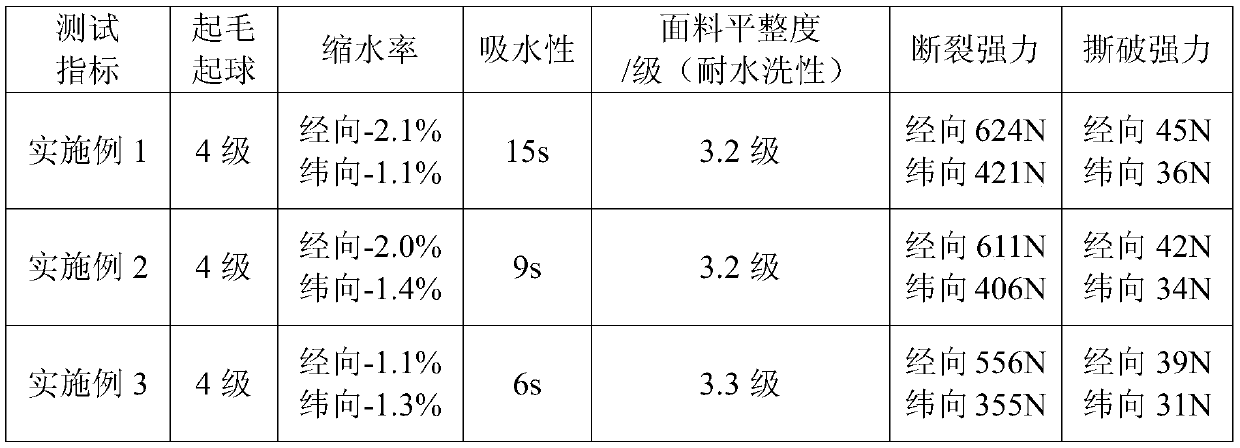

Examples

Embodiment 1

[0015] vertical Density: 120 threads / inch, yarn count: 40 British count single yarn, composition: cotton 70%, wool 30% Latitude Density: 90 threads / inch, yarn count: 40 British count single yarn, composition: cotton 70%, wool 30% organizational structure 2 / 2 broken oblique color Blue Gray Black Multicolor Plaid

[0016] The specific steps are:

[0017] The production process is spinning → dyeing → sizing → weaving → singeing → desizing → liquid ammonia → pre-stenter → sanding → sanding → tenter → pre-shrinking. Among them, the singeing speed is 95m / min, the singeing method adopts cutting and burning, and the flame intensity is 10 mbar; the liquid ammonia speed is 30m / min; the sanding speed is 15m / min, the large cylinder speed is 20r / min, and the tension is 200N; In the pre-stenter process, the concentration of the fatty acid softener RQR in the roll groove is 15g / L, and the pre-stenter temperature is 120°C; The concentration of RQR is 10g / L...

Embodiment 2

[0019] vertical Density: 140 threads / inch, Yarn count: 50 English plied yarn, Composition: Cotton 80%, Wool 20% Latitude Density: 90 threads / inch, Yarn count: 50 English plied yarn, Composition: Cotton 80%, Wool 20% organizational structure 2 / 2 twill color Red, white and gray multicolor plaid

[0020] The specific steps are:

[0021] The production process is spinning → dyeing → sizing → weaving → singeing → desizing → liquid ammonia → pre-stenter → sanding → sanding → tenter → pre-shrinking. Among them, the singeing speed is 90m / min, the singeing method adopts direct burning, and the flame intensity is 8 millibars; the liquid ammonia speed is 25m / min; the sanding speed is 20m / min, the large cylinder speed is 25r / min, and the tension is 250N; In the pre-stenter process, the concentration of the fatty acid softener RQR in the roll groove is 10g / L, and the pre-stenter temperature is 130°C; The concentration of RQR is 20g / L, the moisture conte...

Embodiment 3

[0023] vertical Density: 150 threads / inch, Yarn count: 60 British count plied yarn, Composition: Cotton 85%, Wool 15% Latitude Density: 100 pcs / inch, Yarn count: 60 English plied yarn, Composition: Cotton 85%, Wool 15% organizational structure 3 / 1 twill color Warp White Latitude Blue

[0024] The specific steps are:

[0025] The production process is spinning → dyeing → sizing → weaving → singeing → desizing → liquid ammonia → pre-stenter → sanding → sanding → tenter → pre-shrinking. Among them, the singeing speed is 105m / min, the singeing method adopts cutting and burning, and the flame intensity is 12 mbar; the speed of liquid ammonia is 20m / min; In the pre-stenter process, the concentration of the fatty acid softener RQR in the roll groove is 5g / L, and the pre-stenter temperature is 135°C; The concentration of RQR is 5g / L, the moisture content of the drop cloth is 6%, the tentering temperature is 135°C, and other processes are convention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com