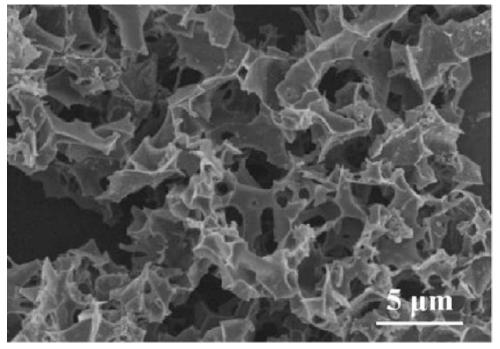

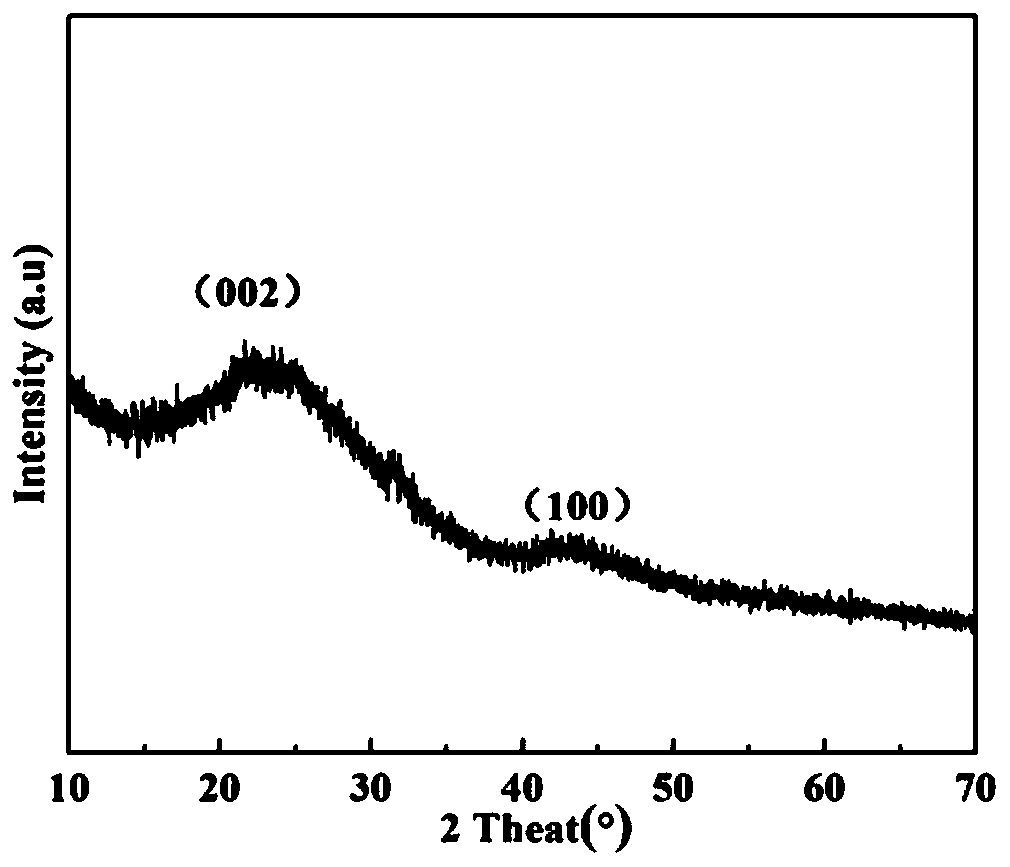

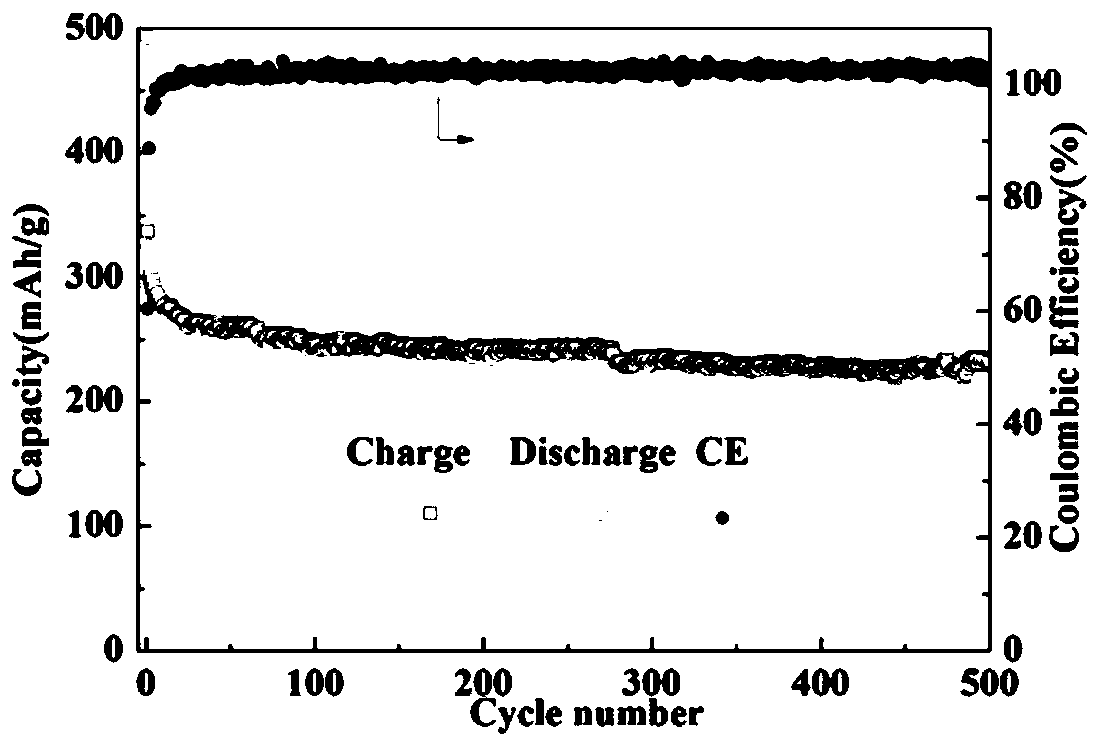

Preparation process of phosphorus-doped biomass three-dimensional porous carbon nano electrode material for long-service-life sodium ion battery

A sodium-ion battery, three-dimensional porous technology, applied in battery electrodes, active material electrodes, nanotechnology for materials and surface science, etc., can solve the problems of high energy consumption and complicated process, and achieve improved cycle life and preparation The effect of simple process and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1. The nut shells of biomass waste were ultrasonically cleaned with deionized water and ethanol at a frequency of 30KHz for 1 hour, dried with an infrared lamp for 3 hours, and then crushed into powder with a grinder, and passed through a 300-mesh sieve to obtain A;

[0041] 2. Weigh 1g of A, add 40ml of phosphoric acid solution with a concentration of 1mol / L to the above powder A, and use an ultrasonic machine to sonicate at a frequency of 20KHz for 10min to obtain mixture B.

[0042] 3. Transfer the mixture B to the hydrothermal induction kettle, and add carbon cloth with length, width and height of 3cm, 3cm, and 0.1cm as the induction source. Move the hydrothermal induction kettle into the hydrothermal induction heating equipment, raise the temperature from room temperature to 150°C with an induction frequency of 200KHz, and keep it warm for 20 minutes, then cool to room temperature, take out the carbon cloth, scrape off the obtained product and wash it with deionized...

Embodiment 2

[0046] 1. The egg shells of biomass waste were ultrasonically cleaned with deionized water and ethanol at a frequency of 30KHz for 1 hour, dried with an infrared lamp for 4 hours, and then crushed into powder with a pulverizer, and passed through a 400-mesh sieve to obtain A;

