Preparation and application of hydrogen sensing material

A technology for sensing materials and hydrogen, which is applied to the analysis of materials, material resistance, and material analysis through electromagnetic means. It can solve problems such as short service life, poor selectivity, and poor stability, and achieve good stability and gas selectivity. Solve the effect of low hydrogen selection sensitivity and good hydrogen sensing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

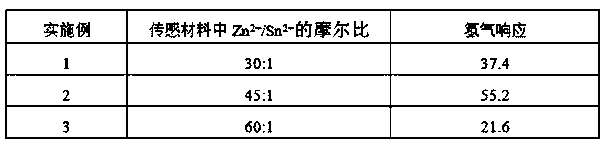

Embodiment 1

[0021] A preparation of a hydrogen detection material, comprising the following steps:

[0022] Step 1, Zn 2+ / Sn 2+ SnO with a molar ratio of 30:1 2 Preparation of Doped Core-Shell ZnO Microsphere Precursor

[0023] 0.021g of zinc oxide (ZnO) was redispersed in 27mL of ethanol solution, stirred magnetically for 10min, then ultrasonicated for 10min, and then stirred for 10min to form a uniform dispersion, then added 20mg of PVP, stirred magnetically for 20min, as solution A. 0.038g SnCl 2 2H 2 O was dissolved in 60mL of ethanol, stirred magnetically for 10min, then measured 3mL of the solution and added dropwise to solution A during stirring, and continued magnetically stirred for 20min. The mixed solution was transferred to a 50mL reactor, reacted in an oven at 120°C for 24h, and then the reaction product was centrifuged and washed three times with ethanol and water respectively, and then dried in an oven at 80°C for 20h to obtain a light yellow powder.

[0024] Step 2,...

Embodiment 2

[0027] A preparation of a hydrogen detection material, comprising the following steps:

[0028] Step 1, Zn 2+ / Sn 2+ SnO with a molar ratio of 45:1 2 Preparation of Doped Core-Shell ZnO Microsphere Precursor

[0029] 0.021g of zinc oxide (ZnO) was redispersed in 27mL of ethanol solution, stirred magnetically for 10min, then ultrasonicated for 10min, and then stirred for 10min to form a uniform dispersion, then added 20mg of PVP, stirred magnetically for 20min, as solution A. 0.026g SnCl 2 2H 2 O was dissolved in 60mL of ethanol, stirred magnetically for 10min, then measured 3mL of the solution and added dropwise to solution A during stirring, and continued magnetically stirred for 20min. The mixed solution was transferred to a 50mL reactor, reacted in an oven at 120°C for 24h, and then the reaction product was centrifuged and washed three times with ethanol and water respectively, and then dried in an oven at 80°C for 20h to obtain a light yellow powder.

[0030] Step 2,...

Embodiment 3

[0033] A preparation of a hydrogen detection material, comprising the following steps:

[0034] Step 1, Zn 2+ / Sn 2+ SnO with a molar ratio of 60:1 2 Preparation of Doped Core-Shell ZnO Microsphere Precursor

[0035] 0.021g of zinc oxide (ZnO) was redispersed in 27mL of ethanol solution, stirred magnetically for 10min, then ultrasonicated for 10min, and then stirred for 10min to form a uniform dispersion, then added 20mg of PVP, stirred magnetically for 20min, as solution A. 0.018g SnCl 2 2H 2 O was dissolved in 60mL of ethanol, stirred magnetically for 10min, then measured 3mL of the solution and added dropwise to solution A during stirring, and continued magnetically stirred for 20min. The mixed solution was transferred to a 50mL reactor, reacted in an oven at 120°C for 24h, and then the reaction product was centrifuged and washed three times with ethanol and water respectively, and then dried in an oven at 80°C for 20h to obtain a light yellow powder.

[0036] Step 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com