Secondary battery, preparation method thereof and electric equipment

A secondary battery, solid electrolyte technology, applied in secondary batteries, electrolyte battery manufacturing, non-aqueous electrolyte batteries, etc., can solve problems such as inability to withstand high temperatures above 200°C, poor battery high temperature resistance, and poor safety performance , to achieve the effect of low cost, maintaining stability and reducing equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0084] Further, the preparation method also includes the step of sputtering a current collector on the surface of the molybdenum oxide negative electrode. An existing sputtering process can be used for the current collector, which is not particularly limited in the present invention. For example, when the current collector is titanium and platinum, an optional sputtering process is: when preparing the current collector, use metal titanium and platinum as the target material, and under the condition of flowing Ar gas, plate Fluid collection.

[0085] In a third aspect, at least one embodiment provides an electrical device, including the above-mentioned secondary battery or a secondary battery prepared by the above-mentioned preparation method. The electrical equipment includes the above-mentioned secondary battery, so it has at least the same advantages as the above-mentioned secondary battery, and has the advantages of low cost, easy storage, good cycle performance and high-t...

Embodiment 1

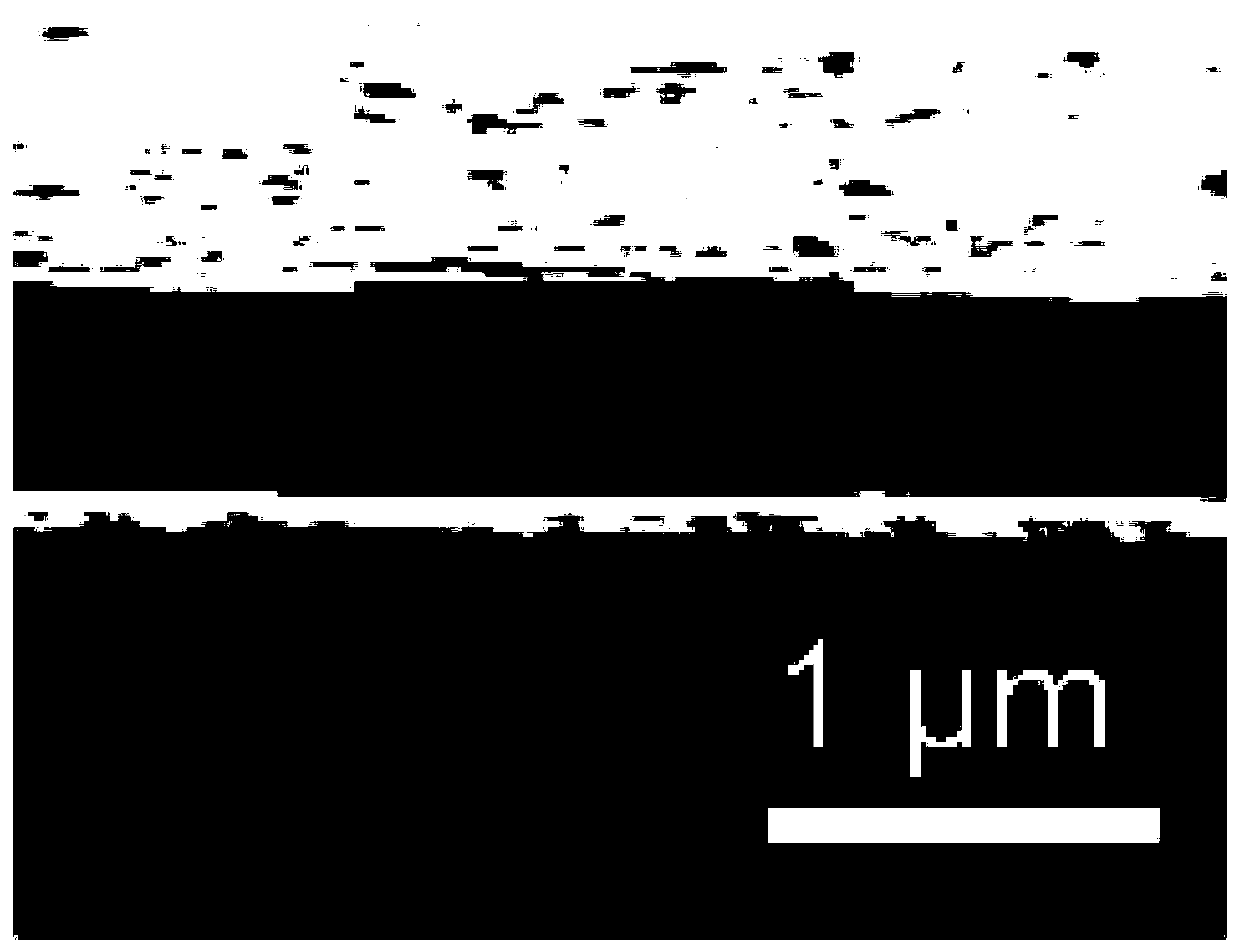

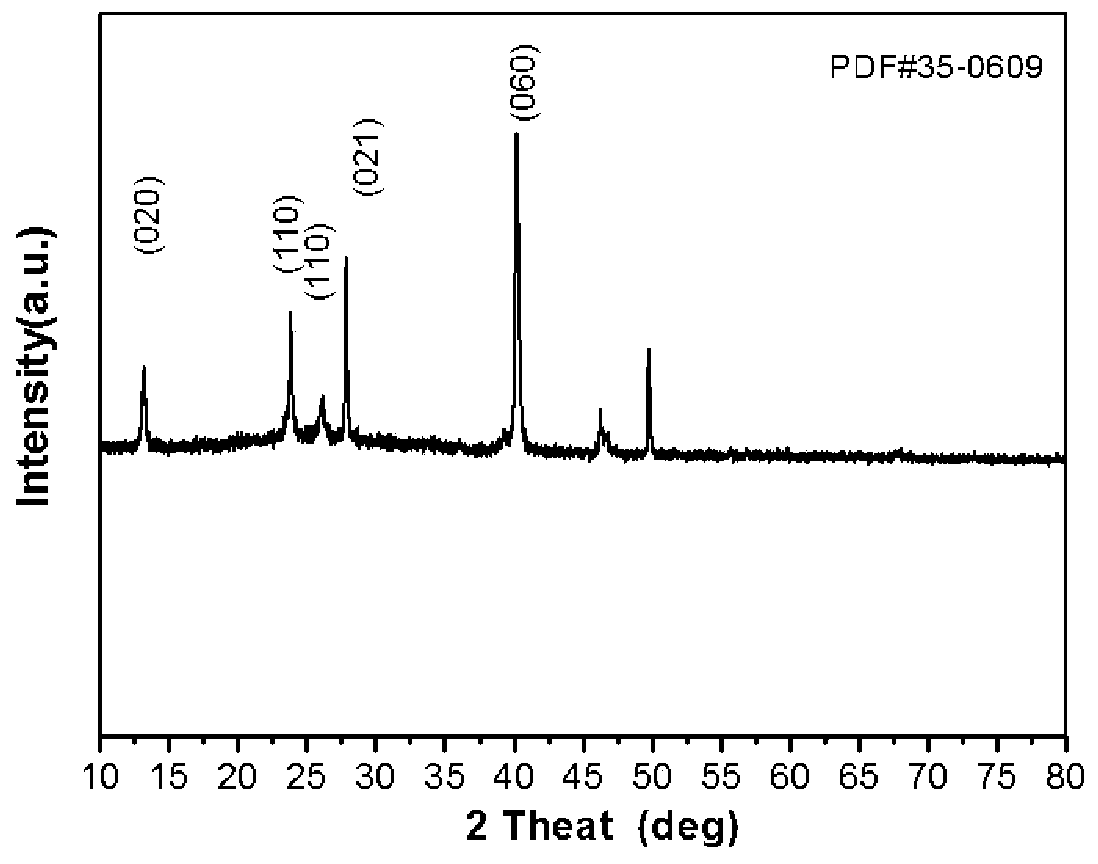

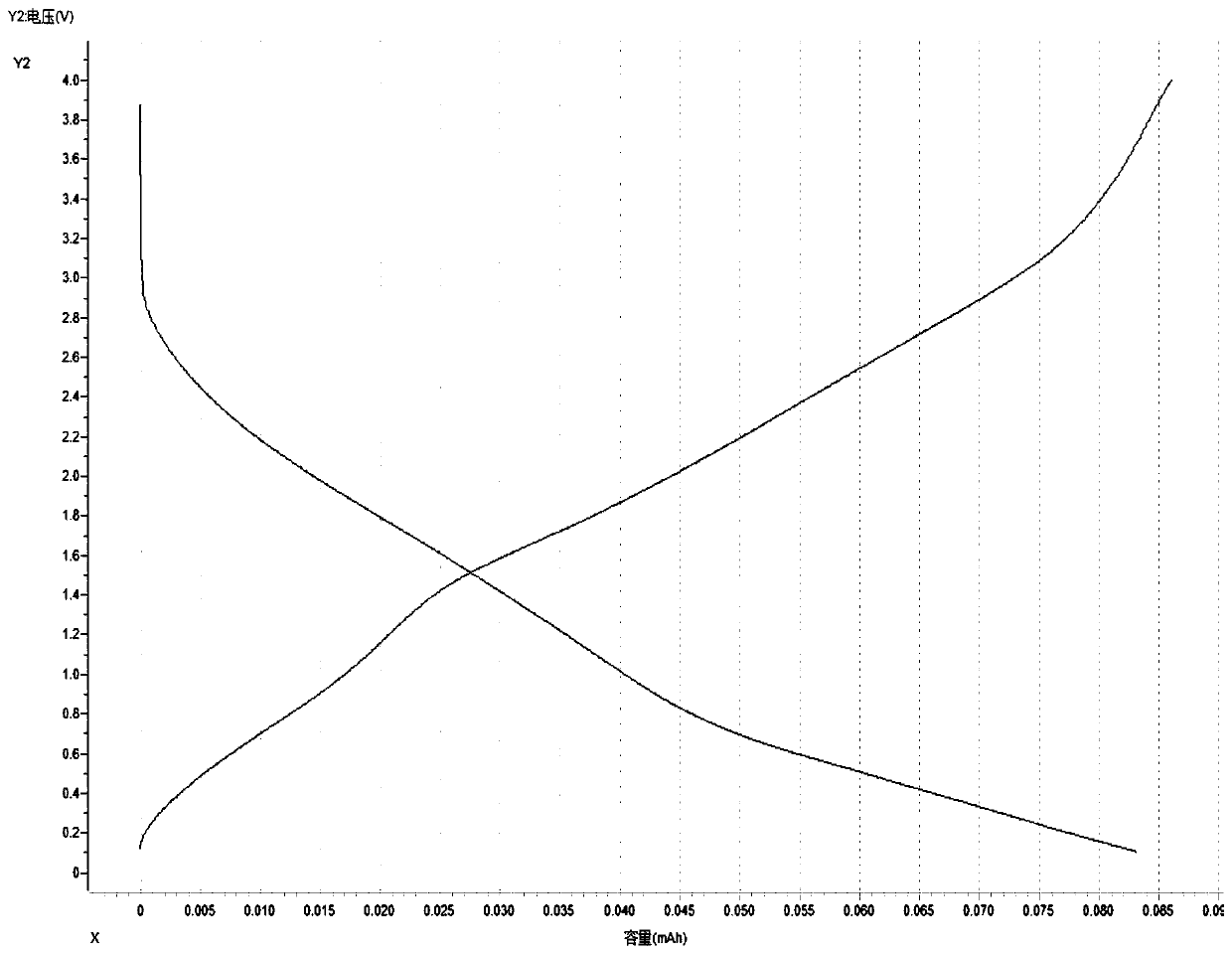

[0089] A secondary battery, comprising a molybdenum trioxide positive electrode, a lithium-containing solid electrolyte, and a molybdenum trioxide negative electrode stacked in sequence, the thickness of the molybdenum trioxide positive electrode and the molybdenum trioxide negative electrode are both 350 nm, and the thickness of the electrolyte is 4 μm. for Li 3 N.

Embodiment 2

[0091] A secondary battery, comprising a molybdenum trioxide positive electrode, a lithium-containing solid electrolyte, and a molybdenum trioxide negative electrode stacked in sequence, the thickness of the molybdenum trioxide positive electrode and the molybdenum trioxide negative electrode are both 380 nm, and the thickness of the electrolyte is 0.6 μm, The electrolyte is Li 3 P.S. 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com