In-orbit ultra-long service life prediction method for fiber grating strain sensor for satellite

A strain sensor, fiber grating technology, applied in the direction of using optical devices, instruments, measurement devices, etc., can solve the problem of inability to accurately evaluate the service life of the measurement system, and achieve strong practicability, operability, and short experiment time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

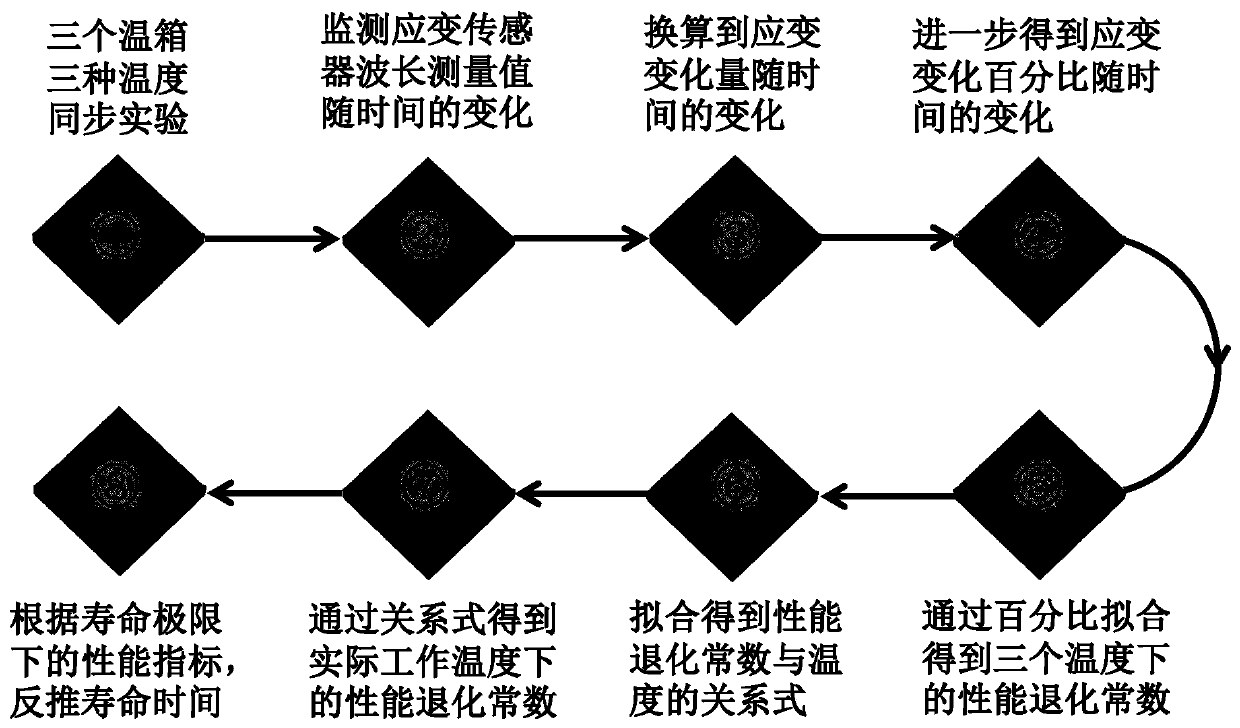

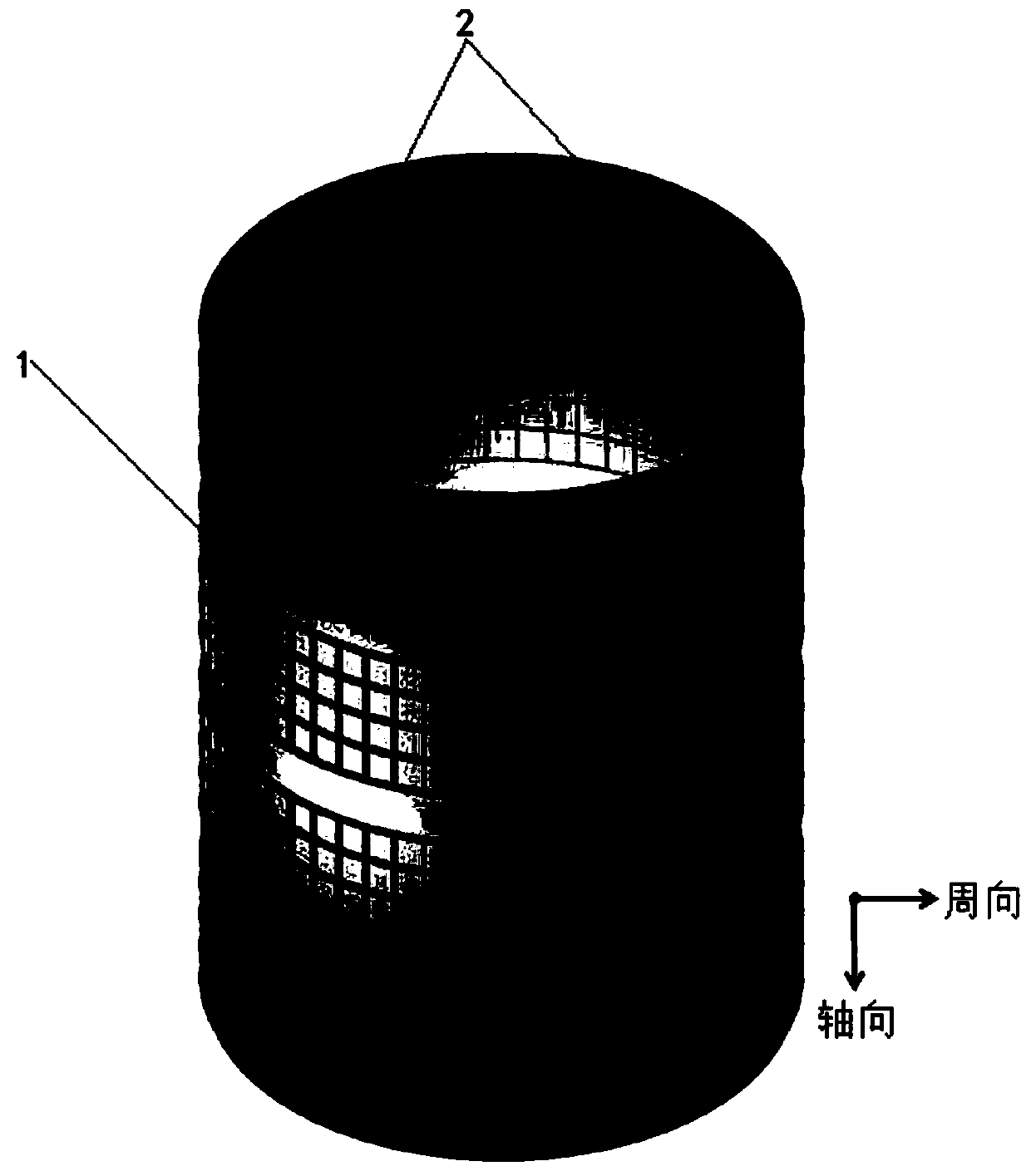

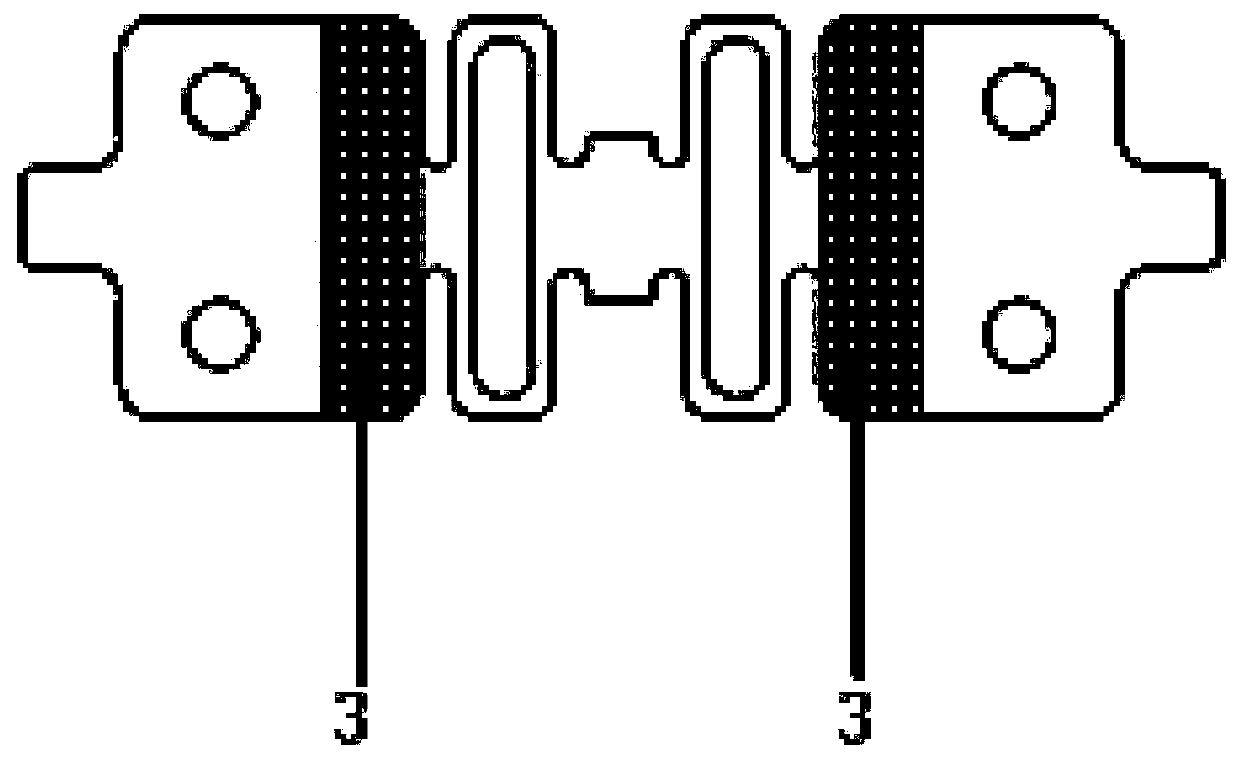

[0048] Such as figure 1 As shown, an on-orbit ultra-long life prediction method of a fiber grating strain sensor for satellites mainly includes building a strain test system for a fiber grating strain sensor. At least three sets of strain test systems are used. The temperature of the incubator is different, and the temperature of the incubator is higher than the actual working environment temperature of the optical fiber strain sensor, and the experiment is carried out synchronously; the wavelength measurement value of the strain sensor is monitored λ im Change with time, converted to strain change Δλ im Change with time, and further obtain the change of the percentage of strain change with time; through percentage fitting, the performance change constant β at three temperatures is obtained; the relationship between the performance change constant and temperature is obtained by fitting, and β and 1 / T satisfy the negative exponent relationship, the actual working temperature T...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap