A comprehensive measurement system for the emission of printing and dyeing materials in dyeing houses

A comprehensive measurement and material technology, applied in grain processing, carpet cleaning, cleaning machinery, etc., can solve the problems of increasing equipment use costs, shortening equipment use costs, and picking up pipeline blockages, so as to reduce equipment use costs and reduce manual labor cost, and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

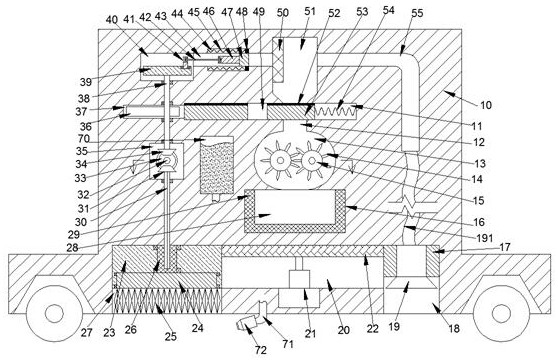

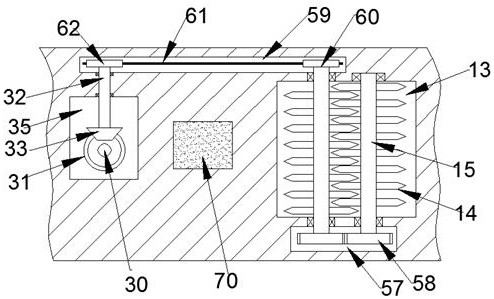

[0026] Such as Figure 1-2 As shown, a comprehensive measurement system for the discharge of printing and dyeing substances in a dyeing workshop of the present invention includes a cleaning vehicle 10, and the right side of the bottom end surface of the cleaning vehicle 10 is provided with a right storage tank 18 with an opening downward, and the right storage tank 18 is slidingly installed There is a sliding seat 17, the sliding seat 17 is provided with a vacuum cleaner 19, the top of the vacuum cleaner 19 is connected with a flexible pipe 191, and the top end surface of the cleaning vehicle 10 is provided with a cavity 51, and the left side of the cavity 51 The inner wall is fixed with a filter screen 50, and the inner wall on the right side of the cavity 51 is provided with a suction pipe 55 communicating with the flexible pipe 191; wherein, the cleaning vehicle 10 below the cavity 51 is provided with a crushing Cavity 13, a crushing mechanism is provided in the crushing ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com