Preparation method of a bionic coupled water-collecting aluminum alloy anti-icing surface

An aluminum alloy surface and aluminum alloy technology, applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problem of hydrophobic surface losing anti-icing ability, and achieve easy large-area preparation, excellent surface stability and durability, and low cost cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

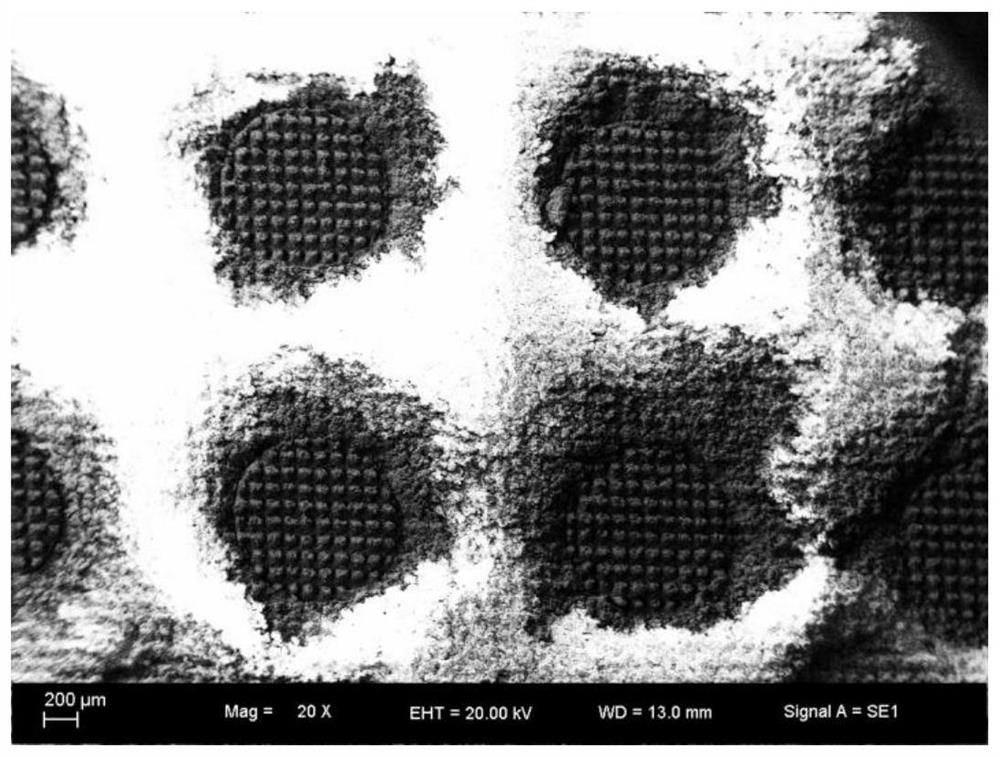

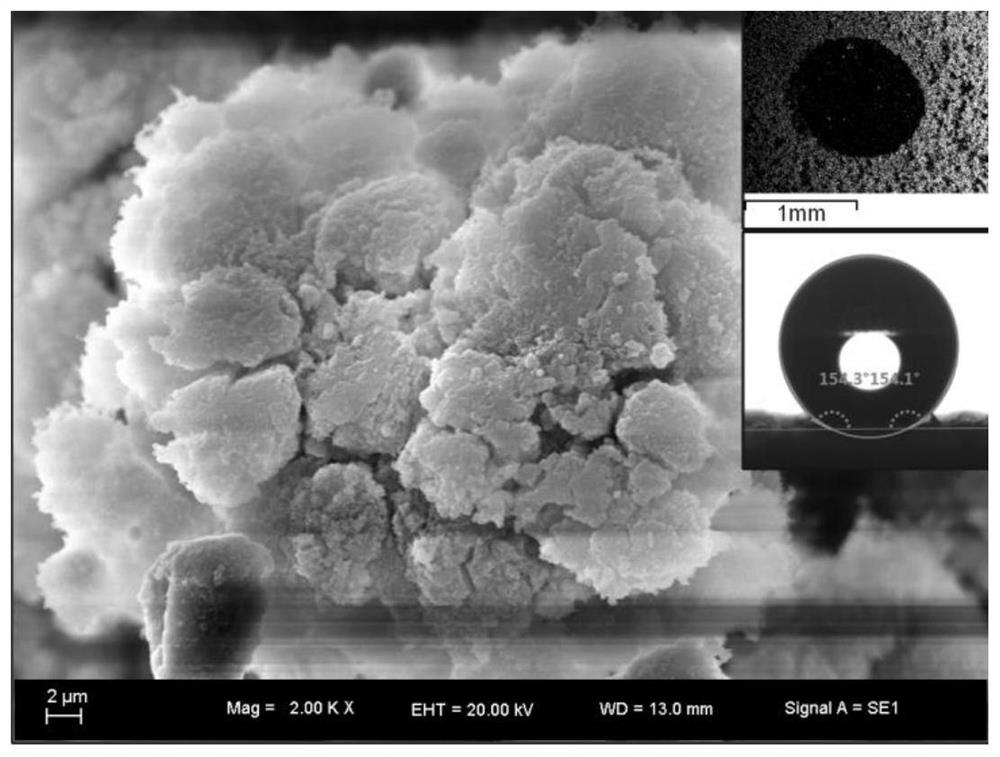

[0026] The invention relates to a preparation method of a bionic coupling water-collecting aluminum alloy anti-icing surface. The microstructure of the back of a desert beetle with water-collecting function is used as a design prototype, and a laser engraving technology and a brushing process are used to prepare an imitation desert beetle back cover. The micro-nano-level water-collecting structure surface with water function further verifies the application of its anti-icing function.

