Ground testing and adjusting device for separate injection of CO2 by double pipes and application method thereof

A ground and pipeline technology, applied in the field of double-pipe CO2 injection ground measurement and adjustment device, to achieve the effects of small erosion damage, long-term accuracy, and multiple stages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

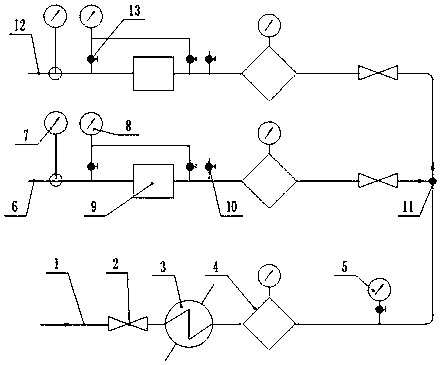

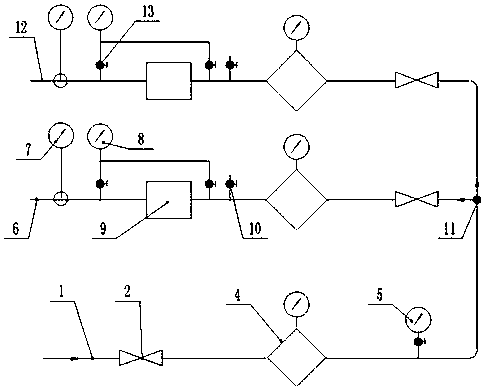

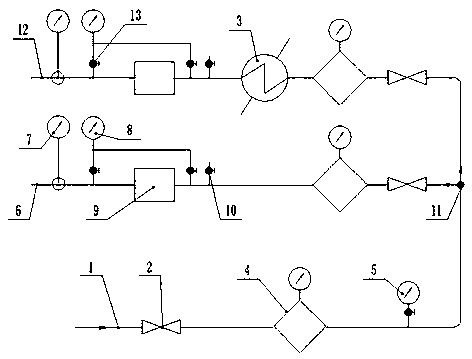

[0035] See figure 1 As shown, double-pipe injection of CO 2 The ground measurement and adjustment device, the tee 11 is respectively connected to the main pipeline 1, the sub-pipeline 1 6 and the sub-pipeline 2 12, the main pipeline is connected to the valve 2, the flow meter 4 and the pressure gauge 5, and the sub-pipeline 1 and the sub-pipeline 2 are connected to the valve And flowmeter, adjustable pressure reducer 9, differential pressure gauge 8, thermometer 7 and vent valve 10 are also installed on branch line one and branch line two, and thermometer 7 is installed after adjustable pressure reducer 9. This device is configured for CO 2 The pipeline pressure is high, so it is necessary to depressurize in two ways and then inject gas. In order to facilitate disassembly and assembly, as shown in the figure, a needle valve 13 is generally installed between the pressure gauge and the pipeline. Since the differential pressure gauge has two pressure pipelines connected before ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com