Preparation method of composite beta-PbO2/manganese ore powder electrode

A composite electrode and manganese ore powder technology, applied in the electrode field, achieves the effect of compact electrode structure, good electrode stability, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

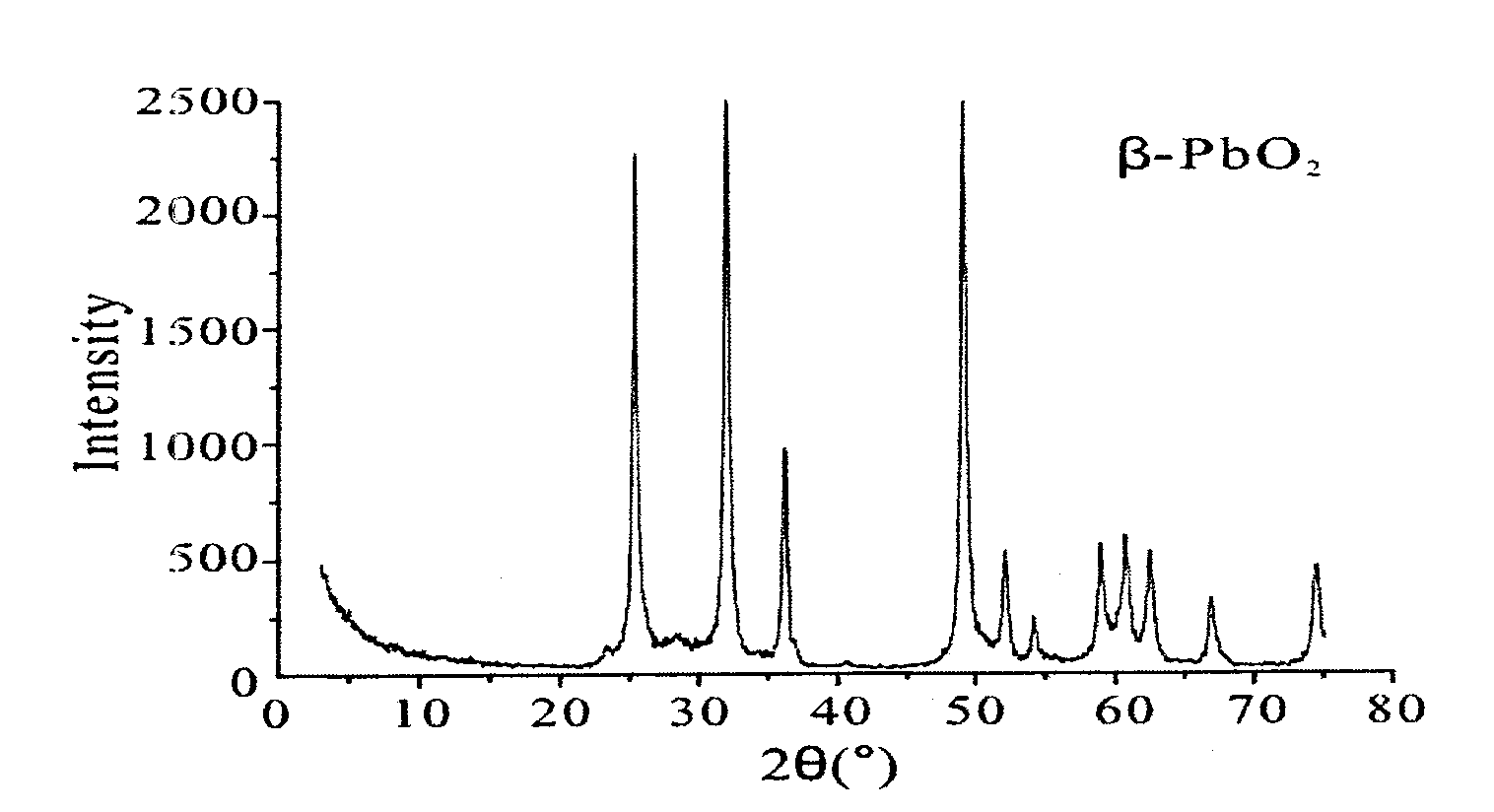

[0027] 1. β-PbO 2 preparation of

[0028] 10g Pb(Ac) 2 Dissolve in 20mL water, adjust the pH value between 9.0 and 10.0 with NaOH, add 80mL Na 2 ClO, stirred evenly, and reacted at about 90°C for about 6 hours, and the obtained precipitate was filtered, washed and dried to obtain a dark brown powder. XRD test shows that the powder is β-PbO 2 , and has excellent electrical conductivity.

[0029] 2. Preparation of lead-manganese composite electrode

[0030] Get the pyrolusite powder and pulverize it through a 200-mesh sieve. spare.

[0031] (1) Take β-PbO 2 35 parts, 65 parts of pyrolusite powder, 2 to 5 parts of polytetrafluoroethylene binder (FDPF), mixed and ground evenly, molded into a sheet with a FW4 tablet press machine, and the electrode size is 13mm.

[0032] (2)β-PbO 2 99.9 parts, 0.1 part of pyrolusite powder, 2 to 5 parts of FDPF, the operation is the same as (1).

[0033] (3)β-PbO 2 40 parts, 60 parts of pyrolusite powder, 2 to 5 parts of FDPF, the ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com