[0027] The method first adopts the laser ablation processing technology, the purpose is to design and change the surface morphology of the aluminum alloy, prepare a regular micro-column array structure, and prepare a uniform coating on the surface of the microstructure by brushing; Laser ablation prepares the surface with water collection function, the specific steps are as follows:

[0028] A. Pretreatment of the aluminum alloy surface: the aluminum alloy surface is polished with 800#, 1500#, ...

Embodiment 1

[0041] A method for preparing a bionic coupled water-collecting aluminum alloy anti-icing surface, comprising the following steps:

[0042] A. Pretreatment of the aluminum alloy surface: the aluminum alloy surface is polished with 800#, 1500#, 2000# sandpaper in turn to remove the surface oxide layer, and the polished aluminum alloy surface is placed in acetone, absolute ethanol and distilled water for ultrasonic cleaning , to remove dirt on the surface;

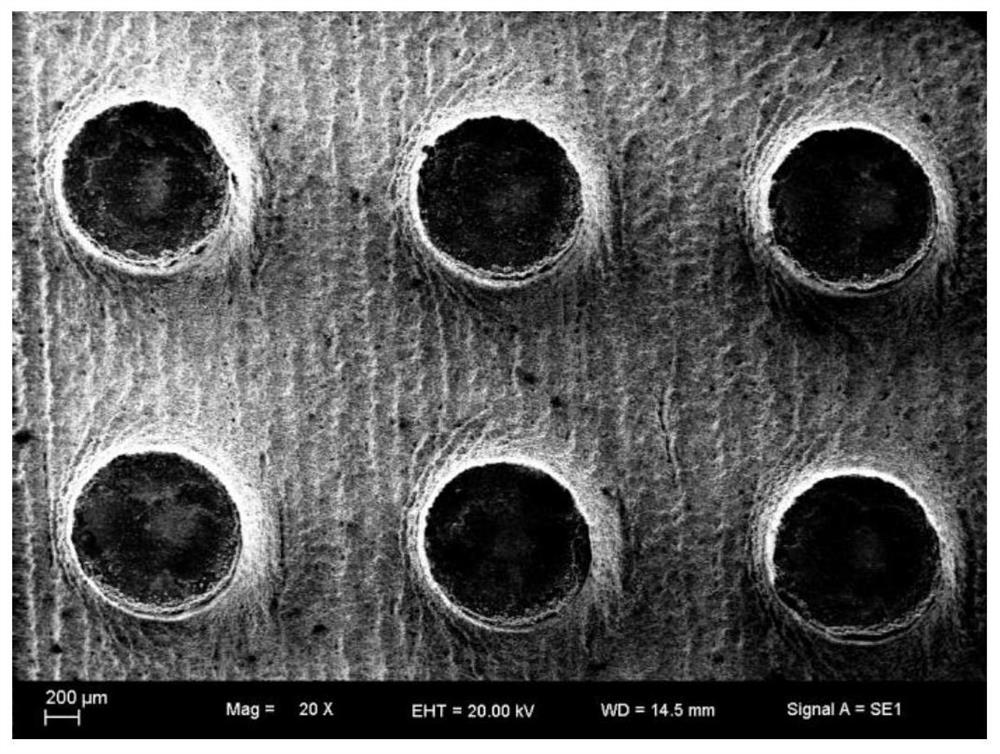

[0043] B. Preparation of surface micro-nano hierarchical structure: use a laser engraving machine to perform laser ablation on the pretreated aluminum alloy surface to prepare an aluminum alloy surface with a microstructure. The ratio of the diameter to the distance between two adjacent microcolumns is 1:2, and the height of the microcolumns is 0.5mm;

[0044] Subsequently, the surface of the aluminum alloy with microstructure was placed in acetone, absolute ethanol and distilled water for ultrasonic cleaning to remove the ...

Embodiment 2

[0051] A method for preparing a bionic coupled water-collecting aluminum alloy anti-icing surface, comprising the following steps:

[0052] A. Pretreatment of the aluminum alloy surface: the aluminum alloy surface is polished with 800#, 1500#, 2000# sandpaper in turn to remove the surface oxide layer, and the polished aluminum alloy surface is placed in acetone, absolute ethanol and distilled water for ultrasonic cleaning , to remove dirt on the surface;

[0053] B. Preparation of surface micro-nano hierarchical structure: use a laser engraving machine to perform laser ablation on the pretreated aluminum alloy surface to prepare an aluminum alloy surface with a microstructure. The ratio of the column diameter to the distance between two adjacent micro-pillars is 1:1, and the height of the micro-pillars is 0.5mm;

[0054] Subsequently, the surface of the aluminum alloy with microstructure was placed in acetone, absolute ethanol and distilled water for ultrasonic cleaning to re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com