Electrochemical method for removing trivalent Sb

An electrochemical and electrode technology, which is applied in the field of removing trivalent Sb, can solve the problems of low efficiency and long time consumption, and achieve the effect of flexible operation, efficient removal, and not easy to secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

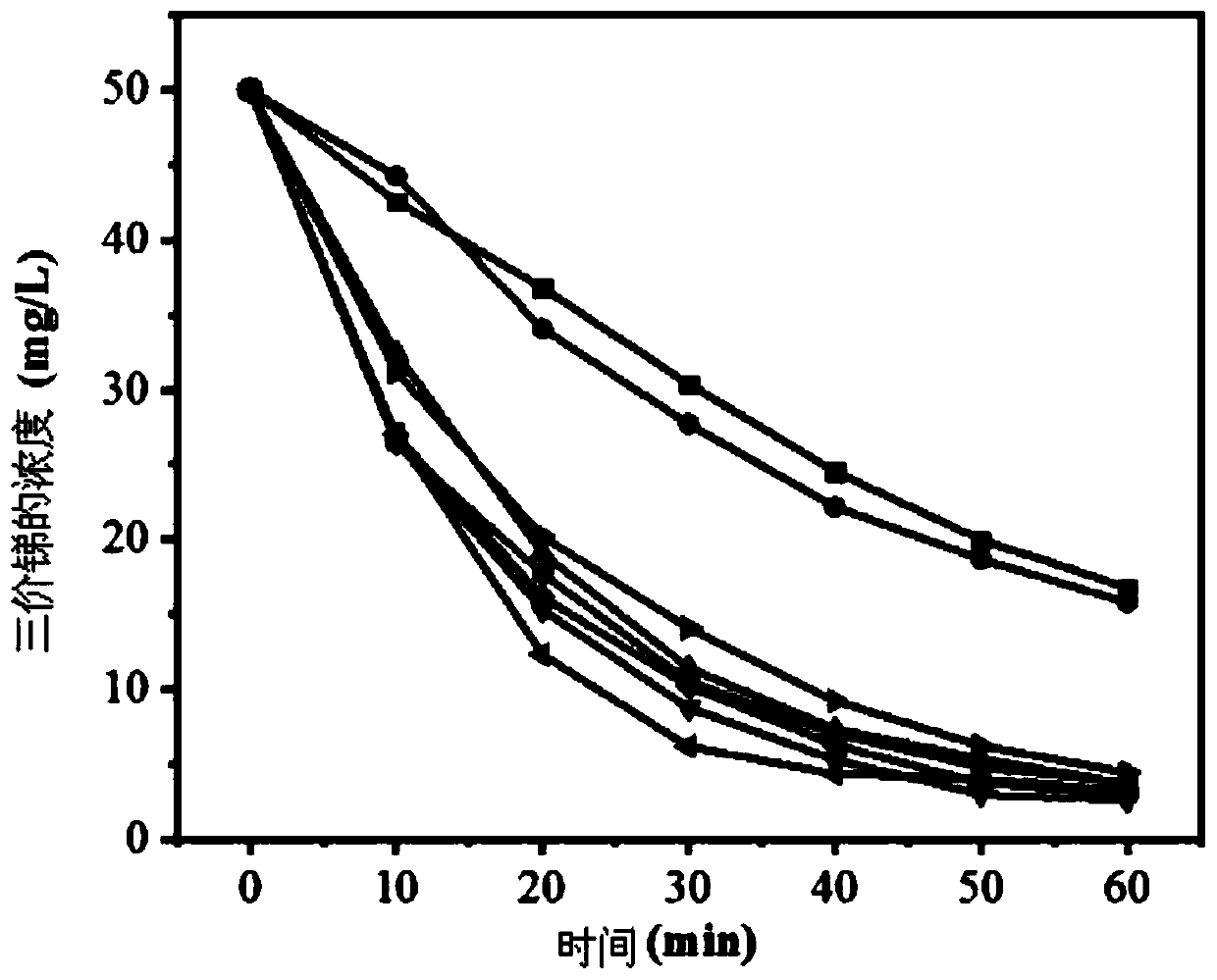

