A device and method for testing the separation performance of aircraft external stores in a high-speed wind tunnel

A high-speed wind tunnel and separation performance technology, which is applied in the field of high-speed wind tunnel experiments and flight mechanics, can solve the problems of difficult installation and adjustment, increase the degree of blockage of the wind tunnel, and reduce the degree of blockage of the wind tunnel. The effect of clogging degree and clogging degree reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

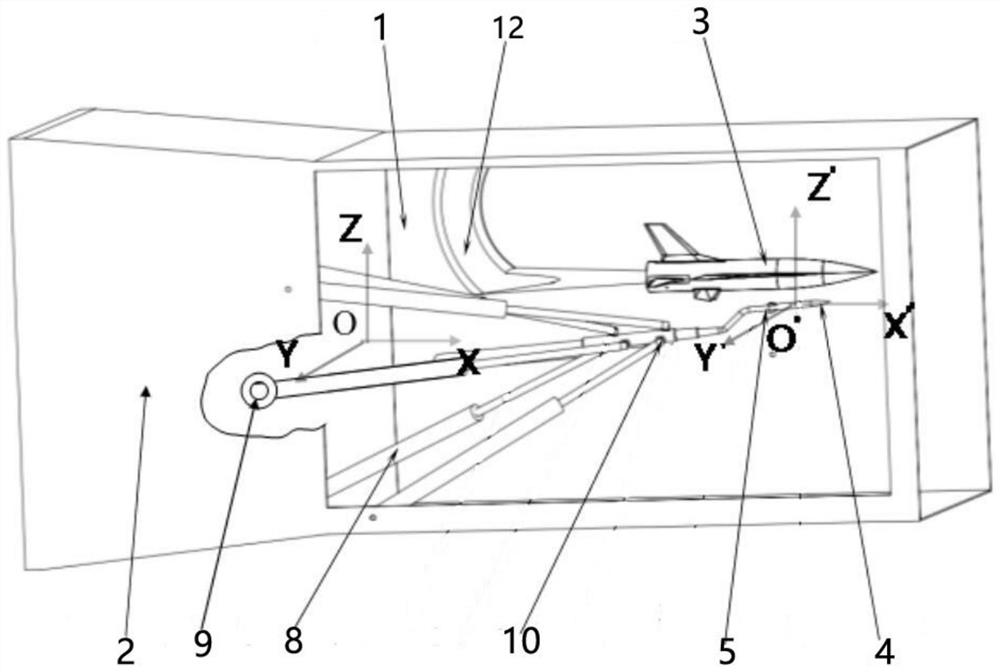

[0072] In order to clearly illustrate the technical features of this solution, the specific implementation of the present invention will be further described below according to the accompanying drawings.

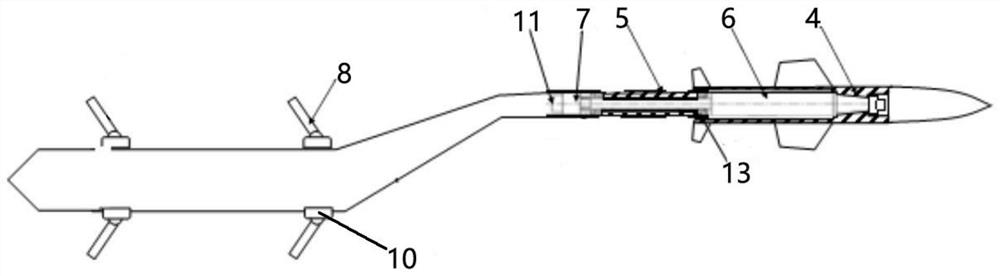

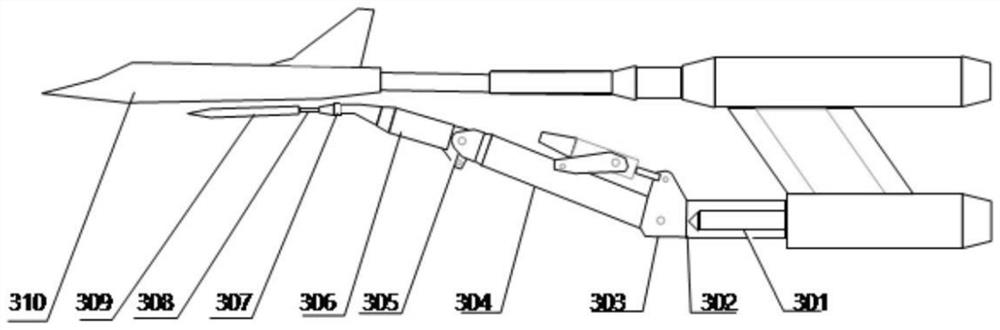

[0073] Such as figure 1 and figure 2 As shown, a device for testing the separation performance of aircraft external stores in a high-speed wind tunnel, including a wind tunnel experiment section 1, a wind tunnel diffusion section 2, a parent aircraft model 3, an external store model 4, a tail strut 5, a digital displacement cylinder 8, Multi-component balance 6, rolling drive device 7, rolling measuring device 11 and position measuring device.

[0074] The parent aircraft model 3 is an aircraft model that carries the external store model 4 and is used to test the separation performance of the external store model 4. The parent aircraft model 3 is installed inside the wind tunnel test section 1 through the variable angle of attack device 12. The variable angle of attack de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com