Invisible structure of anchor bar and application of invisible structure

An anchor bar and invisible technology, applied in the direction of building construction, construction, etc., can solve the problems of increased workload, difficulty in withdrawing formwork, damage, etc., to eliminate damage and repair process, enhance the appearance of concrete surface, and speed up the turnover speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solution of the present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings, but the protection scope of the present invention is not limited to the following specific embodiments.

[0040] It should be noted that, unless otherwise mentioned, the equipment used in the following examples can be purchased through commercial channels. For the sake of brevity, some conventional technical operations in this field are not described in detail, and these technical operations are generally performed according to conventional methods. It should be understood that those skilled in the art know the details of these technical operations and can reproduce them to achieve the final technical effect.

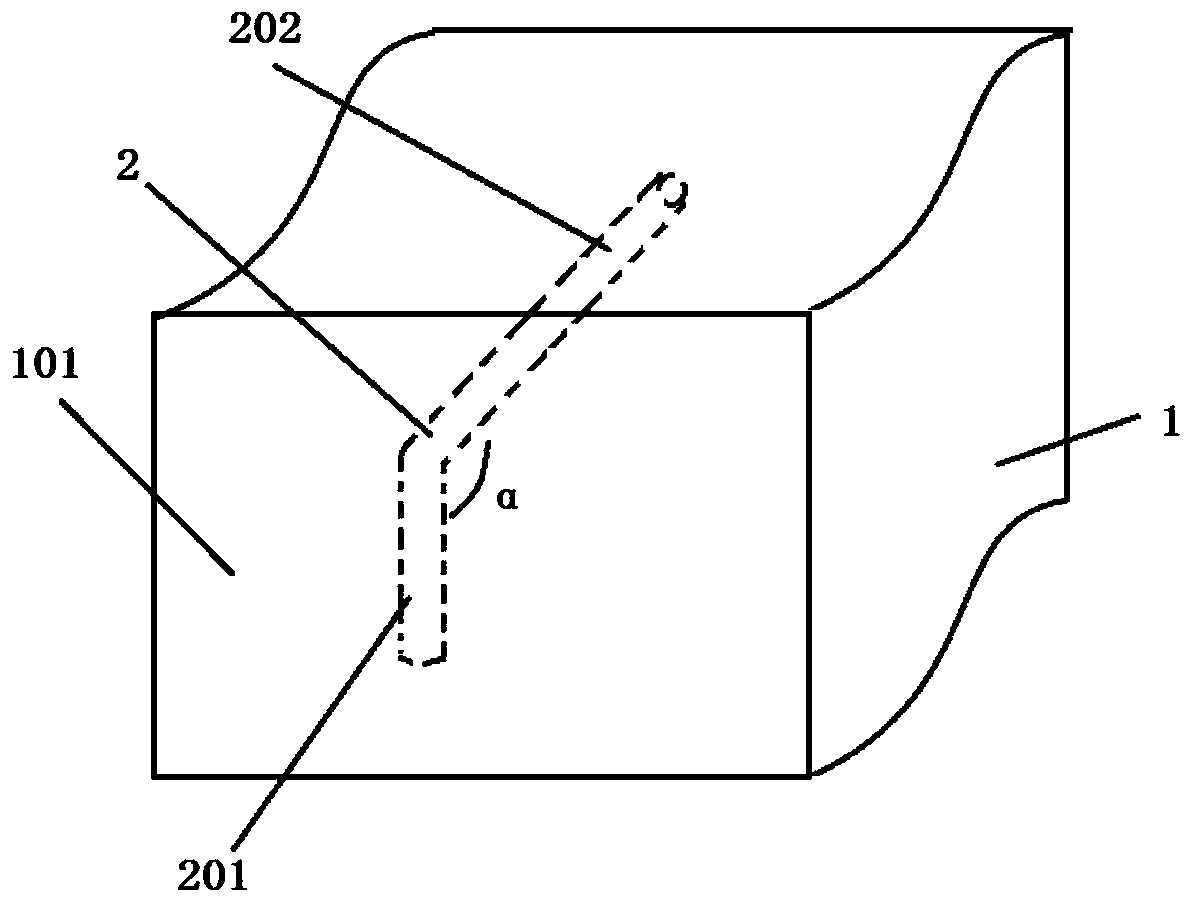

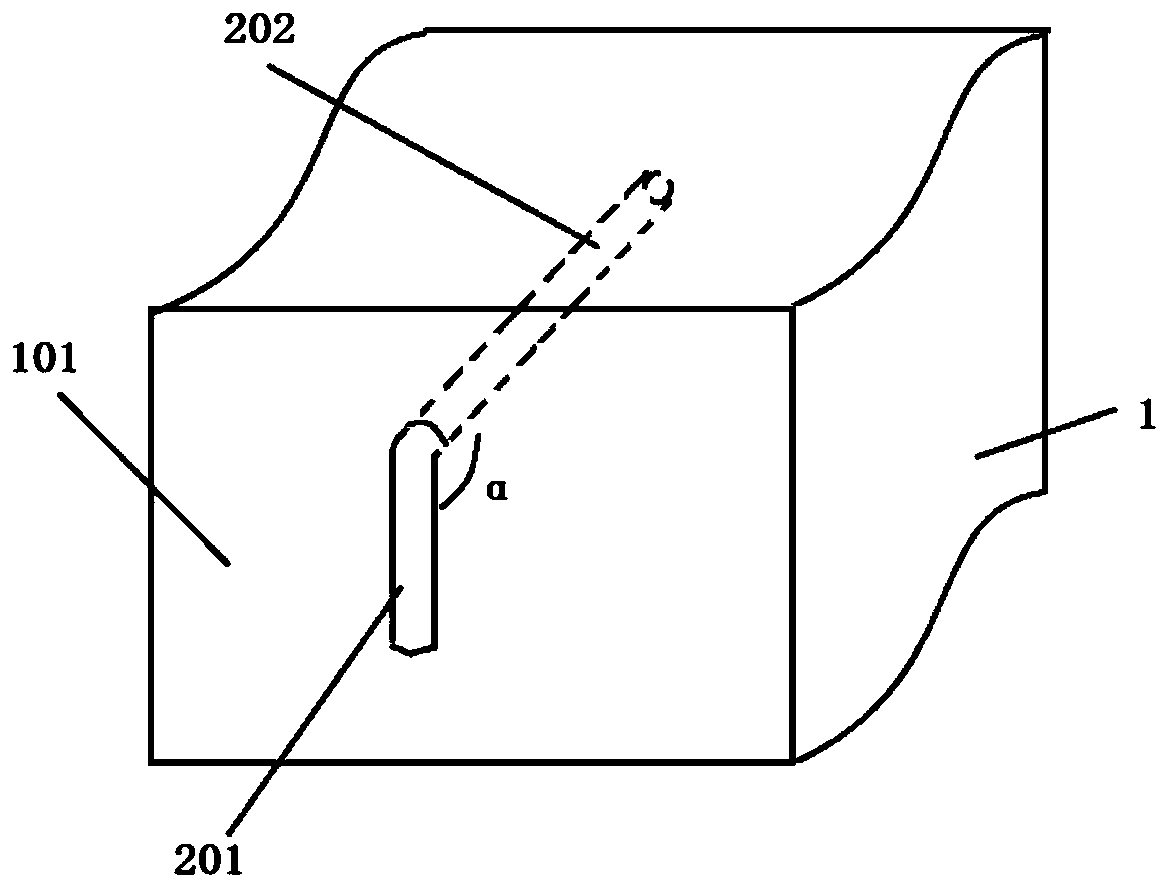

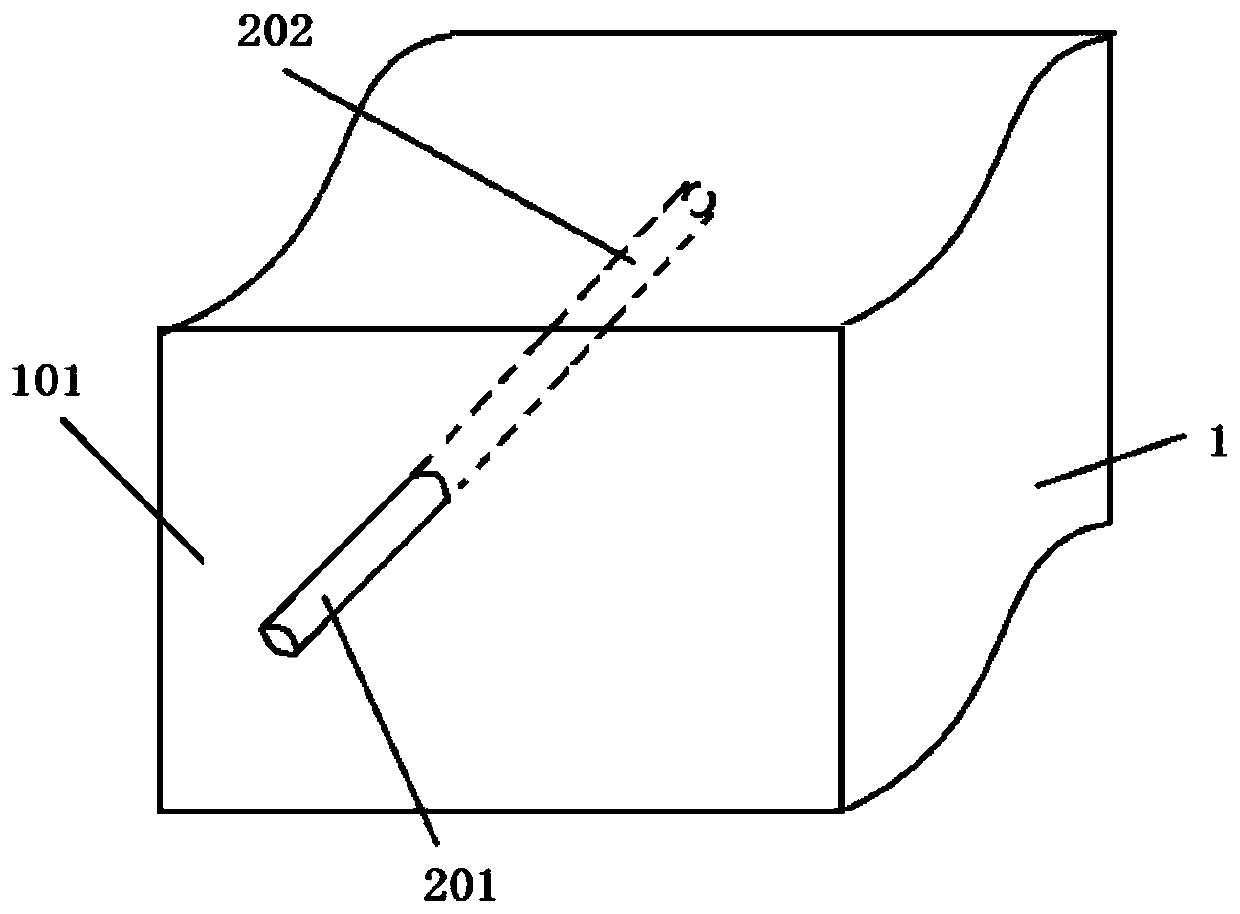

[0041] In the figure, the solid line shows the part that can be directly observed by the naked eye, and the dotted line shows the part hidden inside the structure that cannot be seen by the naked eye.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com