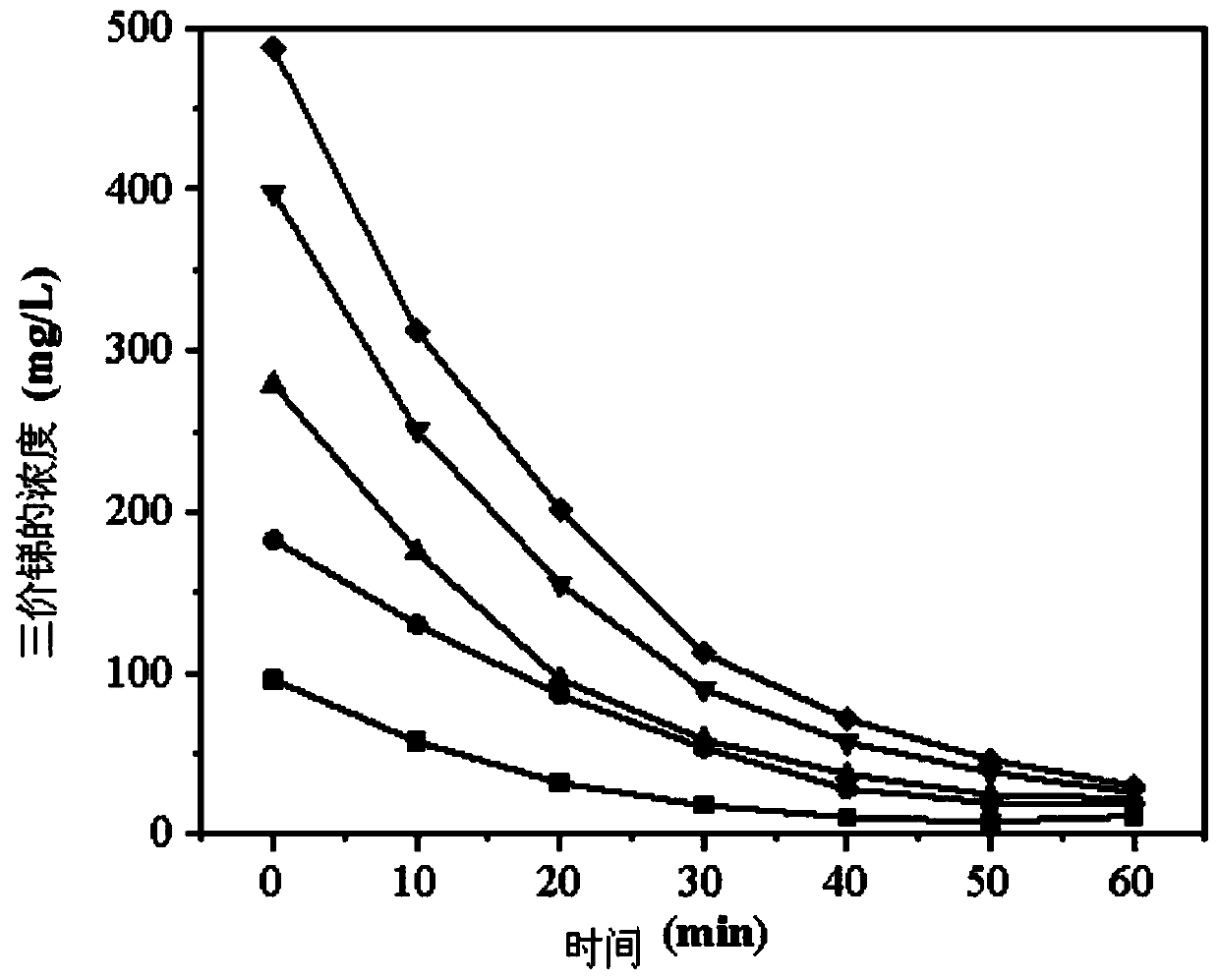

[0021] Specific embodiment one: this embodiment is an electrochemical method for removing trivalent Sb, specifically carried out according to the following steps:

[0022] 1. In the electrochemical workstation, set the Pt electrode as the counter electrode, the carbon cloth as the working electrode, and the Ag / AgCl electrode as the reference electrode;

