Kovar alloy and tungsten copper alloy connecting method

A tungsten-copper alloy and alloy technology, which is applied in the connection field of Kovar alloy and tungsten-copper alloy, can solve the problems such as failure to meet the application requirements of the connection joint between Kovar alloy and tungsten-copper alloy, reduction of joint performance, residual thermal stress, etc. Achieve the effect of small residual thermal stress, low production cost and short time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

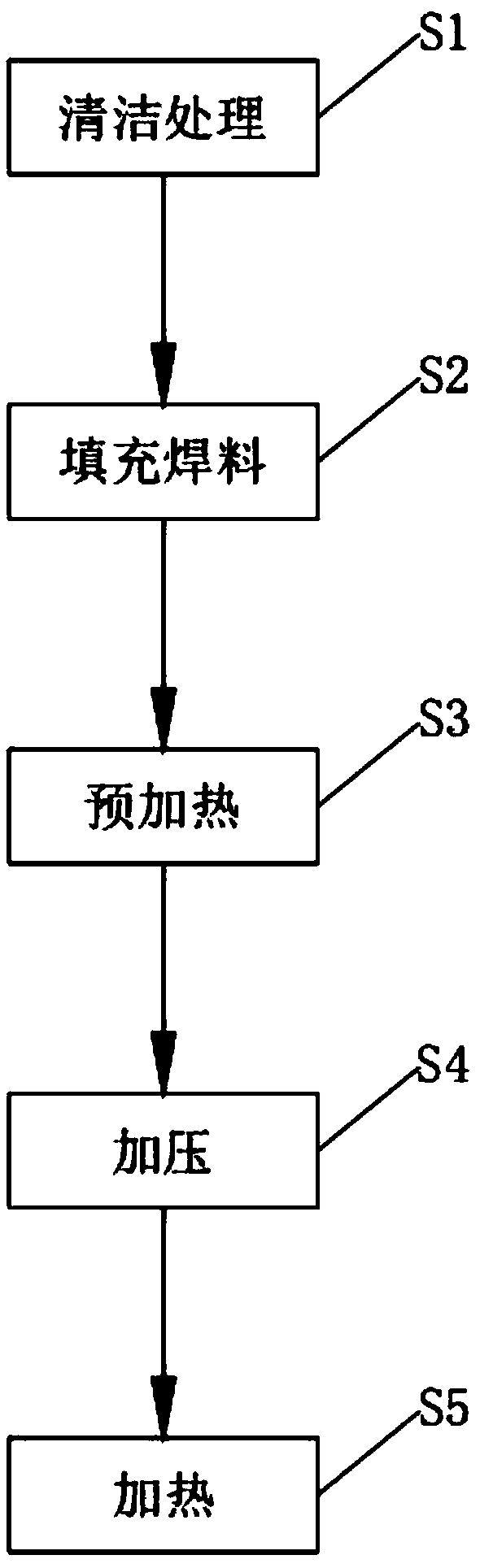

[0036] Put the Kovar alloy and tungsten-copper alloy to be joined into acetone and ultrasonically clean them for 17 minutes.

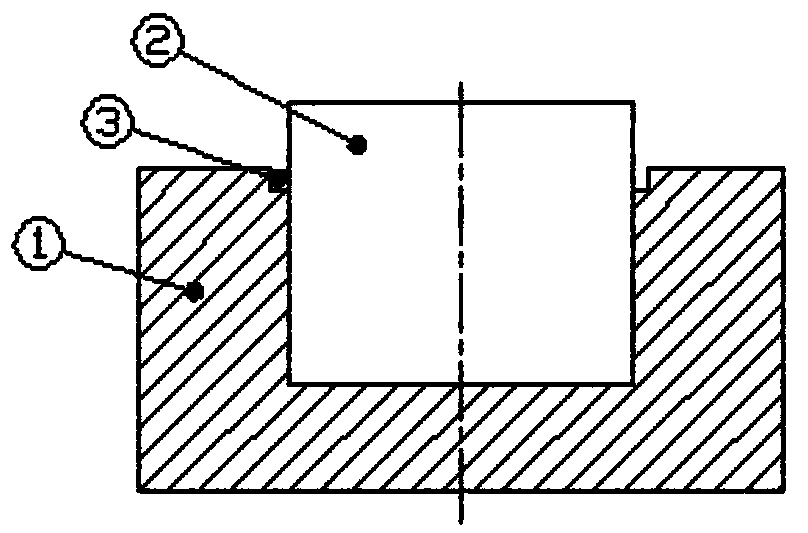

[0037] Sprinkle the solder evenly around the edges of the Kovar alloy to be connected, with a height of 1.5mm and a width of 1mm. The tolerance between the Kovar alloy and the tungsten-copper alloy is 0.0005mm.

[0038] Place the Kovar alloy, tungsten-copper alloy and solder in a 50Pa heating furnace, and raise the temperature from room temperature to 875°C at a rate of 10°C / min, and then keep it warm for 30min.

[0039] Fill the heating furnace with high-purity argon until the pressure in the heating furnace rises to 3.5 MPa.

[0040] The Kovar alloy, tungsten-copper alloy and solder are heated up to 1040°C to realize the connection between the Kovar alloy and the tungsten-copper alloy.

[0041] The joint obtained by adopting the method of this embodiment is complete and dense, without defects such as cracks, and realizes the reliable connection betw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com