[0047]2. Weigh 2g of A, add 50ml of phosphoric acid solution with a concentration of 2mol / L to the above powder A, and use an ultrasonic machine to sonicate at a frequency of 30KHz for 20min to obtain mixture B.

[0048] 3. Transfer the mixture B to the hydrothermal induction kettle, and add carbon cloth with length, width and height of 3cm, 3cm, and 0.1cm as the induction source. Move the hydrothermal induction kettle into the hydrothermal induction heating equipment, raise the temperature from room temperature to 160°C with an induction frequency of 300KHz, and keep it warm for 30 minutes, then cool to room temperature, take out the carbon cloth, scrape off the obtained product and wash it with deioniz...

Embodiment 3

[0052] 1. Clean the biomass waste coffee husk with deionized water and ethanol sequentially at a frequency of 30KHz for 1 hour, dry it with an infrared lamp for 5 hours, then crush it into powder with a pulverizer, and pass it through a 500-mesh sieve to obtain A;

[0053] 2. Weigh 3g of A, add 60ml of phosphoric acid solution with a concentration of 2mol / L to the above powder A, and use an ultrasonic machine to sonicate at a frequency of 30KHz for 20min to obtain mixture B.

[0054] 3. Transfer the mixture B to the hydrothermal induction kettle, and add carbon cloth with length, width and height of 3cm, 3cm, and 0.1cm as the induction source. Move the hydrothermal induction kettle into the hydrothermal induction heating equipment, raise the temperature from room temperature to 170°C with an induction frequency of 400KHz, and keep it warm for 40 minutes, then cool to room temperature, take out the carbon cloth, scrape off the obtained product and wash it with deionized water an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com