Method for detecting NO2 by semiconductor sensor and preparation method of composite metal oxide

A composite metal and sensor technology, applied in the field of quantitative analysis of nanomaterials, can solve the problems of weak selectivity, high working temperature, poor response and recovery ability, etc., and achieve the effects of high sensitivity, good processability and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] (1) Preparation of the sensor: the composite metal oxide ZnO-NiCo 2 O 4 Disperse in a solvent so that it is evenly dispersed, use a pipette to pipette a uniformly dispersed suspension to prepare a film, and set parallel electrodes on the membrane so that the electrode spacing is 3-5mm;

[0029] (2) NO 2 Sensing testing: The prepared sensor is fixed in a closed chamber of known volume, connected to an external multimeter and DC heating power supply. Adjust the heating power supply power so that the sensor works at 50-300 ° C. Using air as the background gas, it enters the closed cavity at a certain flow rate until the resistance of the sensor is stable. After the resistance is stabilized, keep the total flow rate constant and turn on no 2 Gas valve, make NO 2 After fully mixing with the air, it enters the closed cavity and contacts the sensor, and at the same time starts the timing to record the change value of the resistance of the sensor within the specified time; Close no...

Embodiment 1

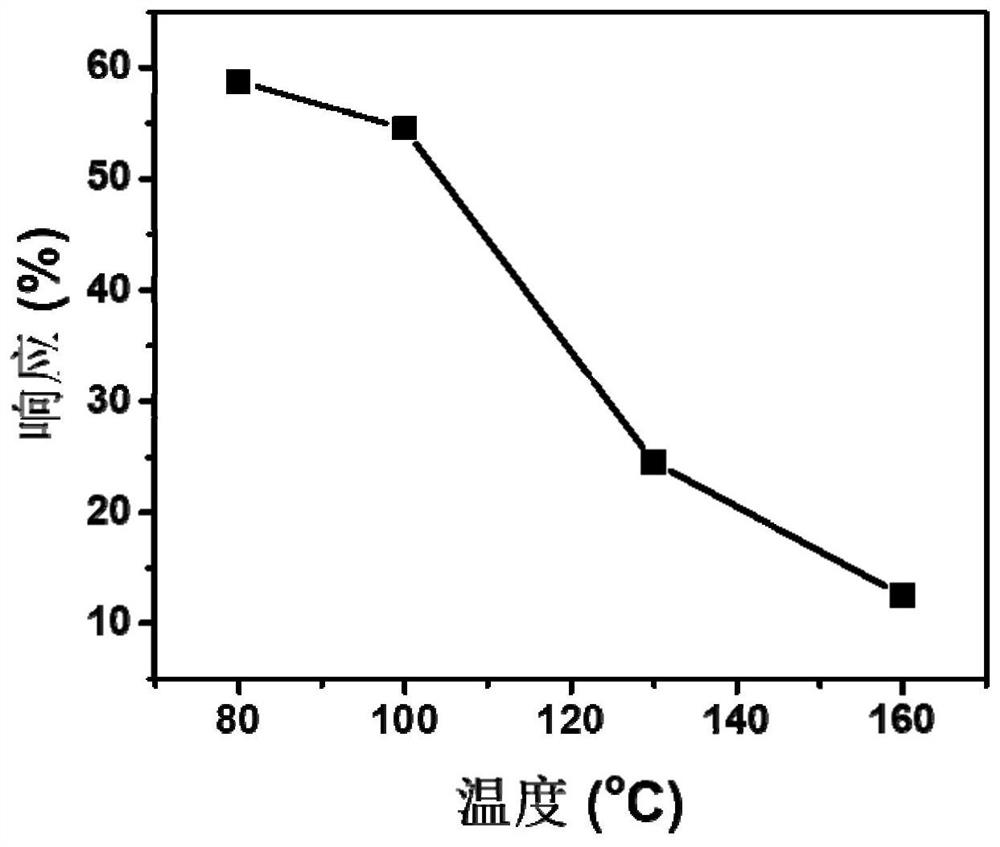

[0040] Sensor to NO 2 Test of operating temperature: Weigh 5mgZnO-NiCo 2 O 4 Composite metal oxide samples were added in a 5 mL centrifuge tube, 1.5 mL of absolute ethanol was added, and sonication was 20 min. Take 30 μL of the suspension solution with a pipette, apply evenly on the ceramic tube, and dry the oven at 40 °C for 30 min. The prepared sensor is fixed in a 500mL blue cap bottle and connected to an external multimeter and DC power supply. Adjust the power of the DC power supply so that the ceramic tube works at a certain temperature. Pass air with a flow rate of 400 mL / min into the blue cap bottle, wait for the resistance to remain stable, reduce the air flow rate to 300 mL / min, and open no 2 The gas valve regulates the flow rate of 100mL / min, the total flow rate remains unchanged, and the timing is 10min as the response time. Close no until the reaction is over 2 Gas valve, air flow rate recovery 400mL / min, so that the sensor with fresh air contact, resistance drop, tim...

