Underwater damage self-alarming and self-repairing material as well as preparation method and application thereof

A self-healing material and water-reactive technology, applied in the field of polymers, can solve problems such as impracticability and damage self-alarm, and achieve excellent electrical conductivity and excellent sensing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

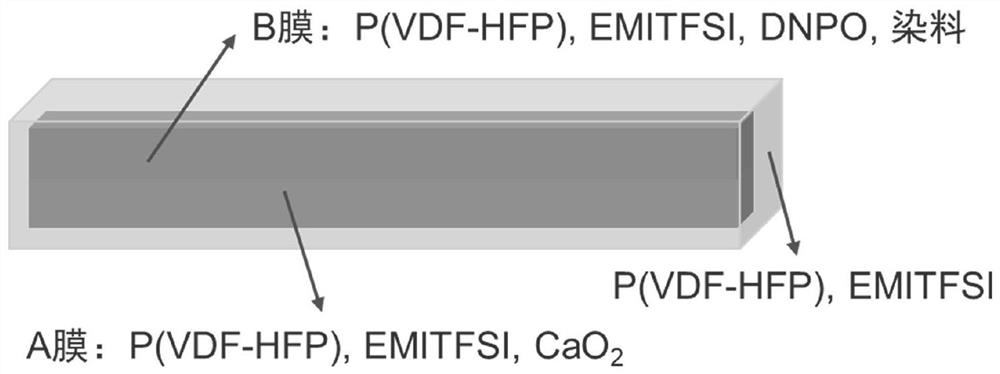

[0045] In a second aspect, the present invention provides a method for preparing the self-alarming and self-repairing material for underwater damage, comprising the following steps:

[0046] A layer is prepared by mixing a substance that can react with water to generate hydrogen peroxide, a fluorine-containing polymer, an ionic liquid and an organic solvent;

[0047] Mixing peroxyoxalate, dye, fluorine-containing polymer, ionic liquid and organic solvent uniformly, drying after rotary evaporation, and hot pressing to form a film to prepare layer B;

[0048] Superimpose layer A and layer B;

[0049] The material prepared by mixing and coupling the fluoropolymer and the ionic liquid wraps the superimposed layer of the A layer and the B layer to form a hydrophobic protective layer.

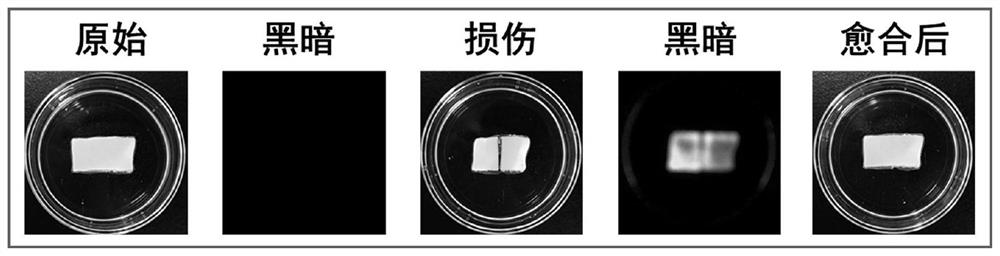

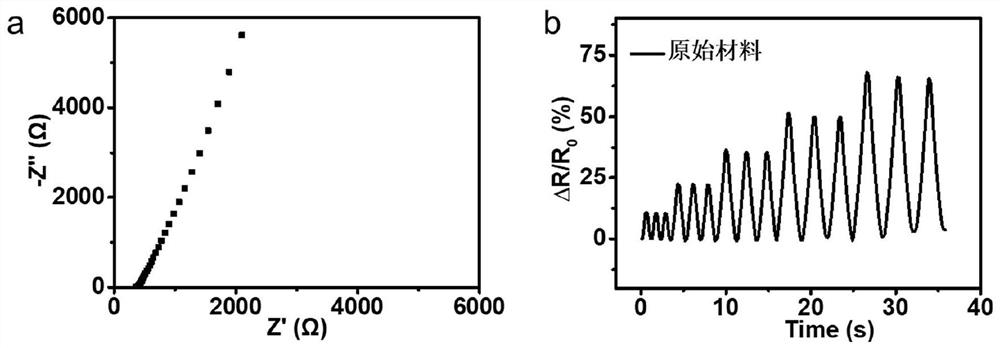

[0050] In a third aspect, the present invention provides that the underwater damage self-alarming and self-healing material has potential applications in the fields of ionic skin and strain sensor p...

Embodiment 1

[0067] Preparation method of film A: Dissolve P(VDF-HFP) (10g) and EMITFSI (8g) in acetone at room temperature to obtain a homogeneous solution and then add CaO 2 (2g). Rotary steaming, drying, and compression molding to obtain A film.

[0068] Preparation method of B film: P(VDF-HFP) (10g) and EMITFSI (8g) were dissolved in acetone at room temperature to obtain a homogeneous solution, and then DNPO (2g) and DPA (0.003g) were added. Rotary steaming, drying, and compression molding to obtain B film.

[0069] Preparation method of hydrophobic transparent film: P(VDF-HFP) (10 g) and EMITFSI (8 g) were dissolved in acetone at room temperature to obtain a homogeneous solution. Then, rotary steam, drying, and compression molding are performed to obtain a hydrophobic transparent film.

[0070] The A film and the B film are first assembled into a whole, and then tightly wrapped with a hydrophobic transparent film to obtain the final material, whose structure is as follows: figure ...

Embodiment 2

[0074] Preparation method of film A: Dissolve P(VDF-HFP) (10g) and EMITFSI (5g) in acetone at room temperature to obtain a homogeneous solution and then add CaO 2 (2g). Rotary steaming, drying, and compression molding to obtain A film.

[0075] Preparation method of film B: P(VDF-HFP) (10g) and EMITFSI (5g) were dissolved in acetone at room temperature to obtain a homogeneous solution, and then DNPO (3g) and BPEA (0.001g) were added. Rotary steaming, drying, and compression molding to obtain B film.

[0076] Preparation method of hydrophobic transparent film: P(VDF-HFP) (10 g) and EMITFSI (5 g) were dissolved in acetone at room temperature to obtain a homogeneous solution. Then, rotary steam, drying, and compression molding are performed to obtain a hydrophobic transparent film.

[0077] The A film and the B film are first assembled into a whole, and then tightly wrapped with a hydrophobic transparent film to obtain the final material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com