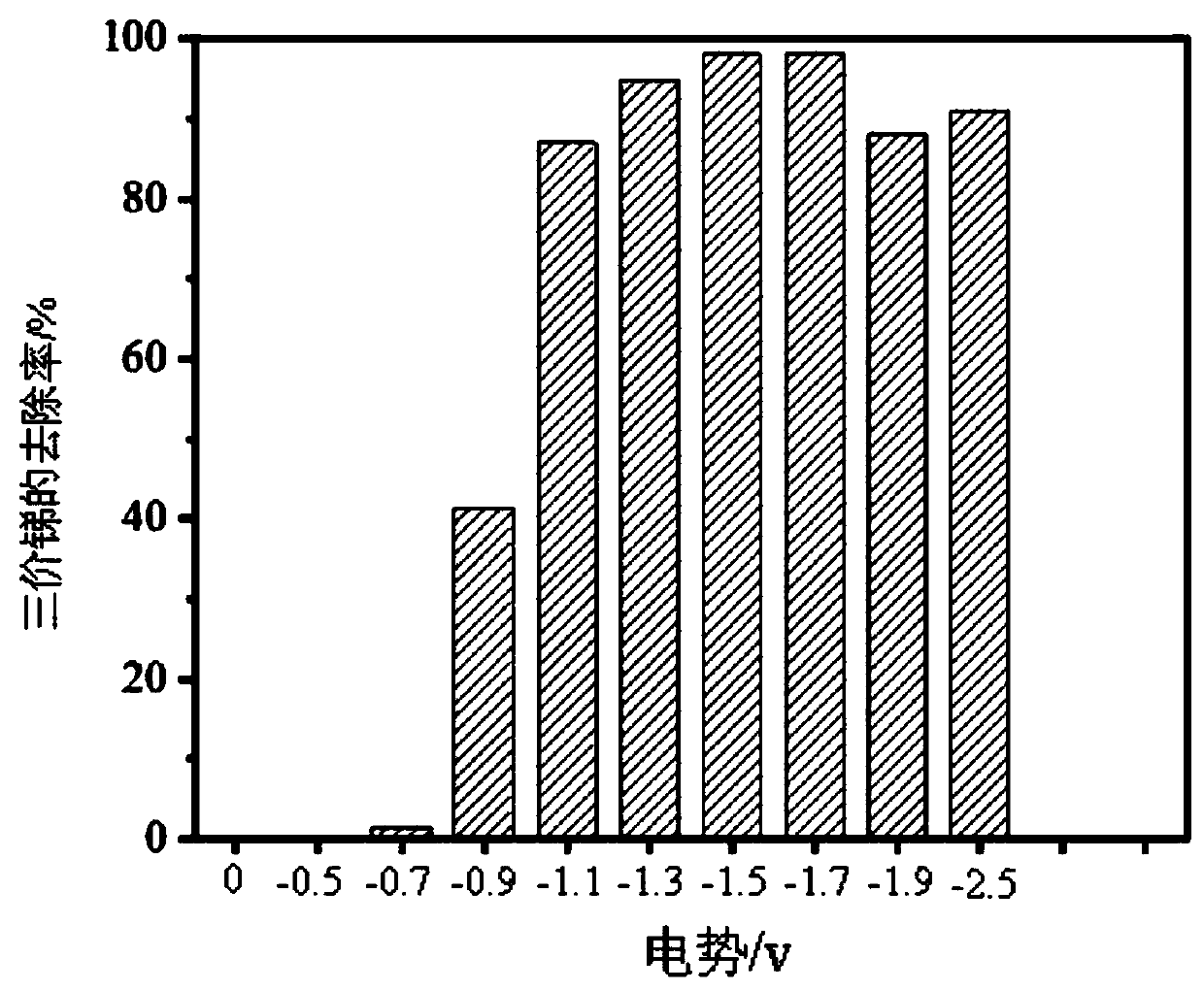

[0023] 2. Pass the water to be treated containing trivalent Sb into the electrolytic cell of the electrochemical workstation, adjust the pH of the solution in the electrolytic cell to 3~10, set the voltage of the working electrode to -1.3V~-1.7V, and perform electrochemical treatment The time is 60 minutes to 65 minutes, that is, the removal of trivalent Sb is completed.

specific Embodiment approach 2

[0024] Embodiment 2: This embodiment differs from Embodiment 1 in that the model of the electrochemical workstation described in step 1 is CHI760E. Others are the same as the first embodiment.

specific Embodiment approach 3

[0025] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the carbon cloth described in step 1 is the carbon cloth obtained after HCP331N hard conductive hydrophilic carbon cloth is processed. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com