Synthetic method of acetone-oriented multilayer CsxWO3/Ti3C2Tx composite material

A composite material and synthesis method technology, applied in the field of nano-inorganic material preparation, can solve the problems of non-selectivity, low response value, unsatisfactory response value and detection limit, etc., and achieve high detection limit, high response, excellent acetone transmission The effect of sensibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

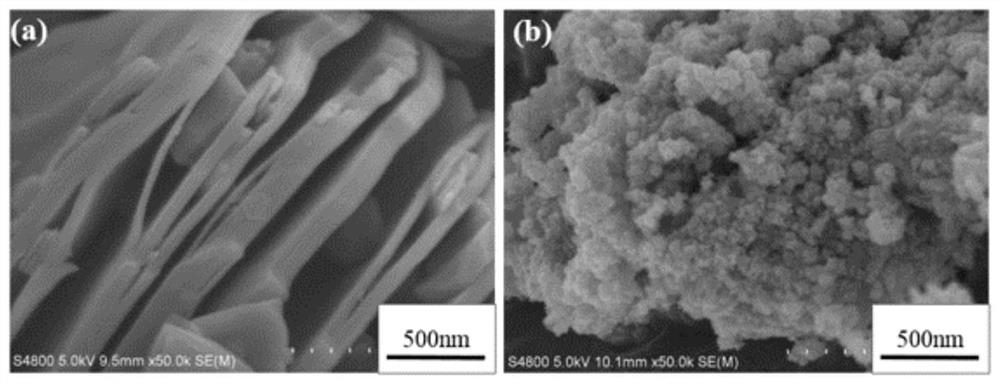

[0027] 1) Weigh 1g of Ti 3 AlC 2 , measure 20ml HF solution, Ti 3 AlC 2 Slowly add the powder into the HF solution and mix in the Teflon beaker, during which a lot of heat is released;

[0028] 2) Electromagnetic stirring to form a suspension, and after centrifugation, wash with deionized water until the solution pH=6;

[0029] 3) Use vacuum drying to obtain black Ti 3 C 2 T x sample;