Embodiment 2

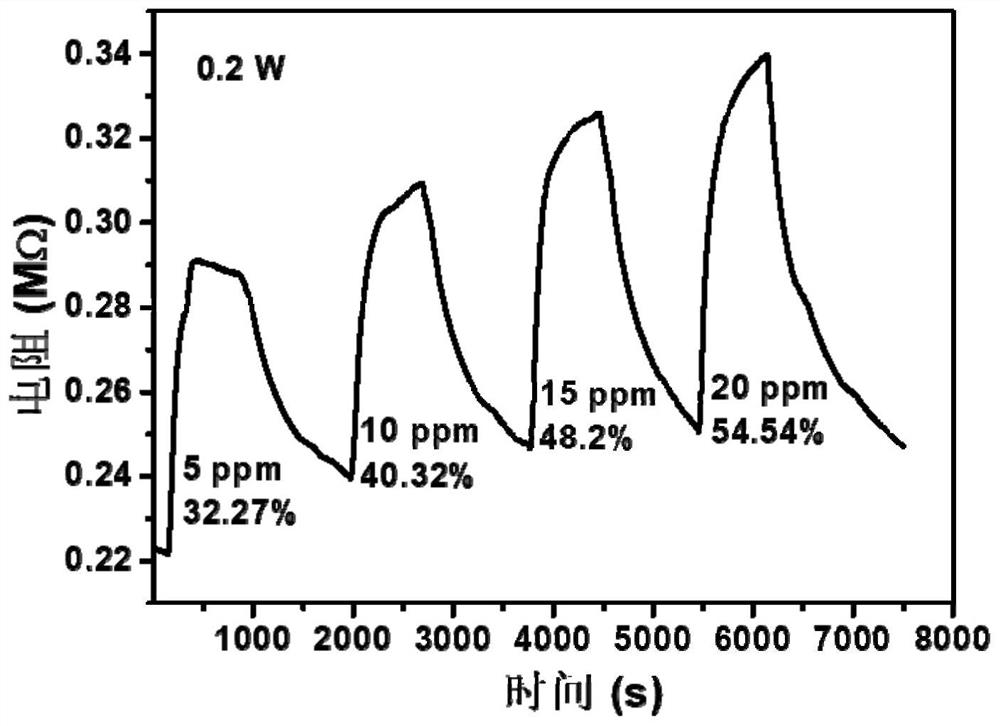

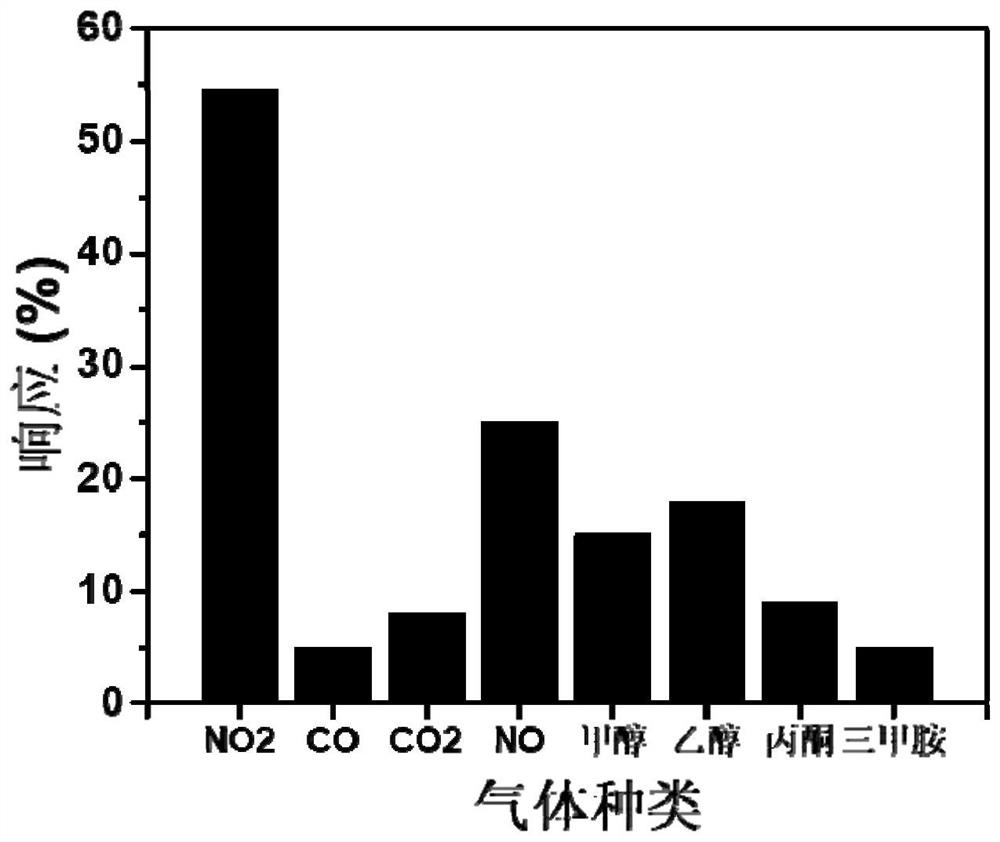

[0042] Sensor to NO 2 Concentration test: Weigh 5 mg ZnO-NiCo 2 O 4 Composite metal oxide samples were added in a 5 mL centrifuge tube, 1.5 mL of absolute ethanol was added, and sonication was 20 min. Take 30 μL of the suspension solution with a pipette, apply evenly on the ceramic tube, and dry the oven at 40 °C for 30 min. The prepared sensor is fixed in a 500mL blue cap bottle and connected to an external multimeter and DC power supply. Adjust the power of the DC power supply so that the ceramic tube works at 100 °C. Pass air with a flow rate of 400 mL / min into the blue cap bottle, wait for the resistance to remain stable, reduce the air flow rate, and open no 2The gas valve regulates the flow rate, the total flow rate remains unchanged, and the timing is 10min as the response time. Close no until the reaction is over 2 Gas valve, air flow rate recovery 400mL / min, so that the sensor and fresh air contact, resistance drop. Due to the long recovery time, the recovery time is set ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com