Up-drawn copper and aluminum material continuous casting machine unit based on internet of things

A technology of the Internet of Things and continuous casting machines, applied in the field of machinery and automation, can solve problems such as high energy consumption and low production efficiency, and achieve the effects of compact equipment structure, reduced labor costs, and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

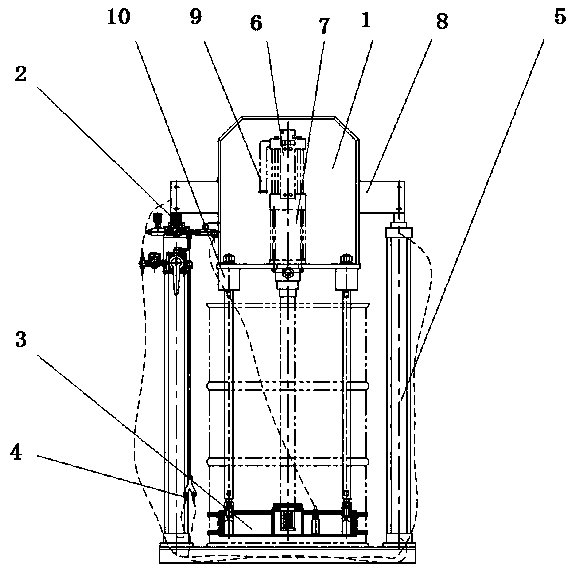

[0022] An Internet of Things upward-drawing method copper and aluminum continuous casting unit comprises a power frequency induction furnace 1, a continuous casting machine 2, a guide wheel frame 3, a tension device 4, a double-head bending rod machine 5, a water cooling system 6, an electrical system 7, The feeding system 8, the temperature measurement system 9 and the data acquisition module 10, the power frequency induction furnace 1 runs through the bottom surface of the power frequency induction furnace 1 and is fixedly connected with an electrical system 7, and the top of the electrical system 7 is directly connected to the water cooling system 6. Fixed connection, A temperature measurement system 9 is provided on one side of the water cooling system 6, a feeding system 8 is provided on the left and right sides of the power frequency induction furnace 1, and a double-head bending rod machine 5 is provided below the feeding system 8 on one side of the power frequency induct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com