Rapid cutter servo device with dynamic force balance function

A servo device and dynamic force technology, applied in the direction of manufacturing tools, metal processing machinery parts, maintenance and safety accessories, etc., can solve problems such as dynamic forces that are difficult to ignore, and achieve the effects of saving design space, improving efficiency, and compact volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings.

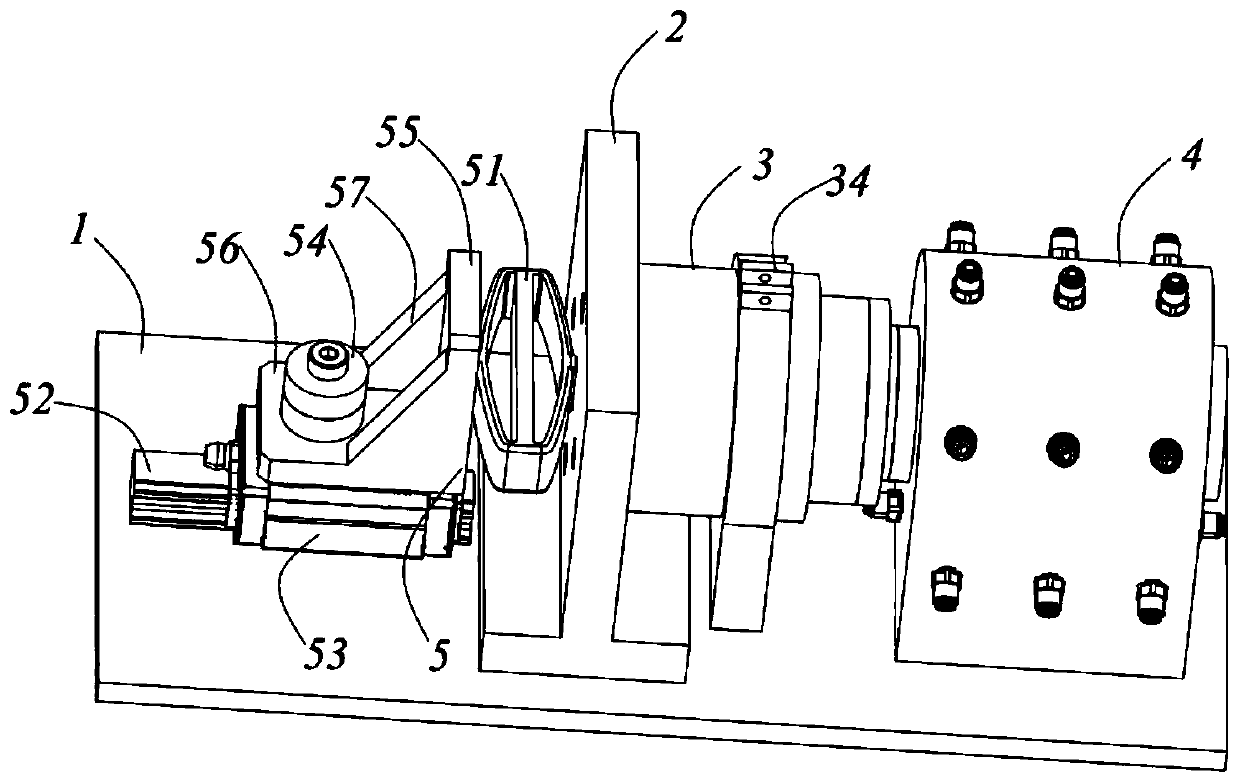

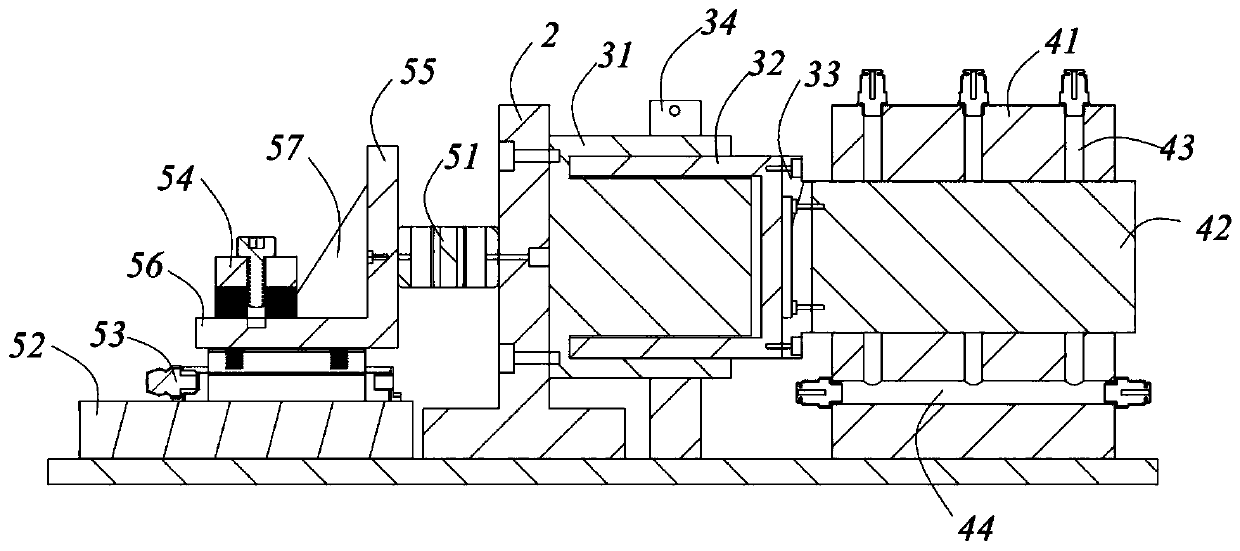

[0021] Such as figure 1 and figure 2 A fast tool servo device with dynamic force balance function is shown, including a base 1 arranged on the machine tool, a motor assembly 3 arranged on the base 1, a first guide rail assembly 4 arranged on the motor assembly 3, and a first guide rail assembly 4 arranged on the first The tool on the guide rail assembly 4 is fixed with a connector 2 on the base 1, the motor assembly 3 is fixed on one side of the connector 2, and the other side of the connector 2 is provided with a balance The motor assembly 3 moves a balance assembly 5 that generates dynamic force. The movement of the motor assembly 3 causes the tool on the first guide rail assembly 4 to move to realize the machining of the workpiece by the tool. Due to the dynamic force generated by the movement of the motor assembly 3, a balance assembly 5 is provided on the oth...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap