Photoetching method for improving adhesion degree of photoresist and substrate

An adhesion and photoresist technology, applied in the field of photolithography, can solve the problems of increasing the occupation of the hot plate, uneven primer coating, large amount of hexamethyldisilazane, etc., to improve the adhesion, meet the The effect of process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

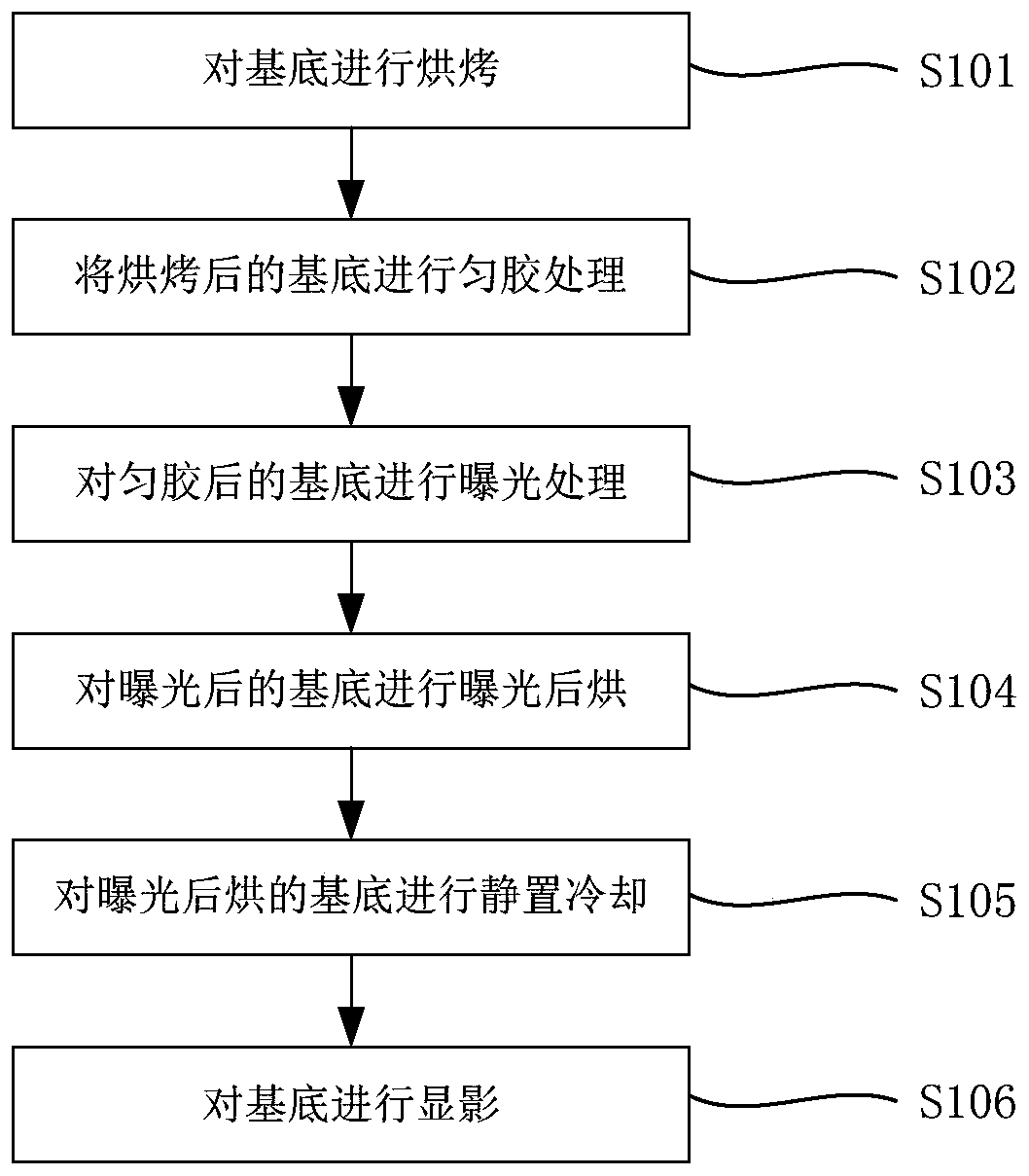

[0065] Such as figure 1 Shown, a kind of photolithography method that improves photoresist and substrate adhesion degree provided according to the present invention comprises:

[0066] Step S101, baking the substrate;

[0067] Step S102, performing glue leveling treatment on the baked substrate;

[0068] Step S103, performing exposure treatment on the substrate after uniform glue;

[0069] Step S104, performing post-exposure baking on the exposed substrate;

[0070] Step S105, standing and cooling the post-exposure baked substrate;

[0071] Step S106, developing the substrate.

[0072] The specific operation process is as follows:

[0073] First perform step S101 to bake the substrate, set the baking temperature to 160-180°C, and bake the time to 50-80s to increase the adhesion between the photoresist and the substrate; then proceed to step S102 to bake the substrate after baking Coating treatment; followed by step S103 to perform exposure treatment on the substratum aft...

