Preparation method of high-concentration liquid silicon fertilizer

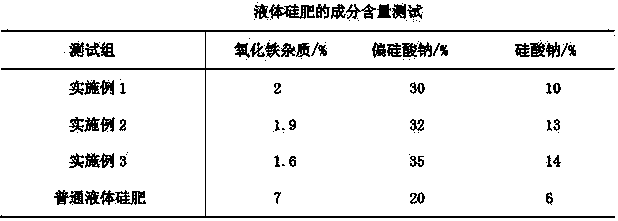

A liquid silicon, high-concentration technology, applied in liquid fertilizers, fertilization devices, fertilizer mixtures, etc., can solve the problems of low concentration of water-soluble silicon, insufficient utilization of silicon components, high impurities in prepared products, etc., and achieve high fertilization efficiency and good effect , the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

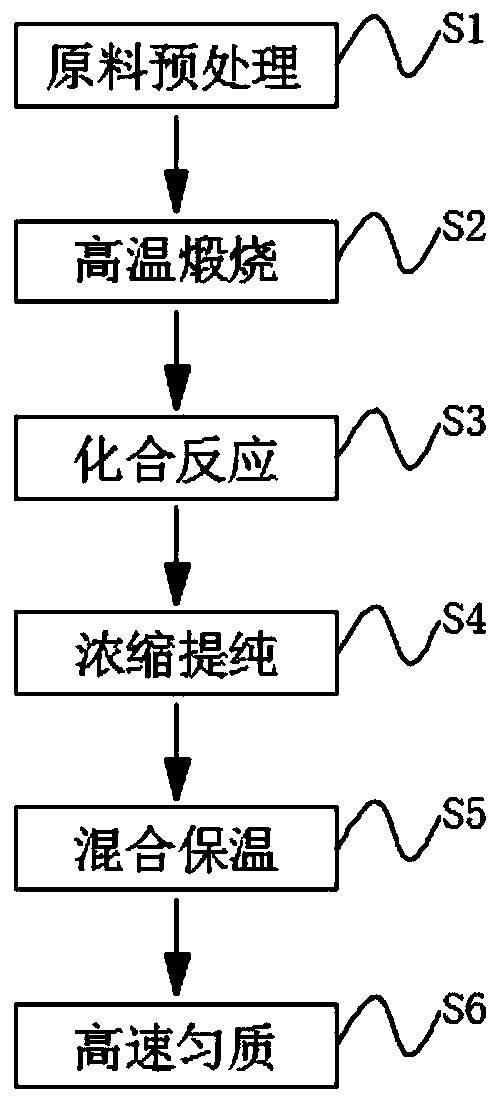

[0023] The preparation method of the high-concentration liquid silicon fertilizer of the present embodiment is carried out as follows:

[0024] S1: raw material pretreatment: in parts by weight, take 60 parts of potassium feldspar minerals and pure water and place them together in an ultrasonic cleaning machine for cleaning, and then dry them after cleaning, crush and grind the dried potassium feldspar minerals, The fineness of the grinding is controlled at 80 meshes, the cleaning frequency of the potassium feldspar mineral is 2 times, and the slime content of the potassium feldspar mineral after cleaning is 0.9%;

[0025] S2: High-temperature calcination: the potassium feldspar mineral ground in step S1 is placed in a calcination furnace, and the calcination temperature is controlled at 2600 degrees Celsius. After the potassium feldspar mineral is vaporized, its vapor is collected and stored in a container for later use. When it is cooled and calcined at high temperature, an ...

Embodiment 2

[0031] The preparation method of the high-concentration liquid silicon fertilizer of the present embodiment is carried out as follows:

[0032] S1: Raw material pretreatment: in parts by weight, take 70 parts of potassium feldspar minerals and pure water and place them in an ultrasonic cleaning machine for cleaning. After cleaning, dry them, and grind the dried potassium feldspar minerals. The fineness of the grinding is controlled at 75 meshes, the cleaning frequency of the potassium feldspar mineral is 2 times, and the slime content of the potassium feldspar mineral after cleaning is not higher than 0.8%;

[0033] S2: High-temperature calcination: the potassium feldspar mineral ground in step S1 is placed in a calcination furnace, and the calcination temperature is controlled at 2800 degrees Celsius. After the potassium feldspar mineral is vaporized, its vapor is collected and stored in a container for later use. When it is cooled and calcined at high temperature, an auxilia...

Embodiment 3

[0039] The preparation method of the high-concentration liquid silicon fertilizer of the present embodiment is carried out as follows:

[0040] S1: Raw material pretreatment: in parts by weight, take 80 parts of potassium feldspar minerals and pure water and place them in an ultrasonic cleaning machine for cleaning. After cleaning, dry them, and grind the dried potassium feldspar minerals. The fineness of the grinding is controlled at 70 meshes, the cleaning frequency of the potassium feldspar mineral is 3 times, and the slime content of the potassium feldspar mineral after cleaning is not higher than 0.7%;

[0041] S2: High-temperature calcination: the potassium feldspar mineral ground in step S1 is placed in a calcination furnace, and the calcination temperature is controlled at 3000 degrees Celsius. After the potassium feldspar mineral is vaporized, its vapor is collected and stored in a container for later use. When it is cooled and calcined at high temperature, an auxilia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com