Surface dense enhancement concrete heat preservation and moisturizing composite curing method

A technology of concrete and concrete surfaces, applied in the processing of building materials, construction, building construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

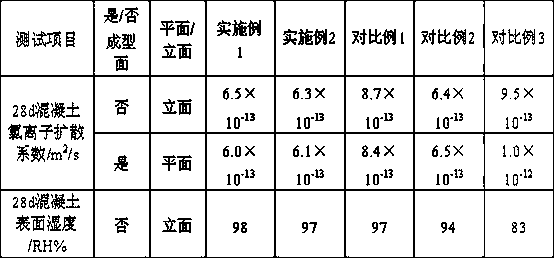

Embodiment 1

[0020] The concrete thermal insulation and moisturizing maintenance method capable of surface compaction and enhancement combines nano-silica sol with thermal insulation and moisture-retention curing film for concrete maintenance. In the composite maintenance method, the particle size range, spraying amount and spraying timing of nano-silica sol are limited. , the heat preservation and moisturizing maintenance film has specific structural characteristics of water storage and release. The particle size of the nano-silica sol particles is 20 nm, and the spraying amount is 10 g / m 2 , Spray within 30 minutes after the cast-in-place concrete forming surface is plastered. The water storage layer of the thermal insulation and moisturizing maintenance film is composited by water-absorbing fiber with a saturated water absorption rate of 20 times and a modified resin with a saturated water absorption rate of 100 times.

Embodiment 2

[0022] The concrete thermal insulation and moisturizing maintenance method capable of surface compaction and enhancement combines nano-silica sol with thermal insulation and moisture-retention curing film for concrete maintenance. In the composite maintenance method, the particle size range, spraying amount and spraying timing of nano-silica sol are limited. , the heat preservation and moisturizing maintenance film has specific structural characteristics of water storage and release. The particle size of the nano-silica sol particles is 8 nm, and the spraying amount is 4 g / m 2 , Spray within 30 minutes after the cast-in-place concrete non-forming surface is demolished. The water storage layer of the thermal insulation and moisturizing maintenance film is composited by water-absorbing fibers with a saturated water absorption rate of 30 times and a modified resin with a saturated water absorption rate of 50 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com