Embodiment 2

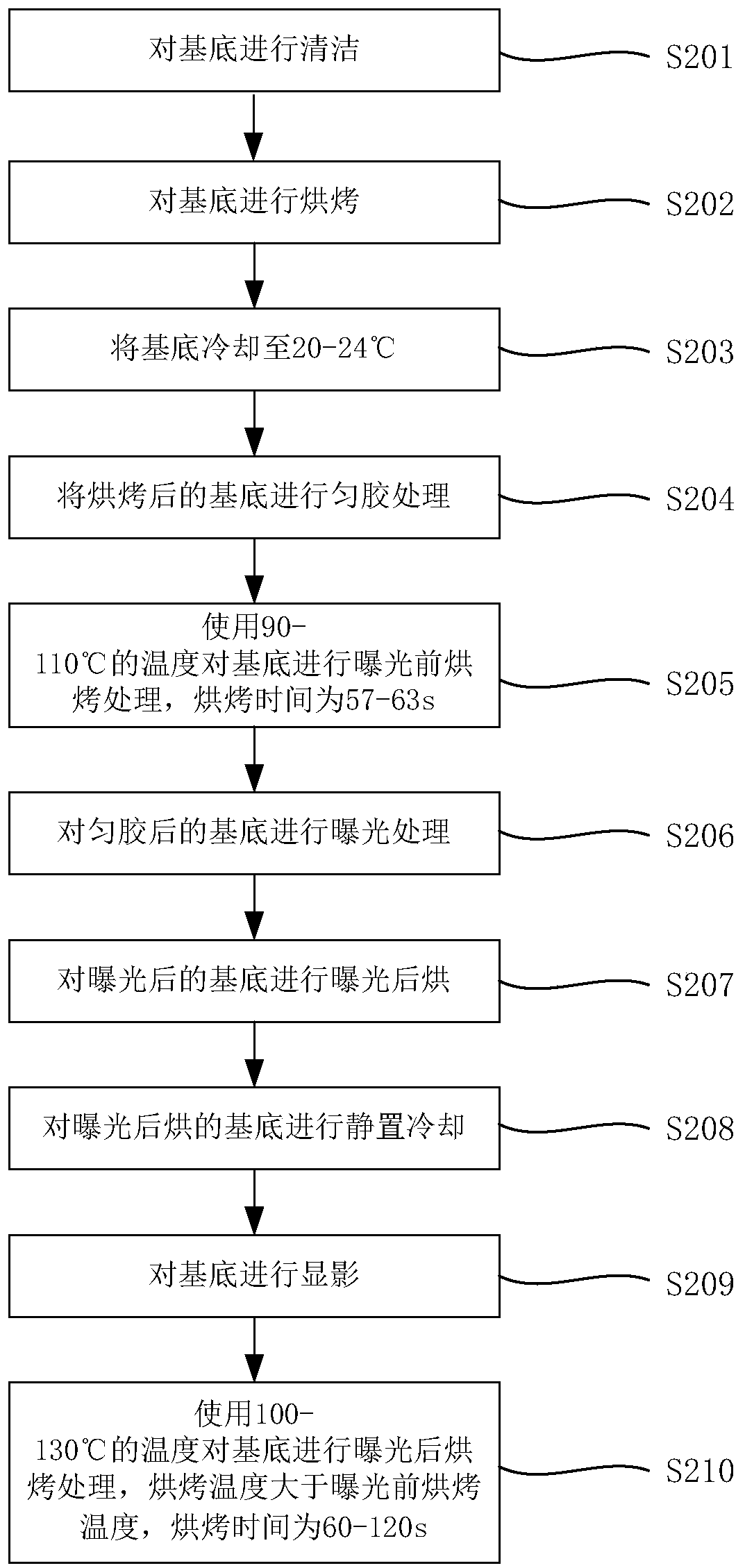

[0075] Such as figure 2 Shown, a kind of photolithography method that improves photoresist and substrate adhesion degree provided according to the present invention comprises:

[0076] Step S201, cleaning the substrate;

[0077] Step S202, baking the substrate;

[0078] Step S203, cooling the substrate to 20-24°C;

[0079] Step S204, performing glue leveling treatment on the baked substrate;

[0080] Step S205, using a temperature of 90-110°C to perform pre-exposure baking treatment on the substrate, and the baking time is 57-63s;

[0081] Step S206, performing exposure treatment on the substrate after uniform glue;

[0082] Step S207, performing post-exposure baking on the exposed substrate;

[0083] Step S208, standing and cooling the post-exposure baked substrate;

[0084] Step S209, developing the substrate;

[0085] In step S210, post-exposure baking is performed on the substrate at a temperature of 100-130° C., the baking temperature is higher than the pre-exposu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com