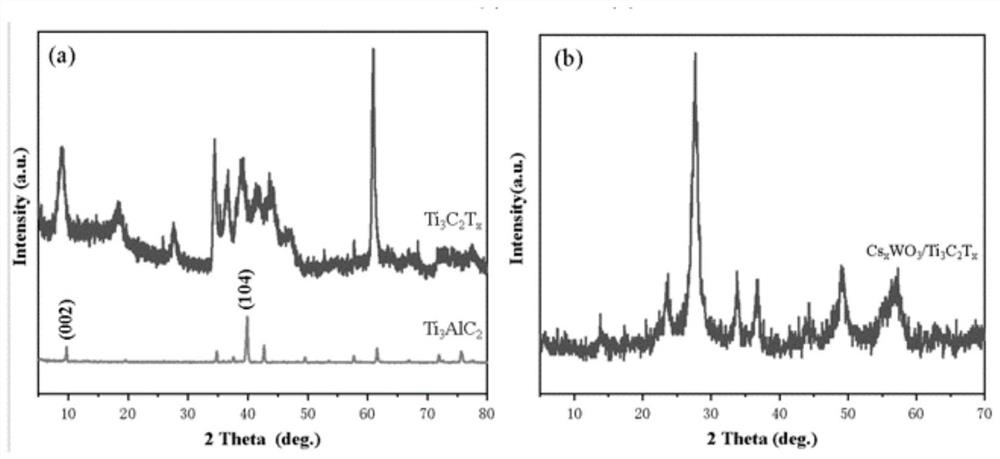

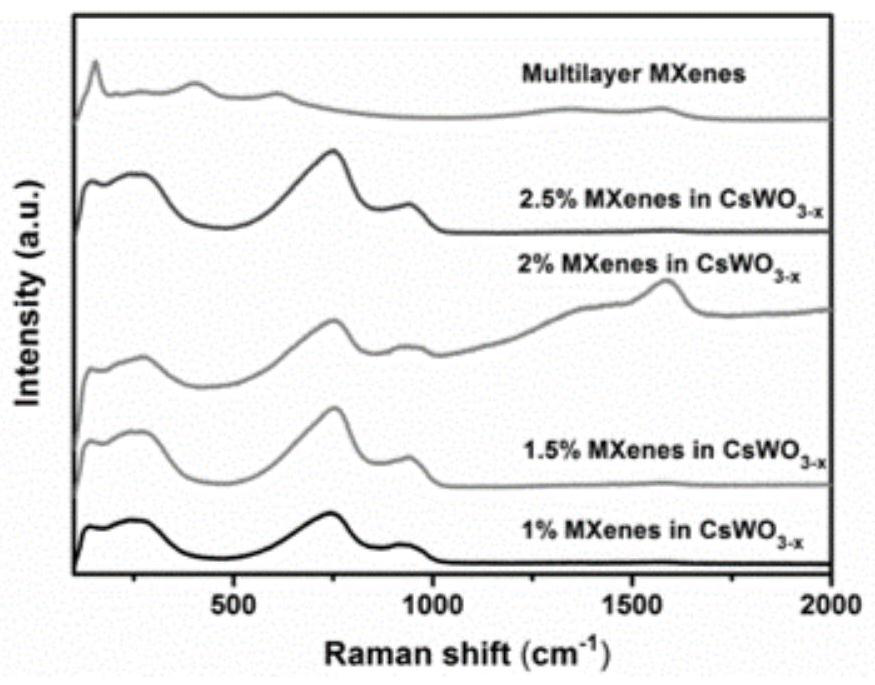

[0030] 4) Weigh 0.2g WCl 6 Dissolve in 50ml of absolute ethanol, stir vigorously until completely dissolved to obtain a light yellow solution, then add 0.1g of CsOH·H 2 O, after mixing, add a certain amount of step 3) Ti obtained 3 C 2 T x The sample and a certain amount of acetic acid form a precursor;

[0031] 5) Transfer the resulting precursor solution to a 100ml autoclave to obtain Cs x WO 3 / Ti 3 C 2 T x composite material.

[0032] Said step 2) electromagnetic stirring for 18 hours to form a suspension, and the rotational speed of the magnetic stirrer was set at 200 rpm. ...

Embodiment 2

[0037] 1) Weigh 2g of Ti 3 AlC 2 , measure 25ml HF solution, Ti 3 AlC 2 Slowly add the powder into the HF solution and mix in the Teflon beaker, during which a lot of heat is released;

[0038] 2) Electromagnetic stirring to form a suspension, and after centrifugation, wash with deionized water until the solution pH=6;

[0039] 3) Use vacuum drying to obtain black Ti 3 C 2 T x sample;

[0040] 4) Weigh 0.3g WCl 6 Dissolve in 50ml of absolute ethanol, stir vigorously until completely dissolved to obtain a light yellow solution, then add 0.3g of CsOH·H 2 O, after mixing, add a certain amount of step 3) Ti obtained 3 C 2 T x The sample and a certain amount of acetic acid form a precursor;

[0041] 5) Transfer the resulting precursor solution to a 100ml autoclave to obtain Cs x WO 3 / Ti 3 C 2 T x composite material.

[0042] Said step 2) electromagnetic stirring for 21 hours to form a suspension, and the rotational speed of the magnetic stirrer was set at 400 rpm...

Embodiment 3

[0047] 1) Weigh 3g of Ti 3 AlC 2 , measure 30ml HF solution, Ti 3 AlC 2 Slowly add the powder into the HF solution and mix in the Teflon beaker, during which a lot of heat is released;

[0048] 2) Electromagnetic stirring to form a suspension, and after centrifugation, wash with deionized water until the solution pH=6;

[0049] 3) Use vacuum drying to obtain black Ti 3 C 2 T x sample;

[0050] 4) Weigh 0.5g WCl 6 Dissolve in 50ml of absolute ethanol, stir vigorously until completely dissolved to obtain a light yellow solution, then add 0.4g of CsOH·H 2 O, after mixing, add a certain amount of step 3) Ti obtained 3 C 2 T x The sample and a certain amount of acetic acid form a precursor;

[0051] 5) Transfer the resulting precursor solution to a 100ml autoclave to obtain Cs x WO 3 / Ti 3 C 2 T x composite material.

[0052] The step 2) electromagnetically stir for 24 hours to form a suspension, and the rotational speed of the magnetic stirrer is set at 500 rpm. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com