A Concentration Capacitor

A capacitor and concentration difference technology, applied in the field of energy storage and conversion, can solve problems such as concentration difference, increase system cost, and easy corrosion life, and achieve the effect of alleviating the greenhouse effect, wide selection range, and easy corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

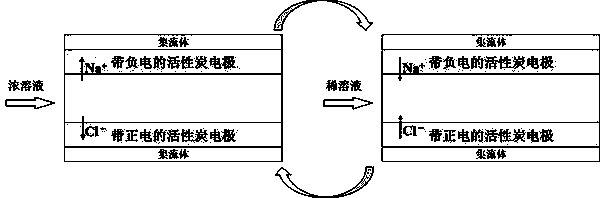

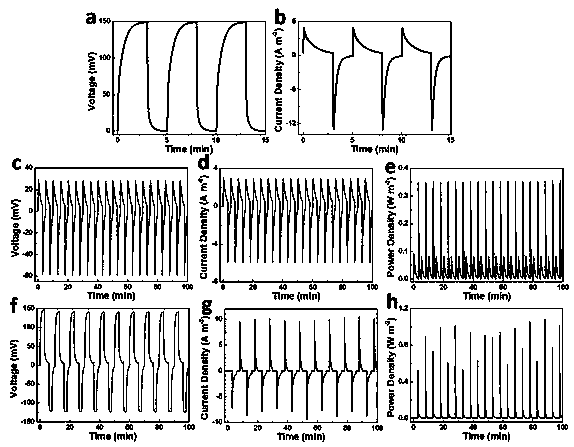

[0028] Example 1: Filmless Concentration Capacitor

[0029] The capacitor in this embodiment consists of electrodes, separators and current collectors, such as figure 1 shown.

[0030] The asymmetric electrodes are positively charged polytetra-vinylpyridine modified activated carbon electrode and negatively charged nitric acid oxidation treated activated carbon electrode. The preparation steps of the electrode are as follows:

[0031] 5 g of activated carbon was mixed with 2 ml of polytetravinylpyridine and ultrasonically dispersed in 250 ml of deionized water. The mixture is heated to 90 o C and add 36 mg of potassium persulfate, and polymerize for 24 h under the protection of nitrogen. The reaction product was vacuum filtered, washed with water and dried. The resulting solid was mixed with 50 ml N-N dimethylformamide and heated to 65 o c. Add 1 g of 1,4-dibromobutane, and cross-link for 48 h. After suction filtration and washing with ethanol, the mixture was disperse...

Embodiment 2

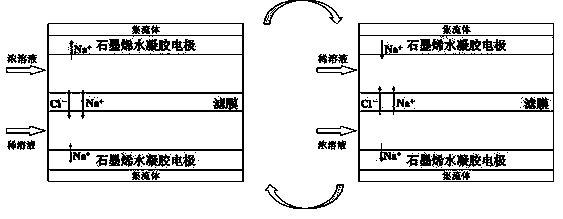

[0035] Embodiment 2: membrane type concentration difference capacitor

[0036] The capacitor in this embodiment is made up of electrode, non-selective filter membrane and current collector, as image 3 shown. The symmetrical electrodes are negatively charged graphene hydrogel electrodes. The preparation steps of the electrode are as follows:

[0037] Take 15 ml of graphite oxide dispersion with a concentration of 3 mg / ml and add it to a hydrothermal kettle with a capacity of 20 ml. Put it in the oven, 180 o C for 12 h. A columnar black graphene hydrogel can be obtained. Cut the hydrogel into tablets with a thickness of approximately 3.5-4.0 mm with a razor blade. Use a puncher with an inner diameter of 1 cm to punch out electrodes to be used on the cut hydrogel. Compress it into a titanium mesh with a tablet press. A monolithic electrode without binder can be obtained.

[0038] The filter membrane is a commercially available common mixed cellulose filter membrane.

...

Embodiment 3

[0040] Embodiment 3: Anion exchange membrane type concentration difference capacitor

[0041] The capacitor in this embodiment consists of electrodes, an anion exchange membrane that only allows anions to pass through, and a current collector, such as Figure 5 shown. The symmetrical electrodes are negatively charged graphene hydrogel electrodes.

[0042] The preparation of graphene hydrogel electrodes is as described in Example 2.

[0043] The anion exchange membrane is the AHA membrane of Japan ASTOM Company.

[0044] Sodium chloride solutions with concentrations of 20 mM and 500 mM flowed simultaneously through two channels separated by a filter membrane between the electrodes. When the upper channel passes through the concentrated solution and the lower channel passes through the dilute solution, the sodium ions in the concentrated solution are adsorbed on the negatively charged graphene hydrogel electrode, and the anions will pass through the filter membrane and enter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com