Preparation method of fluorocarbon polymer-modified chemical conversion graphene/zinc oxide thin film-shaped multiband light sensing device

A zinc oxide film, fluorocarbon polymer technology, applied in graphene, scientific instruments, material analysis by optical means, etc. The effect of large noise ratio, convenient and fast preparation process, and low detection limit of light intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) At room temperature, weigh 300 mg of graphene oxide, place it in a 200 mL beaker, then add 100 mL of distilled water to form a dispersion with a concentration of 3 mg / mL, and then process it with an ultrasonic instrument for 10 hours to obtain 100 mL of a graphene oxide dispersion; Measure 10 mL of the graphene oxide dispersion each time and pour it into a sand core funnel with a diameter of 4.5 cm for suction filtration for 3 days to obtain a graphene oxide film.

[0037] (2) Put the graphene oxide film in the step (1) in a glass petri dish, add 20mL of 55% hydroiodic acid, seal the petri dish with the film, and place it in a dark place. After 2h, take out the film and wash it with 95% The rGO film was obtained after soaking and washing with ethanol for 3 times and drying.

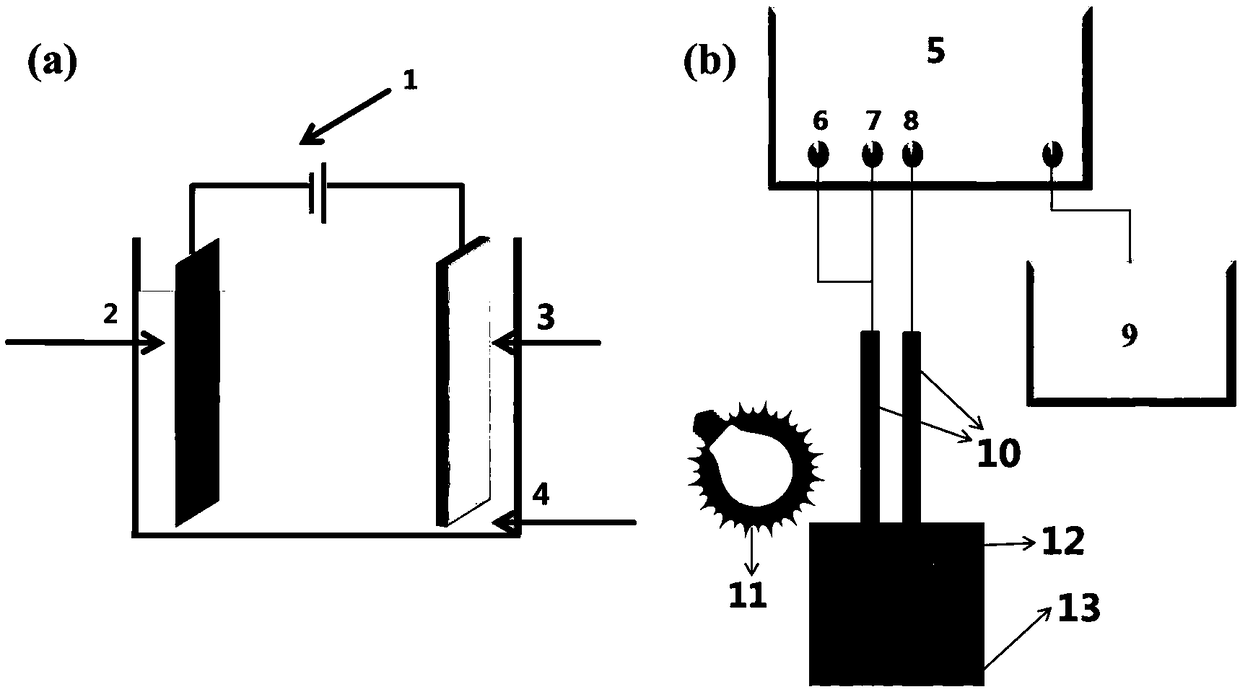

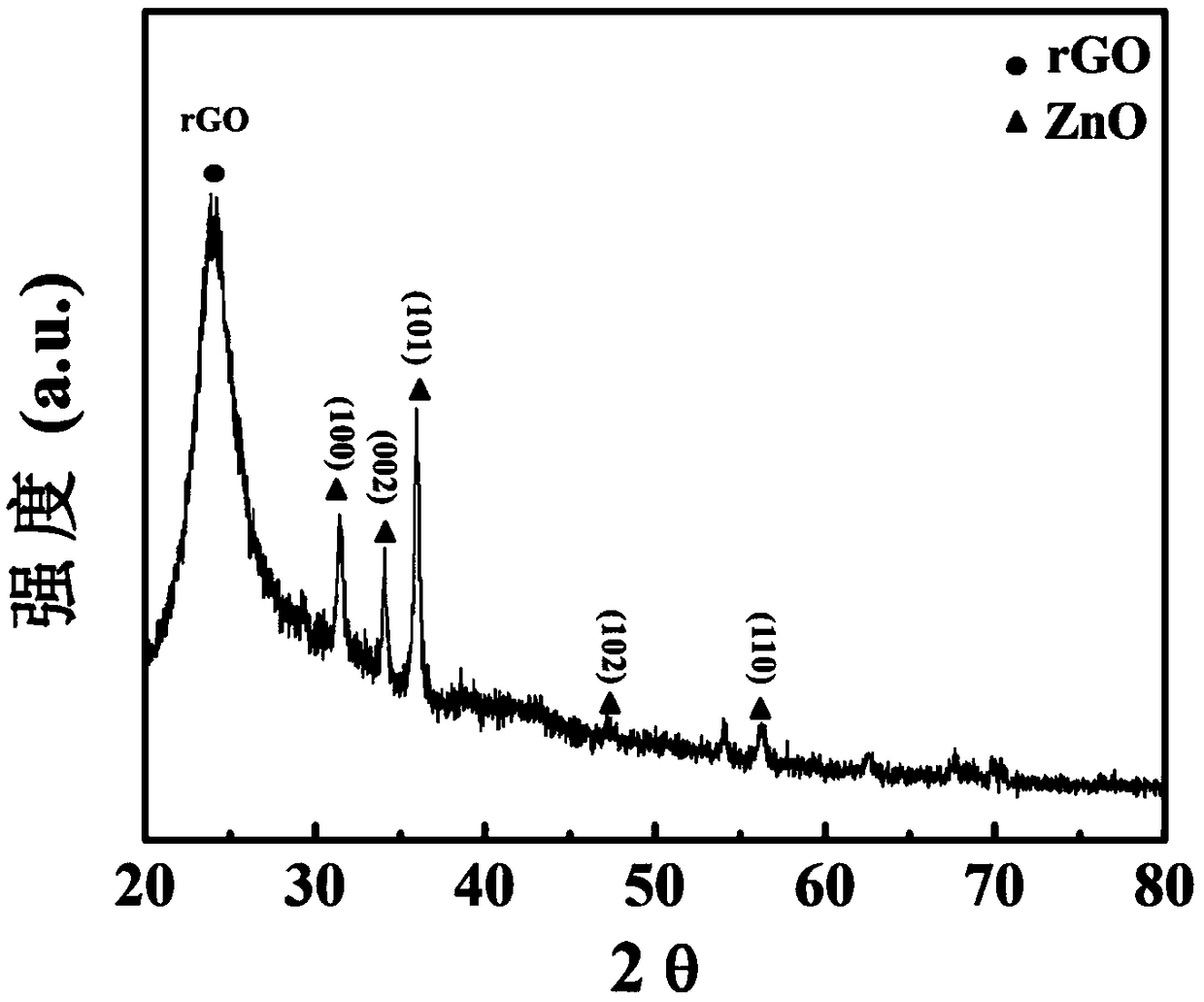

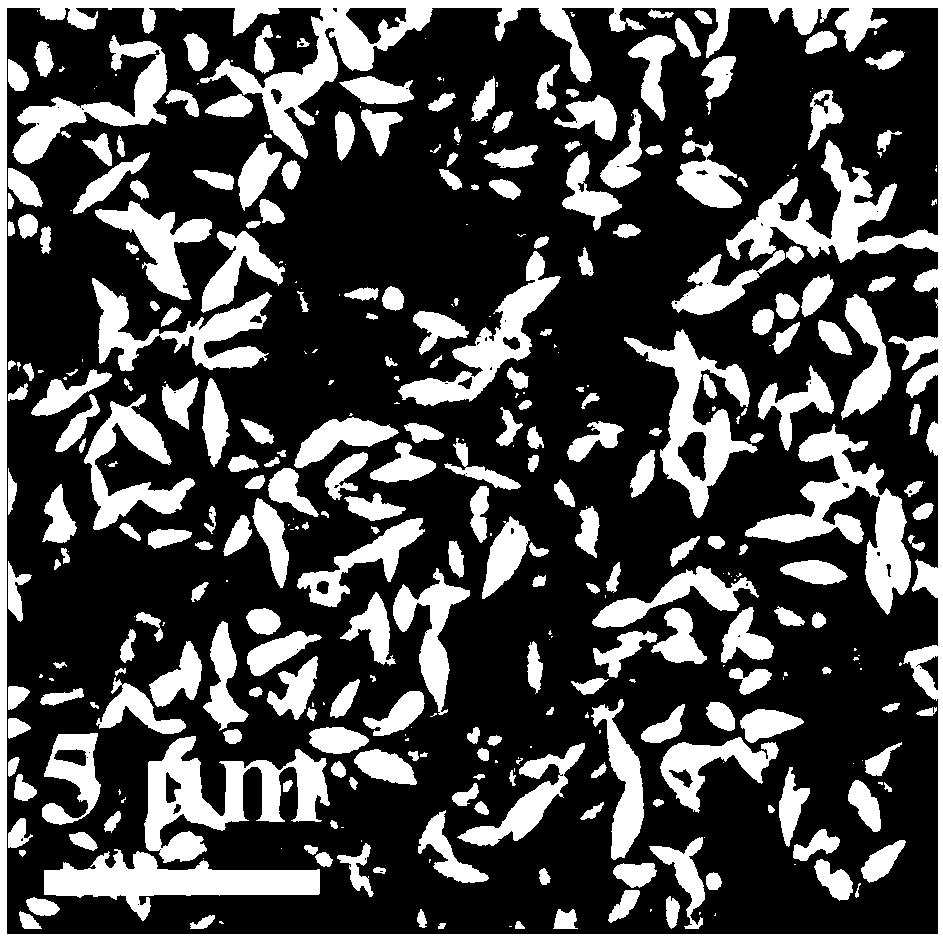

[0038] (3) Using the electrophoretic assembly method, use the Zn foil as the anode in ultrapure water, and use the rGO film in step (2) as the cathode, the distance between the two electrodes i...

Embodiment 2

[0042](1) At room temperature, weigh 500 mg of graphene oxide, place it in a 200 mL beaker, add 100 mL of distilled water to make a dispersion with a concentration of 5 mg / mL, and then process it with an ultrasonic instrument for 10.5 hours to obtain 100 mL of a graphene oxide dispersion Take 10mL of graphene oxide dispersion each time and pour it into a sand core funnel with a diameter of 4.5cm for suction filtration for 3 days to obtain a graphene oxide film.

[0043] (2) Put the graphene oxide film in the step (1) in a glass petri dish, add 20mL of 55% hydroiodic acid, seal the petri dish with the film, and place it in a dark place. After 2h, take out the film and wash it with 95% The rGO film was obtained after soaking and washing with ethanol for 3 times and drying.

[0044] (3) Using the electrophoretic assembly method, use Zn foil as the anode in ultrapure water, and use the rGO film in step (2) as the cathode, the distance between the two electrodes is 1.5cm, the appli...

Embodiment 3

[0046] (1) At room temperature, weigh 600 mg of graphene oxide, place it in a 200 mL beaker, add 100 mL of distilled water to make a dispersion with a concentration of 6 mg / mL, and then process it with an ultrasonic instrument for 11 hours to obtain 30 mL of graphene oxide slurry; The slurry was scraped to obtain a graphene oxide film.

[0047] (2) Place the graphene oxide film in step (1) in a graphitization furnace at a temperature of 400 °C. After 2 hours, take out the film and cool it to room temperature to obtain an rGO film.

[0048] (3) Using the electrophoretic assembly method, Zn foil is used as the anode in ultrapure water, and the rGO film is used as the cathode. The distance between the two electrodes is 1cm, the applied voltage is 20V / cm, the current is 1A, and the current is 0.5 hours. Take it out and dry it at room temperature. A ZnO / rGO thin film was obtained. Apply 0.1mL PFPE to 1cm 2 The ZnO / rGO film was obtained, and the fluorocarbon polymer modified chemi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com